My skeptical flag is up on that one. How much compression, enough to deform the aluminum box? Surely not. So if not enough to deform the box, how is the "compression" transmitted to the jelly roll (or stack or pouches if that is what is actually used, we don't have a lot of data on that.) I wonder if "compression" is being conflated with "rigidity".compression is supposed to help prevent delamination of the jelly roll which in turn increases cycle life

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leaking Electrolyte from Bigbattery Powerblock

- Thread starter Will Prowse

- Start date

Indeed it is. I found "It is strictly forbidden to weld the battery directly."

(edit) "The battery case is positively charged. It is strictly forbidden to connect the negative pole of the battery and the battery case directly to form a path during use.This will cause the battery to short circuit, which may cause the battery to catch fire or even explode"

...or maybe leak electrolyte?

I posted earlier in the thread speculating that weld might be a cause but others who are certainly more knowledgable than I am (including Will) pointed out that welding is very common and produces much less heat than soldering which what the spec said was not to be done.

I wonder if the PDF translator picked weld instead of solder?

The truth is out there somewhere.

Or in other words, to force the pressure relief valve to operate. I like your term "restrict" a whole lot more than "compress". I totally get that restriction thing.The cells are not compressed but rather restricted to prevent or slow expansion of the cells by overcharge /overdischarge of the cell causing heat in the center of the cell which causes the electrolyte to turn to gas and expand with dramatic force.

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

This has been a long debated subject on the forum. Several threads running around about it. Summary, fixture with compression max of about 12psi helps increase cycle life thus prolonging the life of the battery. EVE spec sheet directly states > 2000 cycle life no fixture, >= 3500 with fixture.My skeptical flag is up on that one. How much compression, enough to deform the aluminum box? Surely not. So if not enough to deform the box, how is the "compression" transmitted to the jelly roll (or stack or pouches if that is what is actually used, we don't have a lot of data on that.) I wonder if "compression" is being conflated with "rigidity".

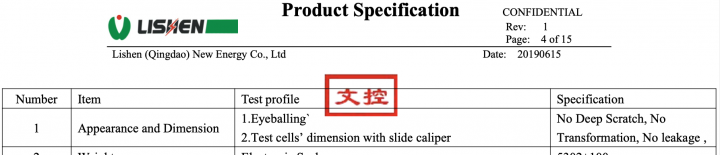

Edit: and the Lishen spec sheet

Last edited:

Is laser welding of weld-type terminals very common? Or is it usually spot welding?I posted earlier in the thread speculating that weld might be a cause but others who are certainly more knowledgable than I am (including Will) pointed out that welding is very common and produces much less heat than soldering which what the spec said was not to be done.

I am too and hopefully @Will Prowse will look at his cell and determine where the leak is. I would think he is interested and would also be interested in the well being of anyone who ordered from Big Battery.

I've watched the video dozens of times and now that I've learned that the "vent" is actually welded after the electrolyte I watched it again. It doesn't appear that the vents in either of the two bottom batteries had any anomalies with the vents. I'm also wondering if any of the other batteries upstream was actually the one that leaked but since the battery was vertical it leaked all the way down and puddled around the two bottom batteries over night. Will mentioned this possibility in his video as well.

Man, I want to get my hands on that thing and inspect it.

There are many threads regarding cell compression. You could start reading here. Cells do expand and contract and the idea is to keep the cell from expanding too much and some use springs with their fixture to accomplish it. Granted there is only around 1mm expansion per cell and personally I am not going through what's needed to do it properly.My skeptical flag is up on that one. How much compression, enough to deform the aluminum box? Surely not. So if not enough to deform the box, how is the "compression" transmitted to the jelly roll (or stack or pouches if that is what is actually used, we don't have a lot of data on that.) I wonder if "compression" is being conflated with "rigidity".

Most of the cell manufacturers claim a 2000 cycle life if the cell is fully charged and discharged at 1C rates. However a standard charge rate of .5C is recommended with the popular cells. Keeping the cells between the knees will extend cycle life. Anyways I am getting off topic.

It's marginally on topic. You can see from Will's dissassembly that the cells are loose in the metal case, with a millimeter or two of wiggle.Though it seems a remote possibility, this episode seems to consist entirely of remote possibilities. Somebody could say "but they dodn't compress, see what happened". I would say, no chance that's implicated, but what about that slight wiggle room, held firmly only by the battery terminals? Seems to me that vibration in transportation or a sharp blow could damage the terminals, maybe invisibly. Problem with this theory: the battery was apparently not in use when it leaked, therefore little to no current on the terminals. Still, needs to be considered.Anyways I am getting off topic.

Last edited:

Perhaps compression in the BigB case would help "protect" the cells by creating a single mass vs the friction fit? Heck even kapton tape the two groups of 4 together might be an improvement. They still need to do something about the spot welds on the shelf. That cant be a good thing.

From the looks of it the bottom case might even be an off the shelf product and then they have the top where the BMS and the Anderson connector lives.

From the looks of it the bottom case might even be an off the shelf product and then they have the top where the BMS and the Anderson connector lives.

I feel its pretty well established now that the cells you can buy from china are mostly refurbished cells. Likely initially used by the military and swapped when they get to something like 80% of initial capacity or 3 years whichever comes first. Cleaned up rewrapped hopefully tested for capacity and grouped together and that's why the variable capacities advertised for the same physically sized cells .

No offense, but source please?

I just noticed Item #1 on the Lishen test profile for the 272Ah cells. "Eyeballing for No Deep Scratch, No Transformation and confirming No leakage".

Not the exact same cells as the BigB 170Ah but I imagine that the test profile is very similar.

And the last item is to charge it and then drop it from 1.5m terminals down!

If this is part of the test profile, then perhaps Will just got unlucky and BigB shipped him a battery with some bad cells that wouldn't have passed the documented test profile. Hopefully, BigB learns from this and puts some quality processes in place to catch quality issues.

Attaching the entire test profile and warnings as a PDF.

Attachments

Last edited:

I bet they are now trying to decide if they have to do a recall. The expense of which could put them out of business. https://www.cpsc.gov/Recalls/2002/c...-flashlights-and-batteries-sold-in-kids-meals

Not really, they should have an E&O policy or a specific rider for product defects that should cover the cost.

Of course, if it's 11 defects out of 100K, I don't think that would qualify for recall action?

Now the sticky part is this: BB has been made aware of the issue, there is a video about it. And there is this thread and they claim to have done their investigations to understand the risk. If they knowingly hide the risk, and someone gets hurt, I can only imagine how this will turn out for them in court.

The defect rate doesn't really matter. It's the number of injuries that sets off recalls. That Halo Burger flashlight recall I attached happened because just two young children received "minor skin irritation" from the leaking toy flashlight battery. And those were simple alkaline batteries not Lithium. Fortunately Will wasn't injured. But even his call to poison control creates the sort of documentation that makes corporate lawyers lose sleep. You're right - if someone now gets hurt, BB is in a world of hurt after knowing about Will's problem. And an awful lot of startup companies don't have E&O policies because good policies are not cheap.Not really, they should have an E&O policy or a specific rider for product defects that should cover the cost.

Of course, if it's 11 defects out of 100K, I don't think that would qualify for recall action?

Now the sticky part is this: BB has been made aware of the issue, there is a video about it. And there is this thread and they claim to have done their investigations to understand the risk. If they knowingly hide the risk, and someone gets hurt, I can only imagine how this will turn out for them in court.

Last edited:

I am sure you know that's part of the safety specification Lishen performed to determine what the cell should be able to withstand without catching fire, exploding and other bad things. Items 12 through 16 refer to this on the spec sheet I have and that's why there is a star next to the number. EVE performed their drop test the same way.And the last item is to charge it and then drop it from 1.5m terminals down!

I am hesitant to blame Lishen until we have more information. But it seems from the other posts on the forum Big Battery needs to significantly improve their quality control and their assembly process.If this is part of the test profile, then perhaps Will just got unlucky and BigB shipped him a battery with some bad cells that wouldn't have passed the documented test profile. Hopefully, BigB learns from this and puts some quality processes in place to catch quality issues.

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

which was the same takeaway learned from Will’s last debacle with them.I am hesitant to blame Lishen until we have more information. But it seems from the other posts on the forum Big Battery needs to significantly improve their quality control and their assembly process.

Yup...I remember that and they did not listen.which was the same takeaway learned from Will’s last debacle with them.

None taken . I've seen the things mentioned myself . I've seen others pictures and read of their experiences here.No offense, but source please?

I have had a couple of disputes with Ali-express myself and ended with a refund for not being new cells .I have had two large cells die on initial charge and the seller refused to do anything about .Utube now has a flood of similar material .Please do your own research further . I can lead you to water but can't make you drink. Been using these cells for 5 years plus , have you? No offence meant.

Been using these cells for 5 years plus , have you? No offence meant.

I have 32 of them in operation since last year. Before that, I bought several to test in my lab. I've worked with LiFePO4 cells well before that, and did some of the first lab tests for use of LiFePO4 in telecoms applications with some of the very first commercially available LiFePO4 cells. These particular aluminium prismatic cells were not readily available 5 years ago - EVE's first version is from 2017 (maybe 2016). Aluminium cased cells are pretty new in general; before that there was Winston/Thundersky/Sinopoly which are/were not produced in the quantities we see today with the aluminium prismatic cells.

Last edited:

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,977

Very possible the line of batteries started out as a premium industrial product. Later, knock-offs and outright counterfeits by many manufacturers and recycled material being sold as new. That has happened with ICs. You've probably seen the video of "high tech" recycling involving a bonfire and smacking PCB to remove parts. Reels of parts sold through brokers, with a few fresh components at start of the reel, but bent leads on the ones in the middle.

But just plain old slipping quality control is the simplest explanation.

Materials get sourced from cheaper suppliers and less skilled labor with less oversight and testing. If later lots aren't also put through qualification/life testing, no one will ever know anything changed until something shows up in the field.

I think counterfeit cell phone batteries were showing up in the official supply chain some years back, when exploding phones and laptops was all the rage (just about when Tesla Roadster was introduced, using laptop batteries.) I chose not to buy the stock. Ergo, I work.

www.marketwatch.com

www.marketwatch.com

But just plain old slipping quality control is the simplest explanation.

Materials get sourced from cheaper suppliers and less skilled labor with less oversight and testing. If later lots aren't also put through qualification/life testing, no one will ever know anything changed until something shows up in the field.

I think counterfeit cell phone batteries were showing up in the official supply chain some years back, when exploding phones and laptops was all the rage (just about when Tesla Roadster was introduced, using laptop batteries.) I chose not to buy the stock. Ergo, I work.

TSLA Stock Price | Tesla Inc. Stock Quote (U.S.: Nasdaq) | MarketWatch

TSLA | Complete Tesla Inc. stock news by MarketWatch. View real-time stock prices and stock quotes for a full financial overview.

Similar threads

- Replies

- 14

- Views

- 675

- Replies

- 4

- Views

- 3K