You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RVs with DIY Lithium

- Thread starter Txglader

- Start date

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

I’m using oxguard. Couldn’t tell you which is “best”.Any suggestions on type of anti-corrosion?

GSXR1000

Solar Enthusiast

- Joined

- Nov 20, 2020

- Messages

- 865

great build... love the use of space...Would love to, but I don't think my current job would allow me the time to do it. It would have to be evenings and weekend, so it would take me a while to complete.

check out my build

Post in thread 'Just ordered Lifepo4 prismatic cell 3.2V 280Ah lithium lifepo4' https://diysolarforum.com/threads/j...-3-2v-280ah-lithium-lifepo4.14955/post-199144

Orderd copper flat bar on eBay and 2 Blue Sea terminals from Amazon. I drilled the flat bar to work with my cable rings.Where did you get your ground bus bar?

I also upgraded the bus bar in the 6 way MEGA holder. older.

Looks great. I had looked at the same box.great build... love the use of space...

check out my build

Post in thread 'Just ordered Lifepo4 prismatic cell 3.2V 280Ah lithium lifepo4' https://diysolarforum.com/threads/j...-3-2v-280ah-lithium-lifepo4.14955/post-199144

Thanks.

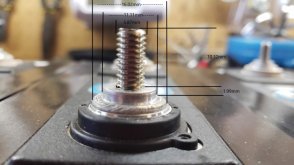

The nuts and washers are stainless. Not sure on the stud itself. The base is aluminum. My neighbor has a machine shop and made me some aluminum washers to go under the bus bars and connect terminals to give a little more surface area. I have seen all kinks of mixed opinions on anti-corrosion so I am not going to use anything at this time and just keep an eye on it.

The aluminum washer around the battery terminal under the bus bars seems like a good idea. With the washer in place there should be more contact area for an electrical connection as you suggest. I have ordered the same Lishen 272ah cell with M6 terminals from Michael. I found some aluminum washers on McMaster-Car that may work after looking at the dimension picture you posted (Thank You).

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

I see nothing wrong with trying without contact grease, but you may want to do a load test first without contact grease and see what happens. The reason I say this is because blutow tried it and had voltage consistency problems with his batteries.

Take a look at his thread on this site and look at the Capacity Test For First Pack message. He list some good lessons learned.

13 kWh Lishen van build

I'm building a battery bank for a new sprinter van I've got coming next month. Original plan was battleborns or SOK's, but I decided to go the DIY route after spending some time on this site. Thanks for the all the great info! The plan is 400watts solar w victron mppt, Victron 12/3000...

I agree there is little consensus on the question of cleaning and contact grease. I will probably clean the terminals with a green scotch brite pad followed by contact cleaner (or 91% isopropyl alcohol) and finally ox-guard. If the battery terminal is not smooth around the M6 stud I will probably first very carefully use a very fine file to make the surface as smooth and flat as possible.

I will also look at the bus bars to make sure they are the same.

It would seem the laser welded M6 stud should also help some with conductivity.

Attachments

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

I would like to continue to see close-ups of your work as you mention and measurements, tooling, EXACT parts numbers and suppliers etc. Thanks in advance!Orderd copper flat bar on eBay and 2 Blue Sea terminals from Amazon. I drilled the flat bar to work with my cable rings.

I also upgraded the bus bar in the 6 way MEGA holder. older.

Thank you for all the info. I just moved the 200lb beast into the camper and starting to wire everything. I plan on testing and keeping an eye on the terminals for heat and voltage loss.The aluminum washer around the battery terminal under the bus bars seems like a good idea. With the washer in place there should be more contact area for an electrical connection as you suggest. I have ordered the same Lishen 272ah cell with M6 terminals from Michael. I found some aluminum washers on McMaster-Car that may work after looking at the dimension picture you posted (Thank You).

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com

I see nothing wrong with trying without contact grease, but you may want to do a load test first without contact grease and see what happens. The reason I say this is because blutow tried it and had voltage consistency problems with his batteries.

Take a look at his thread on this site and look at the Capacity Test For First Pack message. He list some good lessons learned.

13 kWh Lishen van build

I'm building a battery bank for a new sprinter van I've got coming next month. Original plan was battleborns or SOK's, but I decided to go the DIY route after spending some time on this site. Thanks for the all the great info! The plan is 400watts solar w victron mppt, Victron 12/3000...diysolarforum.com

I agree there is little consensus on the question of cleaning and contact grease. I will probably clean the terminals with a green scotch brite pad followed by contact cleaner (or 91% isopropyl alcohol) and finally ox-guard. If the battery terminal is not smooth around the M6 stud I will probably first very carefully use a very fine file to make the surface as smooth and flat as possible.

I will also look at the bus bars to make sure they are the same.

It would seem the laser welded M6 stud should also help some with conductivity.

I have a small wire brush that I cleaned the terminal and washers with.

Thank you for following. I will post more details. Also trying to create a video. Need to download some editing software.I would like to continue to see close-ups of your work as you mention and measurements, tooling, EXACT parts numbers and suppliers etc. Thanks in advance!

GSXR1000

Solar Enthusiast

- Joined

- Nov 20, 2020

- Messages

- 865

if you find a good editing software let me know... thanksThank you for following. I will post more details. Also trying to create a video. Need to download some editing software.

Watched a video a while back on best free video editors. I eill have to see if I can find it again.if you find a good editing software let me know... thanks

All connected, just need to build a false wall now. I am thinking about plexiglass across the top. The MP, MP DC Switch and Watchdog will have cutouts in a thin carpeted wall.

Attachments

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

Man I love that pass-through storage! I'll never be able to repro what you're doing in storage on my Jayco Greyhawk.

Is the bed next to your pass-through? Maybe make a box under the bed that connects to the pass-through?Man I love that pass-through storage! I'll never be able to repro what you're doing in storage on my Jayco Greyhawk.

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

I has no pass-through

But I do have a large side bay that directly connects to under my bed, and this is where I plan to make a shelf and reinforce to support the weight.

The previous owners had a Sleep Number bed and there are already holes anyway in the thin panel for the air tubes.

Under the bed there is no room, I'll just be swapping out the transfer switch located there and doing a 50A upgrade, depending on if I get an AIO etc.

But I do have a large side bay that directly connects to under my bed, and this is where I plan to make a shelf and reinforce to support the weight.

The previous owners had a Sleep Number bed and there are already holes anyway in the thin panel for the air tubes.

Under the bed there is no room, I'll just be swapping out the transfer switch located there and doing a 50A upgrade, depending on if I get an AIO etc.

Attachments

BretS

New Member

- Joined

- Mar 30, 2021

- Messages

- 171

That's awesome! I hope I can get mine to turn out that good! Very similar area to work with in my 5er.All connected, just need to build a false wall now. I am thinking about plexiglass across the top. The MP, MP DC Switch and Watchdog will have cutouts in a thin carpeted wall.

Similar threads

- Replies

- 85

- Views

- 4K

- Replies

- 10

- Views

- 597

- Replies

- 7

- Views

- 218

- Replies

- 14

- Views

- 607

- Replies

- 3

- Views

- 342