Thanks! Now that I've thought about this I've realized I can just put all my 16 cells in series forming a 48v system. Even better since I can then use cheaper hardware and and charger.No... the BMS will expect all the cells in series.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wiring 16 cells into 24v battery???

- Thread starter shaymcquaid

- Start date

Letdasunshine

New Member

- Joined

- May 5, 2021

- Messages

- 4

What the benefit of the second updated photo from the first? Is there more ah's?With 16 LiFePO4 cells, you can get 24 volts a couple ways:

View attachment 7074

Edit: Updated 2P8S image

View attachment 7076

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

This gets into the old debate of Serial-First (The first photo) vs parallel-first (The 2nd photo) At the top level there is no difference. However, there are pros and cons to both layouts. I prefer the second because of the simplicity (Only one BMS). Others prefer the first because of the redundancy (2 BMSs) and the ability to watch individual cells. You may want to look at this resource. I try to lay out some of the pros and cons.What the benefit of the second updated photo from the first? Is there more ah's?

Cell Configurations for 12V 24V and 48V LiFePo4 Batteries

This short deck shows 1P and 2P cell configurations for 12V, 24V & 48V LiFePO4 batteries. To get the deck, click on the orange button at the top of this page. Note: Reviews, Comments and corrections are welcome Document Revision History...

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

Another downside of the 2p8s configuration is that the BMS will have to balance cells that are effectively twice the capacity.What the benefit of the second updated photo from the first? Is there more ah's?

My Overkill 8s bms maintains the top balance of my grade b 280ah 8s1p battery.

I suspect it would not be able to maintain top balance for a 2p8s 560ah battery of similar quality cells.

Last edited:

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

With 16 LiFePO4 cells, you can get 24 volts a couple ways:

View attachment 7074

Edit: Updated 2P8S image

View attachment 7076

So. How does this look and am I matching up equipment properly?

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Two things caught my eye.So. How does this look and am I matching up equipment properly?

View attachment 131463

1) Check the voltage limits on the charge controller input and make sure it can handle the voltage from 10 panels in series. Note: Be sure to adjust for cold temp when calculating the array voltage.

2) Make sure the breaker on the output side of the charge controller is bidirectional.

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

Two things caught my eye.

1) Check the voltage limits on the charge controller input and make sure it can handle the voltage from 10 panels in series. Note: Be sure to adjust for cold temp when calculating the array voltage.

2) Make sure the breaker on the output side of the charge controller is bidirectional.

Great feedback FilterGuy, thank you.

1) Per the manufacturer of the charge controller, at 24v, it can handle up to 1040 watts. So I think I'm good there.

2) In reviewing the details on the breaker I bought from Amazon (https://www.amazon.com/gp/product/B07HG5YR77/ref=ask_ql_qh_dp_hza) I don't see it indicated that it is bidirectional, so I posted a question and will await an answer. If I don't hear back I'll find another one that is labeled as such.

Really appreciate the feedback!!

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

Two things caught my eye.

1) Check the voltage limits on the charge controller input and make sure it can handle the voltage from 10 panels in series. Note: Be sure to adjust for cold temp when calculating the array voltage.

2) Make sure the breaker on the output side of the charge controller is bidirectional.

Also I was curious if you had any thoughts on what size circuit breaker I should use between the 3000w inverter, and the battery bank? Currently I have a 40amp. In reading online (https://www.renewablewise.com/how-many-amps-does-a-3000-watt-inverter-draw/) it would seem I need a 175amp, which seems excessive to me.

MisterSandals

Participation Medalist

You misunderstood. You need to check your SCCs "max solar input voltage". 10 panels in series is quite high (sum of all Voc for panels in series).1) Per the manufacturer of the charge controller, at 24v, it can handle up to 1040 watts. So I think I'm good there.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Also I was curious if you had any thoughts on what size circuit breaker I should use between the 3000w inverter, and the battery bank? Currently I have a 40amp. In reading online (https://www.renewablewise.com/how-many-amps-does-a-3000-watt-inverter-draw/) it would seem I need a 175amp, which seems excessive to me.

Calculating Inverter DC Wire & Fuse Size

Note: Click on the Orange 'Download' button at the top of the page to get the paper. When designing a system, some of the most critical connections are the big wires to the inverter. The best advice is to do what the inverter manual says, but...

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

You misunderstood. You need to check your SCCs "max solar input voltage". 10 panels in series is quite high (sum of all Voc for panels in series).

I'm assuming you mean "max VDC", on the SCC it is 100VDC

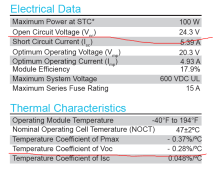

I've attached the spec sheet on the solar panel, as I'm not sure what number to look at.

Attachments

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

The Voc is what you need to look at. As you put the panels in series, the voltage adds.I'm assuming you mean "max VDC", on the SCC it is 100VDC

I've attached the spec sheet on the solar panel, as I'm not sure what number to look at.

So 10 panels in series will have a voltage of 243V at 25deg C. As it gets colder, the voltage will go up.

Adjusting Solar Panel Voc for temperature

When designing you solar panel system, it is important to adjust you solar panel Voc for temperature in order to ensure you do not over-voltage the PV inputs of your solar charge controller. This paper shows how to calculate the Temperature...

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

The Voc is what you need to look at. As you put the panels in series, the voltage adds.

View attachment 131468

So 10 panels in series will have a voltage of 243V at 25deg C. As it gets colder, the voltage will go up.

