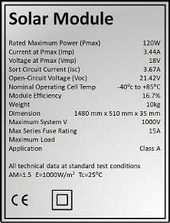

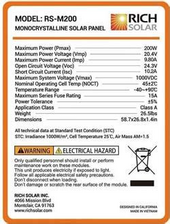

We prefer to design around label specs, not measurement. Specs are tested in a lab with one full sun; field measurement is affected by conditions.

Double-check with measurement.

Though good advice, the double-checking is important.

I have a small 12V, 6-panel setup. My panels clearly state on them that they have a short-circuit-voltage of 19V.

I wondered why my charge controller (which is 12/24/48V compatible) would occasionally go into "standby" even though it was reading PV and the batteries were nowhere near charged. I checked cabling, over-temperature, battery BMS, etc. and could attribute nothing to it. I even fitted temperature-activated, battery-powered ventilation to the box it's in and bought a thermal camera.

Then I realised the cause - the panels are actually giving 22-24V at times.

This is despite them all being in parallel (through long individual runs coming to a combiner box, so I'm able to measure each panel, in effect), being in the UK (not sure how I'm maxing them out with this amount of sun!) and having cable runs long enough that it should be pulling the voltage down somewhat.

For a tiny setup, I was surprised that the panel's specs (and I checked each panel individually, plus the original purchase, plus I retained the manuals) were so far out.

It also doesn't directly correlate with weather - but it mostly only happens on sunny days, not hot days, and I think another poster nailed it - it's to do with temperature CHANGE as much as the actual temperature.

It's more an inconvenience than a danger, and the charge controller is sensible enough to just cut them off briefly and then resume a minute later, but it does mean I'm throwing energy away during that time.

The cabling is otherwise vastly over-specced (which may contribute a little as the voltage-drop is less than expected? But then on a 12V system, my currently voltage drop is probably the worse it will ever be!).

I'm hoping that - as I have planned - when I move to 24V / 48V, the over-spec will not contribute as much in terms of percentage and the controller will handle it more happily, but a panel specifically stating a Voc of 19V? Yeah, don't believe it, no matter how many times it's written all over everything.

Fortunately, my entire system is built on "overspec and under-utilise" principles so everything is able to handle higher voltages and currents than necessary (the charger controller just sees a 12V battery and a 24V solar and gets confused, I think), but I was never expecting a bunch of 19V panels in parallel to be able to hit 24V, especially when they are on opposite sides of the house and at least one is shaded at any time of the day.