uksuntimes

New Member

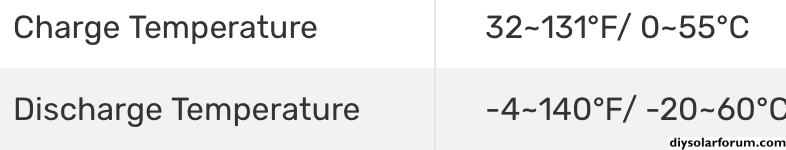

As part of rebuilding my car 12v solar/power system that I use for camping, I am looking address how I install/care for the battery itself.

We don't often get below freezing here, but it does happen.

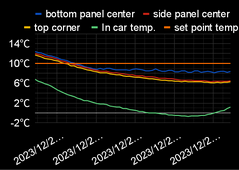

To that end, I have started looking at how I might warm my batteries. I've seen suggestions for heat pads, seed warming pads, tank warmers etc.

But alongside this, people also talk about building enclosures for the batteries, and then a wide mix of different insulation methods.

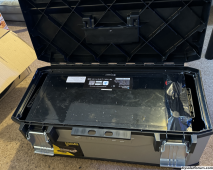

My question is, would it be suitable to use something already made as my enclosure to save a lot of extra materials and build costs.

I have discovered that there are lots of 'bags' available such as these (attached image).

Would getting one of these that fits my battery be a suitable approach? Perhaps even over sizing it, and then either adding some kind of thermal blanket or similar?

Or are there also suitable ready made 'boxes' that exist?

Or do I just have to bite the bullet and figure out how to make a box? Which then raises questions such as what materials, how to secure the battery inside etc.

I'm just starting my journey on the storage/warming side of things and the number of approaches, materials, problems and solutions is quite overwhelming.

For reference, my current battery is a 200ah Renogy with bluetooth, but no internal heating.

Ultimately I just want the simplest way to keep my battery at a good temp inside the car (seat area).

Any suggestions welcome. I will keep reading more of the posts on here that are available already as well.

We don't often get below freezing here, but it does happen.

To that end, I have started looking at how I might warm my batteries. I've seen suggestions for heat pads, seed warming pads, tank warmers etc.

But alongside this, people also talk about building enclosures for the batteries, and then a wide mix of different insulation methods.

My question is, would it be suitable to use something already made as my enclosure to save a lot of extra materials and build costs.

I have discovered that there are lots of 'bags' available such as these (attached image).

Would getting one of these that fits my battery be a suitable approach? Perhaps even over sizing it, and then either adding some kind of thermal blanket or similar?

Or are there also suitable ready made 'boxes' that exist?

Or do I just have to bite the bullet and figure out how to make a box? Which then raises questions such as what materials, how to secure the battery inside etc.

I'm just starting my journey on the storage/warming side of things and the number of approaches, materials, problems and solutions is quite overwhelming.

For reference, my current battery is a 200ah Renogy with bluetooth, but no internal heating.

Ultimately I just want the simplest way to keep my battery at a good temp inside the car (seat area).

Any suggestions welcome. I will keep reading more of the posts on here that are available already as well.

Attachments

Last edited: