K

its intended to take a DC input and put the DC Back out

Yes but it needs something to tell it to start and stop working. Normally this is voltage changes due to alternator increasing the starter battery volts.

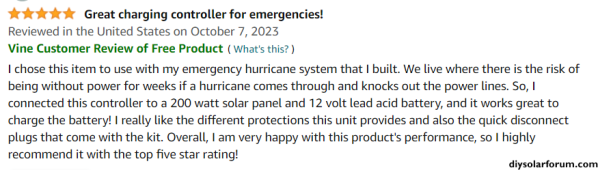

The MPPT controller section will work, no problem, but for solar controller as a stand alone unit, are are better engineered products on the market.

Take a step back and look at your requirements.

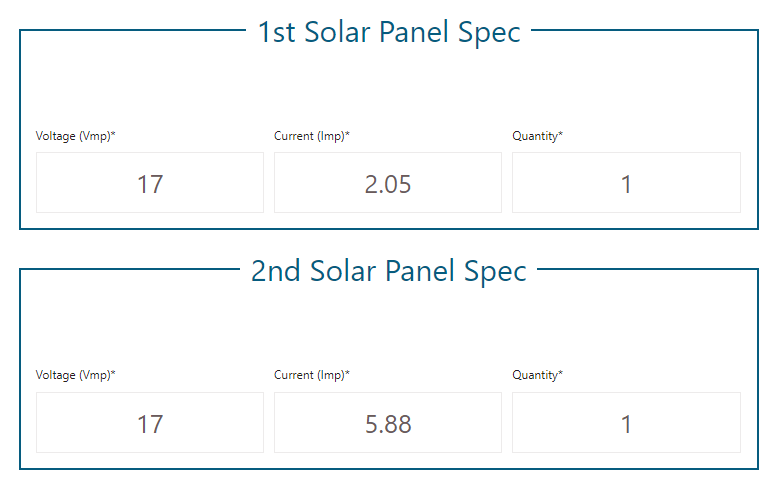

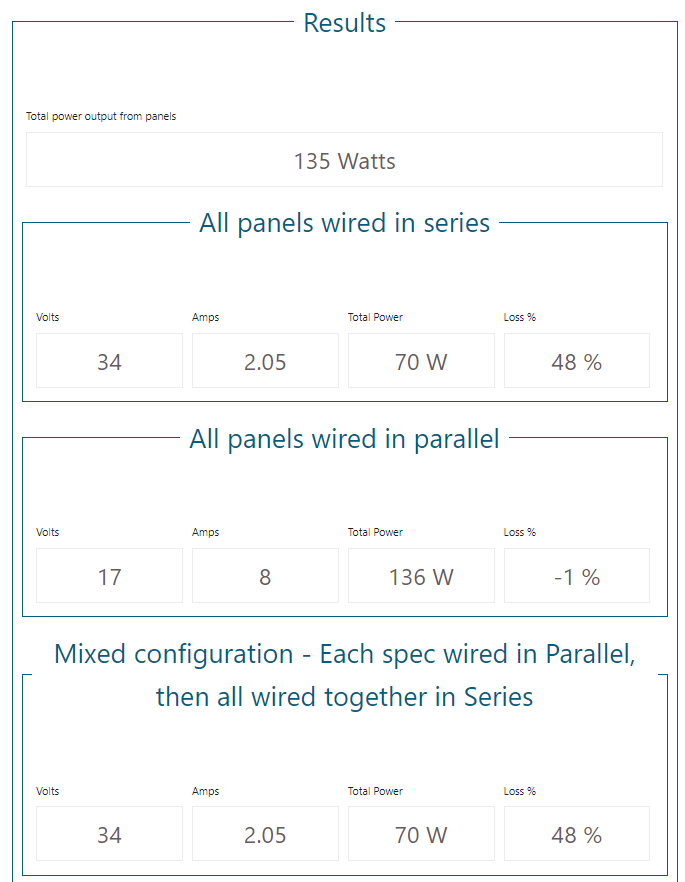

1, 200 watt panel to charge a LFP battery.

2, LFP battery to maintain starter and power starter battery loads

3, Hood panel to charge starter battery.

Rather than trying to use less than ideal products consider each task separately.

1, use a quality solar charger rated for 15 or 20 amps,

2, fit a program able DC to DC converter between LFP battery and starter battery set to 13.4 volts output. This unit has a control input so could be disabled / enabled as required. Not realy necessary as 13.4 volts is an ideal long term maintaining voltage.

3 fit a solar controller for the hood panel to starter battery, could be any type including a low cost PWM.