Adjusting Solar Panel Voc for temperature

When designing you solar panel system, it is important to adjust you solar panel Voc for temperature in order to ensure you do not over-voltage the PV inputs of your solar charge controller. This paper shows how to calculate the Temperature...diysolarforum.com

So the SCC is too small for this size array at 100vdc, since the panels need 243voc, am I interpreting that correctly. I find it weird they use two different figures to match systems...

MisterSandals

Participation Medalist

Your SCC can charge at 40A max.So the SCC is too small for this size array at 100vdc,

40A x 28V charging = 1120W

Max input voltage is one of the more important numbers to consider when buying an SCC and matching panels.since the panels need 243voc,

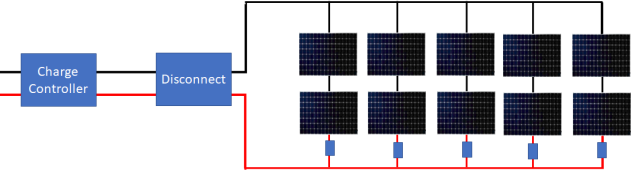

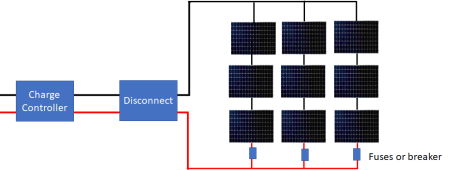

Since you've already purchased your equipment, you need to look at it the other way around. You need to arrange your panels in a combination of series and parallel to stay below your SCCs max input voltage.

With a Voc of 24.3V you can only get 3 in series to stay below 100V.

A good choice would be to put 3 panels in series, 3 times to make 3 strings. Put these strings in parallel. You can use standard MC4 3:1 Y connectors for the parallel connections.

There is not much you can do with the 10th panel other than get a second (redundancy is good) SCC.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

The controller has a specification for the max voltage it can handle.I find it weird they use two different figures to match systems...

The panel specifies the voltage each panel can create.

It is up to the designer to match the layout of the panels to the capabilities of the charge controller.

For this case, the controller can handle 100Vdc and each panel can produce 24.3V at 25deg C.

Therefore, at 25deg C, there can be up to 4 panels in series. (4 x 24.3V = 97.2V < 100V)

However, as the temperature goes below 25degC the temperature will rise. 3 panels in a series will create 72.9V and there is plenty of margin to cover cold temperature rise.

Note: please review this to learn how to calculate cold temperature rise of Voc:

Adjusting Solar Panel Voc for temperature

When designing you solar panel system, it is important to adjust you solar panel Voc for temperature in order to ensure you do not over-voltage the PV inputs of your solar charge controller. This paper shows how to calculate the Temperature...

To get more than 3 panels on the controller, they need to be arranged in a serial-parallel arrangement. There are a couple of possibilities for this particular combination.

The 2nd one only uses 9 panels... but since the strings need to be balanced, the options are limited.

To calculate the fuse/breaker sizes, please review this:

Fusing & Wire Sizing guidelines for solar panels

To get the paper, click on the orange'' button at the top of the screen. This resource is intended to help the user understand when they need to add Over Current Protection Devices (OCPDs - Fuses or Breakers) to the solar panel array and what...

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

Your SCC can charge at 40A max.

40A x 28V charging = 1120W

Max input voltage is one of the more important numbers to consider when buying an SCC and matching panels.

Since you've already purchased your equipment, you need to look at it the other way around. You need to arrange your panels in a combination of series and parallel to stay below your SCCs max input voltage.

With a Voc of 24.3V you can only get 3 in series to stay below 100V.

A good choice would be to put 3 panels in series, 3 times to make 3 strings. Put these strings in parallel. You can use standard MC4 3:1 Y connectors for the parallel connections.

There is not much you can do with the 10th panel other than get a second (redundancy is good) SCC.

I should have thought this through. I think what I will do is use 8 panels, run them in two sets of 4 in series, then run those two sets in parallel. That will keep me under then 100vdc mac and 40amp max for the SCC. THANK YOU!

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

With 4 in series, if the temperature drops very much below 25degC (77F), the voltage will get too high. Please review the resource I linked to in my previous post.I should have thought this through. I think what I will do is use 8 panels, run them in two sets of 4 in series, then run those two sets in parallel. That will keep me under then 100vdc mac and 40amp max for the SCC. THANK YOU!

McLovin

New Member

- Joined

- Feb 8, 2021

- Messages

- 93

With 4 in series, if the temperature drops very much below 25degC (77F), the voltage will get too high. Please review the resource I linked to in my previous post.

You're right, 3 in series makes more sense for the cold. I'm in a cold climate, southern Colorado, at 7400 feet, however, what about the fact that there is less sun, and it's at a different angle? Wouldn't that mean there would be less voltage as a result? I can live with 9 panels.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Short Answer: NOYou're right, 3 in series makes more sense for the cold. I'm in a cold climate, southern Colorado, at 7400 feet, however, what about the fact that there is less sun, and it's at a different angle? Wouldn't that mean there would be less voltage as a result? I can live with 9 panels.

Longer answer,

When the batteries are full, the solar charge controller effectively 'disconnects' the panels... letting them drift to their Voc (Open Circuit Voltage).

It turns out that it takes very little light for a panel to generate the full open circuit voltage. People have reported seeing Voc at dusk after the sun is below the horizon. Consequently, even if the panels are at a terrible angle, they are likely to experience the full open circuit voltage.

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

If you don't mind my asking, why didn't you?I should have thought this through.

Your answer may help someone else.

Similar threads

- Replies

- 6

- Views

- 243

- Replies

- 12

- Views

- 576