WYtreasure

It's not happy hour, I'm just like this.

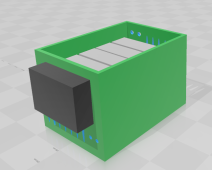

Disconnect switch:

One of my favorite subjects. I read the page linked. Nowhere do they refer to "under load" when it comes to switching. I think most folks believe it is acceptable to use the switch to stop current. I am not one of those believers. A much better, safer switch costs about $50

Here is something for your reading enjoyment.

One of my favorite subjects. I read the page linked. Nowhere do they refer to "under load" when it comes to switching. I think most folks believe it is acceptable to use the switch to stop current. I am not one of those believers. A much better, safer switch costs about $50

Here is something for your reading enjoyment.

Amazon.com: Customer reviews: Ampper Battery Switch, 12-48 V Battery Power Cut Master Switch Disconnect Isolator for Car, Vehicle, RV and Boat (On/Off)

Find helpful customer reviews and review ratings for Ampper Battery Switch, 12-48 V Battery Power Cut Master Switch Disconnect Isolator for Car, Vehicle, RV and Boat (On/Off) at Amazon.com. Read honest and unbiased product reviews from our users.

www.amazon.com