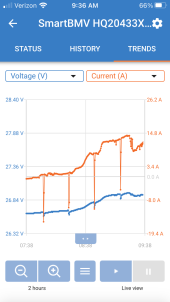

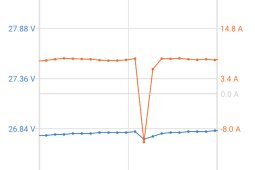

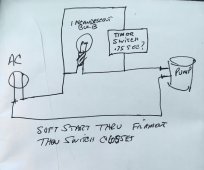

Hi. Our system current;ly is supporting a 120V residential sump pump, which cycles relatively frequently, perhaps hourly in wetter weather. The draw is 30+ amps. the inverter supports 40. I need to load more onto the system to get best use, yet have to duck around the startup surges to avoid co-incidental loads causing a trip. Load wise here we have lights and motors (other than tv/pc's). Do I buy /create a soft start for the sump pump, or are there other strategies. I suppose there could be a software solution, but with what kind of interface? Attached is a shot of the trends- you can see the regular draw of the sump pump, it is stormy now. On the readout I don't really see as dramatic hard start followed by a lower draw though.....thought I would. Pump runs about 50 seconds per cycle. Here's an edit- wondering if the Zoeller pump is drawing more than it is supposed to.

Attachments

Last edited: