So now there have been a total of 13 cells leaking. Big Battery discovered 11,

I wonder if "discovered" really means "got report from customer".

The manufacturer, Lishen, has told Big Battery it's ok to mount the cells on the sides.

They may need to update that guidance. One thing they can't do is stay silent on the question.

A properly sealed vent will not leak.

It can leak fluid when gas vents, or else it relies on some hitherto unknown physical principle.

This has me wondering if Lishen had some bad quality control. Or something else is happening but I don't know what that could be. I do find all of this very odd to say the least.

And it's not just Lishen and Bigbattery with a stake in this, it's the whole DIY battery scene. It is no longer possible to claim that leakage is a rare issue, so how do you build a battery that doesn't leak? Just control the cell orientation? Subject all cells to extended testing in desired orientation? Switch suppliers? That last ought to get Lishen's attention.

This is most likely a situation of welds that had a defect. The electrolyte would leak out only if cell tilted until it covered the defect and then temperature/pressure cycled.

Plausible, except that pressure would not be required, only tilting. So to expand: the can was imperfectly welded but was always shipped and stored vertically so that the leak was not discovered by assembly time. This theory should have been tested by now by Bigbattery, but apparently not or they would have said something about it.

Riddle me this: if Bigbattery found 11 leaking cells then why don't they tell us whether it is the can or the vent that leaks? Maybe because if it's the vent then it looks like Bigbattery's design flaw, which they don't want. Or if it's the can then it looks like they picked the wrong supplier and it's really hard to change, at least in part because they might not be able to get the same physical dimensions. Or they don't know, and that looks even worse. So just stay silent on that and hope it blows over, which unfortunately it did not.

Alternative possibility is corrosion, which would escape an initial test. Disassembling failed cells should show what happened, and ought to be done.

It sure should. But consider: how do you test a cell for hermetic seal after disassembly? Challenge.

As I wrote earlier, QC could include gross leak test: pressure bomb then dunk under DI water and look for bubbles.

Sounds good. Should Will give the "evidence" back to Bigbattery and trust that they will do exactly that?

Here's an off the wall idea: add an accelerometer chip to the BMS so it can know if the cells were ever inverted or dropped. Have a pressure sensor too so it can know that history, and a temperature sensor so it can know if it's on fire even without the external thermistor. If Bigbattery is willing to throw in a cute gizmo like the tiny fire extinguisher, I would value such a "black box" far more.

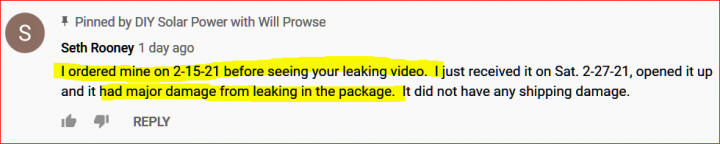

I dunno. The neverending saga. Given what is shaping up to be a statistically high failure rate, there should be enough DIY Lishen builds out there by now to regard the lack of problem reports as meaningful. But how many tried the sideways orientation? Every photo I've seen has the cells vertical. Bigbattery would seem to be the only product out there explicitly designed to orient prismatic cells horizontally. That's the thing about pioneering: you can end up with arrows in your back.