I've seen comments on the forum suggesting that, given a string with load connected in the diagonal manner, there might be a benefit to making the load connections more toward the middle of the string rather than at the very corners. For the 4 battery parallel string that would be done like this:

Setting the initial parameters back to: battery IR of 5 milliohms, link resistance of 1 milliohm, load current of 100 amps, the calculation gives this result for the theoretical battery currents in amps:

Example 8

20.8333

29.1667

29.1667

20.8333

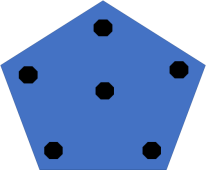

Compare this to Example 4. The values of the currents are exactly the same, but distributed among the batteries in kind of an anti-symmetric way. When I saw this, I thought "I wonder if there is a way to make a connection halfway between the two methods?". Consider the link cable between the negative terminals of battery 1 and battery 2. At a point halfway between the ends of the cable strip away an inch of insulation and expose the copper conductor. Connect the negative load cable at that point. I know this is impractical but bear with me. Now in a similar manner expose the conductor at a point halfway between the ends of the link cable connecting the positive terminals of battery 3 and battery 4; connect the positive load cable at that point. It should be as illustrated in this image:

Now with 4 identical batteries having indentical IR of 5 milliohms, link cable resistance of 1 milliohm and load current of 100 amps the calculation shows that the battery currents in amps are:

Example 9

25.0

25.0

25.0

25.0

We have (theoretically) perfect balance! Is this a previously unknown connection giving perfect balance, like the "Halfway" connection shown in the Victron document? Does anyone know if this been published anywhere?

A very practical way of making this connection is possible when busbars are being used. Just drill a couple of holes at points on the busbars at the pertinent points halfway between the appropriate battery terminals and make the load connection there. This image shows what I mean:

The usual diagonal connection would be as shown with the red and black wires. The new connection would be as shown with the yellow and blue wires.

Even more useful are the following properties. For this new connection, it doesn't matter what the battery IR is!! The calculation of the battery currents remains (theoretically) perfectly balanced for any value of IR as long as all 4 batteries have the same IR. This is very handy because as the batteries are discharged, their IR will change but this change will not upset the (theoretical) perfect balance. Also, the resistance of the links has no effect on the (theoretically) perfect balance! This means that the busbar need not be very thick copper; it can be thinner and higher resistance than would normally be needed for good balance. The only restriction is that its resistance shouldn't be so high that it gets too hot.

A mathematician would say that the (theoretically) perfect balance is invariant with respect to battery IR and link resistance. These properties are crucially dependent on the batteries having identical IR.

I expect that some reading about this may be skeptical. I was skeptical myself at first, but I've checked it several times. I invite verification by members of the community. Perhaps someone will do a simulation with Spice. The ultimate proof would be a hardware proof. If someone already has a string of 4 identical batteries in parallel with busbars, they could drill the two new holes and connect the load there, subsequently checking the balance.