timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,812

Several months.Google seems to have a wide range of answers, how long will a sand battery store useful heat?

It's seasonal storage.

Several months.Google seems to have a wide range of answers, how long will a sand battery store useful heat?

.

.Oh, clever, thanks for that! I was thinking I’d have to derive something from battery SOC.When you have excess, your string voltage is going up above MPP voltage.

Ditto!The controller looks at array voltage and when it goes over Vmpp it starts to divert power till the voltage drops back to Vmpp

It has to be a proportional design or it won't work well. The nice thing is that this is very inexpensive to implement. Even have one on my dishwasher heating element. Even the clothes washer runs off array power. I have 3,000W of panels, a 500W charge controller and a single battery for a very minimal system. I live better than others who spend five times more.Oh, clever, thanks for that! I was thinking I’d have to derive something from battery SOC.

Ditto!

If you are using Shelly plus, you could write a script to check forecast and automate your logicI run 2 mini splits and heat pump water heater as dump loads now. All can be controlled on my phone. I had been using 1 mini split and a few radiant heaters plugged into Shelley smart plugs that could also be controlled by the app on my phone. Come next winter, I will use both mini splits and use the radiant on very cold sunny days if there is excess.

Even with those in place, I still get excess solar production I am not able to use. I'm currently switching my shop to solar power and will run power thru a Chargeverter to the shop from the house and vice versa. Put it where it can be used.

If today is cloudy but good sun in the forecast tomorrow, I will run the battery bank down so the next day I can capture more. The battery bank doesn't need to reach full SOC, we might do laundry or run the dishwasher the sunny day. Plan ahead and you can capture more. Having options on loads that can be switched on/off will help maximize the yield. Some wonder how I can get by with 8.4Kw of PV for the house. It isn't hard if you do loads management and plan ahead.

The best dump load was adding the hybrid heat pump water heater ahead of the propane water heater. I can turn it on/off with the phone, set temp and with the extra hot water storage it extends how long we can go with limited sun.

If only the forecast was accurate.If you are using Shelly plus, you could write a script to check forecast and automate your logic

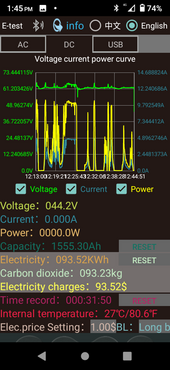

Nice, please tell us more about those dump controllers!I have three dump controllers all connected to water heaters. The first water heater is small and has priority getting any excess first to heat a small amount of water to serve most needs. The second is a slightly larger preheat tank for water. It has a lower priority and heats next or takes any extra power which the first tank can't use. The heating elements are small and it is possible to both on. The third 40 gallon tank heats water for the clothes washer and all cycles are done with hot water. The control is located a distance away from the others. No wire or wifi communication is needed. It is the dump of last resort and the array can never fully heat the tank. All controllers are proportional sending from 5 to 600W to each tank. No power is ever wasted. No batteries, charge controller or inverter capability is needed. The controller looks at array voltage and when it goes over Vmpp it starts to divert power till the voltage drops back to Vmpp. Here is just one of the controllers and the diversion for a half hour of the laundry tankView attachment 211760View attachment 211761.

I have three dump controllers all connected to water heaters. The first water heater is small and has priority getting any excess first to heat a small amount of water to serve most needs. The second is a slightly larger preheat tank for water. It has a lower priority and heats next or takes any extra power which the first tank can't use. The heating elements are small and it is possible to both on. The third 40 gallon tank heats water for the clothes washer and all cycles are done with hot water. The control is located a distance away from the others. No wire or wifi communication is needed. It is the dump of last resort and the array can never fully heat the tank. All controllers are proportional sending from 5 to 600W to each tank. No power is ever wasted. No batteries, charge controller or inverter capability is needed. The controller looks at array voltage and when it goes over Vmpp it starts to divert power till the voltage drops back to Vmpp. Here is just one of the controllers and the diversion for a half hour of the laundry tankView attachment 211760View attachment 211761.

Maybe you could program your MK PV router to switch of your load, then sense export power with CT, and finally power your load regulated to match your measured export. Repeat every xx seconds. This way you divert only your excess.I have Victron MP 2 GX AC2 supplying small DB ( AC2 on /off at given voltage ) this supplies socket running convector heater directly and immersion heater on a contactor switched by aux relay from MP2 on/ off at slightly higher voltage than AC2. Then in summer the socket running convector heater has a changeover switch to supply socket in garage which runs a pool heater. Works a treat and keeps battery voltage between set voltages.

Also have a small AC unit to use further excess power, this is manual on / off, as this defaults to off if power is interrupted.

Next upgrade is arduino based relays - currently in R&D stage ( if anyone has any info on this would be good ) .

Also In R&D ( custom software ) is a MK3 PV router, this used to be brilliant with non victron/battery PV system, sensing export power with CT on main incomer & diverting to immersion/ heater, once victron / battery was installed it kept going into a loop of diverting more power with victron supplying more power until both where flat out with battery draining.

Method that I wrote above WOULD work, you just didn't mention about zero export restriction. So of course it doesn't work.That is one way, but generally export only occurs( and thus diverted power in that scenario) if battery near 100%, which is not ideal and as standard as I said it got into a loop of sensing export then diverting power, then MP would sense more power required until both flat out.

Plus when near 100% SOC MPPT's / MP start to throttle any DC charging ( MP set not to export due to grid tie restrictions).

I'm after a gradual ramp up of diverted / dump loads, basic example is - battery is at 60% and 30% of PV production is diverted, battery at 80% and 50% is diverted, battery at 95% and 95% diverted.

If MK3 PV router can be controlled from data from Victron MP the amount / wattage of diverted power is near on infinitely variable ( up to 3kw total ) to 2no. Separate loads.

I'm not the software guru, that is my sons department, but as any parent will tell you they do want they want when they want, so R&D is sometimes Lacking LOL.

There are dozens of ways to do this, none off the shelf. It costs more to do Rube Goldberg designs and they don't work as well.Nice, please tell us more about those dump controllers!