You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best practice for 300kgf ‘fixture’ 280Ah cells

- Thread starter fafrd

- Start date

Bob B

Emperor Of Solar

- Joined

- Sep 21, 2019

- Messages

- 9,207

He is not quite thru the full range yet .... We'll see where he ends up.Average movement is what I am interested it (average of all four springs)

It is less than the 20 in-lb my 1/4" drive torque wrench is able to measure.Out of curiosity, using a torque wrench, i'd love to know what torque it would take in Nm to release that nut, while you had it under 11.5PSI

That is really not an acceptable way to determine how much pressure you are putting on your cells. I am using springs and use the a defined preload compression distance on the springs to set the force. That is the only practical way I know of to do this. I am using one of these to measure this force.

LWMH1 Load Washer Load Cell with Mounting Holes - Thru-Hole Load Cell

LWMH1 Load Washer Load Cell with Mounting Holes- Thru-Hole Load Cell is designed for use in force applications. This product is constructed from aluminium and is available in capacities ranging from 0.2 kN to 10 kN (45 to 2.25K lbf).

I just tried it again. This time without the springs (just a nut over washers). I set my torque wrench for 20 in-lb and repeated torqueing and loosening the nut. Each time the torque wrench clicked.

Last edited:

I think that despite my torque wrench claiming it works down to 20 in-lb IT LIES!!!!

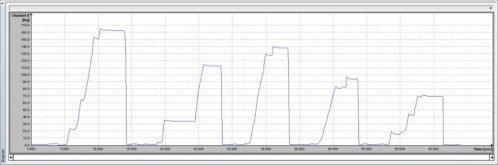

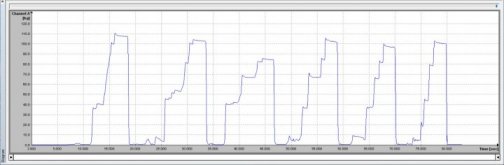

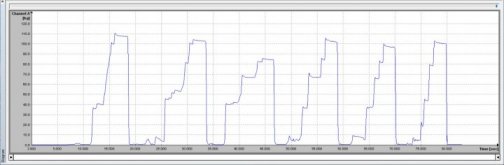

I repeated the test using 40 in-lb and got this. Which is amazingly close to the desired compression force.

That is also the appropriate force we are supposed to torque the bus screws. My head is spinning, what does it mean?

Note to self, don't use my torque wrench at 20 in-lb.

I repeated the test using 40 in-lb and got this. Which is amazingly close to the desired compression force.

That is also the appropriate force we are supposed to torque the bus screws. My head is spinning, what does it mean?

Note to self, don't use my torque wrench at 20 in-lb.

Caution. The above torque/clamping force result is highly conditional (albeit a lot more repeatable than I expected).

- I am using 5/16" x 18 zinc plated carbon steel bolt and nut.

- The only compliance in my test setup is the load cell. If you remove the load cell and just tightened a nut on a bolt the same way you would be likely to get different force. Clamping plywood? No idea.

- My threads are dry, but I have run a nut up and down the bolt many times.

Solarfun4jim

Solar seduced :-)

That is handy info, thanksI think that despite my torque wrench claiming it works down to 20 in-lb IT LIES!!!!

I repeated the test using 40 in-lb and got this. Which is amazingly close to the desired compression force.

View attachment 34642

That is also the appropriate force we are supposed to torque the bus screws. My head is spinning, what does it mean?

Note to self, don't use my torque wrench at 20 in-lb.

I don't know how handy or believable that is. Look at my caution post.That is handy info, thanks

In another thread I implied that the torque we're looking at is so small that the margin for error is large, meaning that A) confidence levels are questionable and B) it doesn't take much to be off. Of course, I was talking about the torque on the terminals, but now I'm thinking the same thoughts may be appropriate for clamping.

Get the compression snug enough that you can lift the battery by the threaded rod with no cells falling out. If a cell falls out, it's too loose.

Get the compression snug enough that you can lift the battery by the threaded rod with no cells falling out. If a cell falls out, it's too loose.

Solarfun4jim

Solar seduced :-)

I have no way of working in Psi. My torque wrench goes down to 1Nm and supposedly accurate to 4%(iirc) (it is the 'click kind' and if you go really slow, the click is clear and positive every time).Caution. The above torque/clamping force result is highly conditional (albeit a lot more repeatable than I expected).

Change any of the above conditions and your result is likely to be different. Possibly very different.

- I am using 5/16" x 18 zinc plated carbon steel bolt and nut.

- There is absolutely no compliance in my test setup (those are thick fender washers and that base is 1/2" thick mild steel).

- My threads are dry, but I have run a nut up and down the bolt many times.

So i was thinking(as an approximation) 300kgf = 29.4Nm divided over 6 rods = 4.9Nm. Now the washers i have on order are 1mm thick, but total height of 1.4mm(giving a deflection of 0.4 mm. The cells expand/contract approx 0.5mm each, so over 8cells in line = 4mm=10washers.

So 10 washers tightened flat to 4.9Nm when at 100% soc, would hopefully be in the ballpark(I'd probably drop back to 4.5Nm for margin of safety). However, presuming at 30%soc, the washers would have 'released' back to close on zero Nm being applied??? Thus i was wondering, and soon to experiment once i recieve my washers, if i doubled them up, could i still manage to torque them to 4.5Nm at 100%SOC and still be left with a reasonable compression at 30% soc. Early days in my thinking, but experimentation should be illuminating.

Clamping something without compliance that is going to expand is like freezing a glass bottle of water that doesn't have any air in it. Enjoy picking the glass shards out of your freezer.In another thread I implied that the torque we're looking at is so small that the margin for error is large, meaning that A) confidence levels are questionable and B) it doesn't take much to be off. Of course, I was talking about the torque on the terminals, but now I'm thinking the same thoughts may be appropriate for clamping.

Get the compression snug enough that you can lift the battery by the threaded rod with no cells falling out. If a cell falls out, it's too loose.

Springs provide both compliance and an easy way to set the preload. Both of which are absolutely required if you intend to do this.

If you ordered enough springs, send me a set and I will see if they are close to being correct. If they can work, I will even measure what preload (turns from finger tight) you should set them to.I have no way of working in Psi. My torque wrench goes down to 1Nm and supposedly accurate to 4%(iirc)

So i was thinking(as an approximation) 300kgf = 29.4Nm divided over 6 rods = 4.9Nm. Now the washers i have on order are 1mm thick, but total height of 1.4mm(giving a deflection of 0.4 mm. The cells expand/contract approx 0.5mm each, so over 8cells in line = 4mm=10washers.

So 10 washers tightened flat to 4.9Nm when at 100% soc, would hopefully be in the ballpark(I'd probably drop back to 4.5Nm for margin of safety). However, presuming at 30%soc, the washers would have 'released' back to close on zero Nm being applied??? Thus i was wondering, and soon to experiment once i recieve my washers, if i doubled them up, could i still manage to torque them to 4.5Nm at 100%SOC and still be left with a reasonable compression at 30% soc. Early days in my thinking, but experimentation should be illuminating.

There is nothing magical about the disc springs I ordered, I ordered a pack of every disc spring in 5/16" ID that McMaster Carr had in stock that had a reasonable working force rating. This particular one works sufficiently well to satisfy me.

If it turns out I need more compliance, I could just add more of the same spring in series, although I think I will probably add some lighter springs to give me a progressive spring rate. I tested that concept when I was looking for 3mm of compliance and was able to find a combination that worked (min pressure was 50 kg, max 94 kg)

Solarfun4jim

Solar seduced :-)

Thanks for the offer HaldorEE, but i think i will be lucky to have 10 spare. The other thing i thought of doing was to attempt to distribute them evenly at either end of the pack....not sure if this would have any influence whatsoever on the compressibility of said spring washers...but i feel better balanced....lol.If you ordered enough springs, send me a set and I will see if they are close to being correct. If they can work, I will even measure what preload (turns from finger tight) you should set them to.

There is nothing magical about the disc springs I ordered, I ordered a pack of every disc spring in 5/16" ID that McMaster Carr had in stock that had a reasonable working force rating. This particular one works sufficiently well to satisfy me.

If it turns out I need more compliance, I could just add more of the same spring in series, although I think I will probably add some lighter springs to give me a progressive spring rate. I tested that concept when I was looking for 3mm of compliance and was able to find a combination that worked (min pressure was 50 kg, max 94 kg)

Everybody, forget PSI. Think what force is the spring going to exert on an individual threaded rod as the cells expand from 0 to 100% SOC.

Assuming you have 4 threaded rods:

Target pressure is 75 kg. This equates to 300 kg total force or 12 PSI

Max pressure is < 108 kg. This equates to 432 kg total force or 17 PSI

Min pressure is > 50 kg. This equates to 200 kg total force or 8 PSI.

If I have to give anything up it is going to be on the minimum pressure. I would not be happy exceeding 100 kg rod force to be honest. My max target is 94 kg.

Assuming you have 4 threaded rods:

Target pressure is 75 kg. This equates to 300 kg total force or 12 PSI

Max pressure is < 108 kg. This equates to 432 kg total force or 17 PSI

Min pressure is > 50 kg. This equates to 200 kg total force or 8 PSI.

If I have to give anything up it is going to be on the minimum pressure. I would not be happy exceeding 100 kg rod force to be honest. My max target is 94 kg.

Solarfun4jim

Solar seduced :-)

I'm six threaded rods, so at least it is distributed more evenly, target pressure of only 50KgEverybody, forget PSI. Think what force is the spring going to exert on an individual threaded rod as the cells expand from 0 to 100% SOC.

Assuming you have 4 threaded rods:

Target pressure is 75 kg. This equates to 300 kg total force or 12 PSI

Max pressure is < 108 kg. This equates to 432 kg total force or 17 PSI

Min pressure is > 50 kg. This equates to 200 kg total force or 8 PSI.

If I have to give anything up it is going to be on the minimum pressure. I would not be happy exceeding 100 kg rod force to be honest. My max target is 94 kg.

ps...i'm not an engineer of any description, so all this is a bit over my head, whilst i fumble my way along.

Last edited:

Solarfun4jim

Solar seduced :-)

Thought this vid was quite interesting...

Solarfun4jim

Solar seduced :-)

Bumping thread back to the top.....

Went with a variation on a theme with regards to using the belville washers.

My washers were spec'ed such that at 60% deflection they were loaded at 243N. At 20% deflection, they were loaded at 117N

The distance between the two 0.24mm.

Thus a single part threaded bolt with 17 washers in series gives:

17 x 243 = 4131N = 17.3psi @ 100% SOC

17 x 117 = 1989N = 8.3psi @ 30% SOC.

Total dist travelled = 17 x 0.24mm = 4.08mm over 8 cells = 0.5mm/cell as per datasheet.

Washers are distributed on a part threaded rod, so no threads to bind the washers movement. Only one cental point of contact, so no uneven pressures applied to one side if a washer got bound up etc. The plate at the cell face is free to move and is held in place only by the force applied by washers.

My intention is never to charge to 100% SOC anyways, so never reaching the 17.3psi maximum. Winter storage at 44% SOC = 30% deflection = 11.43 psi.

Hardest part is final adjustment of the washers at 100% soc, to be very accurately measured.

Seemed like a reasonably good compromise????

Went with a variation on a theme with regards to using the belville washers.

My washers were spec'ed such that at 60% deflection they were loaded at 243N. At 20% deflection, they were loaded at 117N

The distance between the two 0.24mm.

Thus a single part threaded bolt with 17 washers in series gives:

17 x 243 = 4131N = 17.3psi @ 100% SOC

17 x 117 = 1989N = 8.3psi @ 30% SOC.

Total dist travelled = 17 x 0.24mm = 4.08mm over 8 cells = 0.5mm/cell as per datasheet.

Washers are distributed on a part threaded rod, so no threads to bind the washers movement. Only one cental point of contact, so no uneven pressures applied to one side if a washer got bound up etc. The plate at the cell face is free to move and is held in place only by the force applied by washers.

My intention is never to charge to 100% SOC anyways, so never reaching the 17.3psi maximum. Winter storage at 44% SOC = 30% deflection = 11.43 psi.

Hardest part is final adjustment of the washers at 100% soc, to be very accurately measured.

Seemed like a reasonably good compromise????

Very nice. So you’ve used your threaded rods to position a fixed surface against-which the Belleville washers are pushing a calibrated force against an end-plate - I’ve thought about doing the same.Bumping thread back to the top.....

Went with a variation on a theme with regards to using the belville washers.

My washers were spec'ed such that at 60% deflection they were loaded at 243N. At 20% deflection, they were loaded at 117N

The distance between the two 0.24mm.

Thus a single part threaded bolt with 17 washers in series gives:

17 x 243 = 4131N = 17.3psi @ 100% SOC

17 x 117 = 1989N = 8.3psi @ 30% SOC.

Total dist travelled = 17 x 0.24mm = 4.08mm over 8 cells = 0.5mm/cell as per datasheet.

Washers are distributed on a part threaded rod, so no threads to bind the washers movement. Only one cental point of contact, so no uneven pressures applied to one side if a washer got bound up etc. The plate at the cell face is free to move and is held in place only by the force applied by washers.

My intention is never to charge to 100% SOC anyways, so never reaching the 17.3psi maximum. Winter storage at 44% SOC = 30% deflection = 11.43 psi.

Hardest part is final adjustment of the washers at 100% soc, to be very accurately measured.

Seemed like a reasonably good compromise????

View attachment 36428

Here are some things to keep in mind that I hope you’ll be able to confirm soon through your own measurements;

You designed for 0.5mm per cell ‘per datasheet’ but the datasheet indicates nothing by +/-0.5mm on the width, totally unrelated to SOC. This is a total delta of 1.0mm/cell, not 0.5mm.

The one member who has completed a 300Kgf fixture, used it and made measurements reports a 4mm travel between 0% SOC and 100% SOC, so your design should actually be OK (though your travel will be as much as twice that over the first couple of cycles, so I’d advise you to monitor closely and adjust springs as needed, especially to assure you don’t run into the stops and exceed 17psi on the first couple charge cycles.

I like that your using non-threaded rod for your secondary apparatus holding the Belleville washers - that solves one of my biggest issues with them.

I think you have the math wrong though. Force dies not multiply in series, deflection does.

So 17 washers in series will provide you 4.08mm of deflection from a force of 117N to 243N or 26.3lbs to 54.7lbs. This means your single spring is applying 40.5 lbs +/-14.2lbs.

We’re aiming for 660 +/- no more than 330lbs (12psi +/-6psi max).

So you’ll either need a total of 16 springs like the one you’ve built, or you’ll need to use 177 Belleville washers like the one you have in a 4P7S configuration, or you’ll need to get another Belleville washer which applies more force.

Or you can go to Lee Springs and find a single spring you can place on your unthreaded rod that will do the job. At worst you’ll find a spring that means you’ll need to double-up or triple-up the number of pressure points...

Have a look at LHL 200A 04: https://www.leespring.com/compression-springs

609 lbs at solid.

300lbs per inch.

1 of these would give you 11.2 psi @ solid (100% SOC) and 10.3psi after 4mm expansion (0% SOC).

Or with two, you could compress by 2.2” at 50% SOC for exactly 12.1psi and you’d then compress 2mm for 100% SOC @ 12.5psi or decompress 2mm for 0% SOC @ 11.7psi...

There are other options that may be a better fit depending on how much space you have and whether you’re going single-post or double-post, but if I had already invested in the design you have, I’d strongly consider finding a single or doubles compression spring that fit my specs (and budget).

609 lbs at solid.

300lbs per inch.

1 of these would give you 11.2 psi @ solid (100% SOC) and 10.3psi after 4mm expansion (0% SOC).

Or with two, you could compress by 2.2” at 50% SOC for exactly 12.1psi and you’d then compress 2mm for 100% SOC @ 12.5psi or decompress 2mm for 0% SOC @ 11.7psi...

There are other options that may be a better fit depending on how much space you have and whether you’re going single-post or double-post, but if I had already invested in the design you have, I’d strongly consider finding a single or doubles compression spring that fit my specs (and budget).

Solarfun4jim

Solar seduced :-)

Thanks for this...i had assumed that two washers in series, both compressed to 60% would both provide an equal force....back to drawing board....lol.Very nice. So you’ve used your threaded rods to position a fixed surface against-which the Belleville washers are pushing a calibrated force against an end-plate - I’ve thought about doing the same.

Here are some things to keep in mind that I hope you’ll be able to confirm soon through your own measurements;

You designed for 0.5mm per cell ‘per datasheet’ but the datasheet indicates nothing by +/-0.5mm on the width, totally unrelated to SOC. This is a total delta of 1.0mm/cell, not 0.5mm.

The one member who has completed a 300Kgf fixture, used it and made measurements reports a 4mm travel between 0% SOC and 100% SOC, so your design should actually be OK (though your travel will be as much as twice that over the first couple of cycles, so I’d advise you to monitor closely and adjust springs as needed, especially to assure you don’t run into the stops and exceed 17psi on the first couple charge cycles.

I like that your using non-threaded rod for your secondary apparatus holding the Belleville washers - that solves one of my biggest issues with them.

I think you have the math wrong though. Force dies not multiply in series, deflection does.

So 17 washers in series will provide you 4.08mm of deflection from a force of 117N to 243N or 26.3lbs to 54.7lbs. This means your single spring is applying 40.5 lbs +/-14.2lbs.

We’re aiming for 660 +/- no more than 330lbs (12psi +/-6psi max).

So you’ll either need a total of 16 springs like the one you’ve built, or you’ll need to use 177 Belleville washers like the one you have in a 4P7S configuration, or you’ll need to get another Belleville washer which applies more force.

Or you can go to Lee Springs and find a single spring you can place on your unthreaded rod that will do the job. At worst you’ll find a spring that means you’ll need to double-up or triple-up the number of pressure points...

Watching Wills teardown on the SOK and BigBatteries recently I noticed they seemed to have some play in the tolerance between the cells. The batteries appear to be fixed inside by a removable bracket but once that was removed he was able to slide them out pretty easily. I wonder if they can get away with that because they only have a small number of cells inside the pack? Do the larger packs need tighter compression?

I doubt they are compressing at all. At the time those batteries were designed, EVE had not yet even put out any information indicating that compression was beneficial to extended cycle life.Watching Wills teardown on the SOK and BigBatteries recently I noticed they seemed to have some play in the tolerance between the cells. The batteries appear to be fixed inside by a removable bracket but once that was removed he was able to slide them out pretty easily. I wonder if they can get away with that because they only have a small number of cells inside the pack? Do the larger packs need tighter compression?

Those batteries are probably designed so that there is enough space for 100% SOC (possibly with some modest level of compression) and then ~0.5mm of space opens up between cells as they are discharged to 0%.

That’s perfectly fine - it just means those batteries are more likely to deliver the base level of 2500 cycles to 80% capacity versus the new and improved 3500 cycles to 80% capacity (which requires a 300Kgf fixture).

Yeah, 2 washers in series (cone-to-cone) provide double the range for identical force.Thanks for this...i had assumed that two washers in series, both compressed to 60% would both provide an equal force....back to drawing board....lol.

2 washers in parallel (cone-nestled-in-cone) provide double the force over identical range.

It takes 4 washers in series-parallel configuration (parallel pair positioned in series’s meaning outside-cone against outside cone) to deliver twice the force over twice the range...

Solarfun4jim

Solar seduced :-)

Ok, latest incarnation =Have a look at LHL 200A 04: https://www.leespring.com/compression-springs

609 lbs at solid.

300lbs per inch.

1 of these would give you 11.2 psi @ solid (100% SOC) and 10.3psi after 4mm expansion (0% SOC).

Or with two, you could compress by 2.2” at 50% SOC for exactly 12.1psi and you’d then compress 2mm for 100% SOC @ 12.5psi or decompress 2mm for 0% SOC @ 11.7psi...

There are other options that may be a better fit depending on how much space you have and whether you’re going single-post or double-post, but if I had already invested in the design you have, I’d strongly consider finding a single or doubles compression spring that fit my specs (and budget).

A series/parallel stack thus ((()))(((()))((())) x 23pairings.

This equates to 3 x 1181N(3543N) at 75% deflection and 3 x 505N(1515N) at 30% deflection with an overall travel dist of 4.14mm.

I believe this equates to a range of roughly 15psi - 6psi

orrrr...

I might decide just to run three seperate rods/stacks in vertical orientation???

Last edited:

You didn’t indicate the force at 75% deflection, but this will give you 3 times the base force for 3 times the deflection.Ok, latest incarnation =

A series/parallel stack thus ((()))(((()))((())) x 23washers.

This equates to 3 x 1181N(3543N) at 75% deflection and 3 x 505N(1515N) at 30% deflection with an overall travel dist of 4.14mm.

I believe this equates to a range of roughly 15psi - 6psi

orrrr...

I might decide just to run three seperate rods in vertical orientation???

You originally stated that 60% deflection amounted to 243N, so 30% deflection cannot be less than that (and thus cannot be 505N).

3 rods with ((())) each will provide 3 times the force but only 1/3 the range of ((()))((())))((())) but 3 rod with ()( each will give the same force over the same displacement as ((()))((()))((())).

Oh, and 3x3x2 = 28 washers total, not 23...

Similar threads

- Replies

- 23

- Views

- 2K

- Replies

- 0

- Views

- 428

- Replies

- 38

- Views

- 2K

- Replies

- 8

- Views

- 1K

- Replies

- 15

- Views

- 1K

![PXL_20210126_041941673[1].jpg PXL_20210126_041941673[1].jpg](https://diysolarforum.com/data/attachments/34/34638-e7b48bd65a0d0eda2ef16e352ce895a9.jpg)