If anyone can help me understand what went wrong, and any mistakes that I am personally made can you please chime in. I built this system off grid and spent four+ months designing.

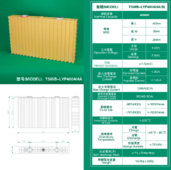

View attachment 194789

I’ve taught myself by watching videos from Will and others on YouTube. This forum has been a tremendous help. I consider myself a cautious intermediate though. Therefore I meticulously spent hundreds of hours planning and to be at this point is disappointing.

Here’s how the battery system was laid out when it failed. Docan’s engineer stated that the batteries were okay on their side in case someone’s wondering.

View attachment 194784

View attachment 194785

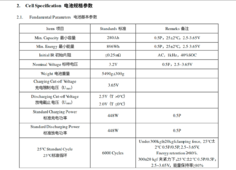

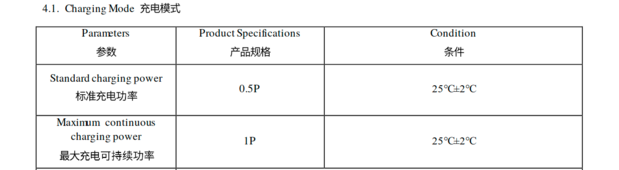

I’m not sure exactly what I did wrong or if this was an issue related to following the Apex assembly manual. It seems like many others are having fine experiences with these batteries. The SOC was at 140Ah I discovered. When building the system, Docan had told me that I couldn’t modify the BMS. Perhaps it was a misunderstanding. This time I have the app. I’ve been out in the desert for the last 10 days trying to fix this and I’m going home tomorrow defeated.

I discovered today that when the damage occurred in the battery, it must have also damaged three of the six inverters in parallel. 1,3, and 5 (all odd) are not working when I attempt to run them on their own. Or they were damaged trying to get the system back on during the last couple days. There was a strange, clicking noise once or twice when attempting to run the inverters without battery. Battery-less was one of the reasons why I chose this inverter. Here’s what I discovered today when running them each on their own:

Inverter 1: doesn’t appear to have any electrical connection to the batteries. It won’t even cold start with the batteries connected. Turning on PV gets it to start but it shows 0v for the battery. Setting 31 bAE, it attempts to activate the battery sending out 1A charge. But after a few seconds it clicks and I receive W15 - Battery Open - battery is unconnected or too low.

With the exact same settings, inverters 2, 4, and 6 work perfectly.

Inverters 3 and 5: these two are at least able to read the battery voltage and work when doing a cold start. However, a few seconds after turning them on, I receive fault code 32 – DC/DC overcurrent, battery, voltage fluctuates. 1) restart the inverter. 2) if error message still remains, please contact your installer.

I estimate that worst case the three batteries discharged around 20,000w ~417A / 139A each. More likely closer to 13,000w. It could’ve been more but the way I designed the system was to just run during the day. Originally, when I was designing the system, I was not going to include batteries, but decided that they may be helpful if a cloud rolls in. I never imagine them being the sole provider for the loads. So I figured that 3 Lifepo4 batteries would be sufficient to fill in the gaps. I have 224 250w solar panels that I bought used from Santan Solar. Everything would shut off in the evening and come back on in the morning. Perhaps in the morning or evening is when this occurred. I was able to adjust the load using a different raspberry pi from 10,000 W to 30,000 W as needed.

I initially installed solar assistant, but the communication cables were not reading properly. The original plan was for the raspberry pi controlling the loads to use MQTT from solar assistant and reduce the loads if too much power was being drawn from the batteries. With the coms cables being inconsistent, I based everything on hours of the day instead of the actual battery readings. This could have also been the issue. My temporary work around was in the morning it would start around 10,000 W gradually increasing to 25,000 W at solar noon and then back down to 10,000 W. There were times where the whole system would just shut off (mid-morning/early afternoon) and would stay off until the next day. I never understood why it wouldn’t restart.

Having the wrong solar assistant cables made it a guessing game. But I thought I was being conservative with the ramping up and ramping down it wouldn’t pull too much from the batteries. The lowest load setting was 10,000 W. I did not have the ability to turn off the equipment completely. In the evening that was definitely being pulled from the batteries once the sun went down. I had not experimented with the AC on/off time settings for the lvx6048wp. I would factor in weather, and if it was going to be a cloudy day, I’d just leave it on the lowest load setting around 10,000 watts.

It took me about a month to physically build everything. A friend was able to help me for two weeks. Hard labor, and a total of +20,000 pounds of wood, concrete, solar panels, and everything else.

View attachment 194786

View attachment 194787

I wish I had more time to be present during the testing, but that amount of time began to cause strain in my personal life. I even missed Thanksgiving.

Hopefully I can work with Watts247 to get the inverters fixed. And I’m not sure if Dan should be responsible or anything. May be hard given they’re in China and other people have not had issues with the box.

If anything needs, clarification, please let me know. Please understand that I’m just looking to find out where I messed up or if it was in fact, the actual battery failure. Spending a month in the desert is difficult, but I’ve been passionate about this project for the last year and a half. I may sound like I lost my marbles, but this has been something that I’ve enjoyed every second of planning and building. It’s disappointing now after all the work, it’s having issues. If I had to do it over again, I would go with overkill Solar BMS.

I’m going to get everything fixed. I just don’t want to repeat any mistakes that I could have unknowingly made along the way. Any help is appreciated. Thanks.