For 24V, you would use 8 cells in series which in your case would be 24V/90AH each pack. You would then parallel the packs into a complete bank, so 4 packs of 24V/90AH for a total of 24V/360AH gross. Each pack, of course, should have an 8S BMS and it's own fuse.

The BMS decision depends on your usage and how many amps the system will pull from the batteries.

Example: 100A off 24V system which amounts to 2400 Watts, 4000 Watts translates into 166A @ 24V

(Watts ÷ Volts = Amps. Amps X Volts = Watts) to keep it simple.

There are many types of BMS', the most common are FET Based units such as Daly, ANT BMS, DYKB BMS, and other "Smart BMS' " which people use here with good results. As a general rule with FET based units, it is best to oversize them by 25% of what you expect your max amp draw to be, so you never take them to the edge of their specified max amps.

I will not recommend a BMS to you, as it is somewhat subjective, I do use Chargery BMS8T-300's for my packs using Deltec 500A/50mv Shunts and external 200A Energy Saver Contactors (relays), which is a different beast and dis NOT FET Based... Approximate cost is about $150 USD (I bought shunt & relays separate and my costs are different due to what I have been doing).

Link to BMS8T for info: https://chargery.com/BMS8T.asp

UN-OFFICIAL Chargery BMS8T Draft 4.1 Owners Manual.

https://diysolarforum.com/attachments/chargery_bms8t_owners-manual_v4-1-pdf.15938/

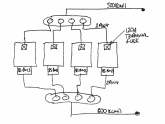

With the BMS', they should all have matched settings (better if you can modify the configs yourself) so no single BMS acts differently than the others. The next MOST CRITICAL is ensuring the battery bank is properly wired and configured so that the Discharge Load and Charge Capacity is as balanced as possible. Refer to this document for extended details.

https://www.victronenergy.com/upload/documents/Wiring-Unlimited-EN.pdf

The TRICKY PART !

Now assume you setup for 200A max draw capacity which on a 90AH pack is over 2C rate (which is not necessarily what the cells can handle) as standard LFP cells usually max out at 1C or in this case 90A on a 90AH battery. VERY IMPORTANT TO NOT EXCEED CELL SPECS ! But with packs properly balanced in the pack they should load share that out. The lurking GOTCHA (like the ookpik lurking in the woods) is to setup the "packs" to be able to operate as a single battery should the others shut-off for some reason. This is harder (near impossible) to do with smaller capacity cells such as 90AH.

Keep in mind that a BMS is the Last Ditch Safety System and the BMS should NOT be responsible for stopping charge or discharge but rather that is the job of the SCC ( Solar Charge Controller) and the Inver/Charger System, which should shutoff just before the BMS forces it. This also requires that the system be Voltage Calibrated as well so everything reads properly and acts accordingly (see link in my signature related to that).

Hope that helps,

Good Luck

Steve