OCCOMBILL

New Member

- Joined

- Mar 23, 2021

- Messages

- 3

Thank you, Steve. I guess you already knew that was a perfect resource, since it includes a download to the very batteries I purchased.Download this resource: https://diysolarforum.com/resources/luyuan-tech-basic-lifepo4-guide.151/

That will explain assembly and more.

The BMS's vary depending on manufacturer & type of BMS. The wiring is simple enough, the black is (-) and the rest are the battery sense leads, each one goes onto the appropriate (+) side of each cell. Ring Terminals have to be installed onto the Harness and then attached to the battery BEFORE plugging the harness into the BMS. WARNING, One tiny BooBoo and the BMS goes POOF, it is very sensitive electronics and no margin for error. Best to review the Manual for that specific BMS.

Questions:

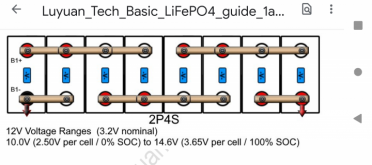

1. I'm building a 2P4S system, and the guide seems to be saying to make the parallel connections first, and also that they should balance naturally. Does this mean that the 4 wires from the BMS are sufficient, since the 4 sets of parallel connected cells should balance naturally?

2. I also see talk of relays, but I'm unclear about why I would need them. Am I correct in assuming that the cheapy BSM simply gets wired in and largely forgotten about, as it does it's balancing in the background?

3. My sketch would have created two 4S packs, linked in parallel, and I see now that would have been wrong! I'll attach a pic from your link that I now believe is correct, for confirmation.

4. My current practice is to put my current boat battery in the trunk of my bike, where it's connected to the bike's battery posts. I believe this acts like "jump starting" for charging purposes, and assume the bike knows better than to overcharge it's own battery. I believe this serves to add to the bike's energy holding capacity, even as running the bike keeps the battery perpetually charged for use in the boat. It seems to work flawlessly, but with a tiny boat battery by comparison. Is there any reason to believe I can't do the same with this new build?

Background that may be relavant: I don't have much discretionary dough, because I'm already dying of Stage 4 colon cancer, suposedly. (Doc gave me 6-18 months, about 3 years ago, and I'm really no closer to dead.) The only reason I bring this up, is because I am unlikely to require the claimed 2,000 charging cycles the seller claimed, so I don't necessarily require an "ideal" build... if there are corners that can reasonably be cut.

More important would be getting it operational, sooner rather than later.

Btw, would a solar company be best to locally source the jumpers between the batteries? The seller included 8, which would be 1 more than I need for 24 volts, but 3 fewer than I need for 2P4S, correct?

Any and all advice will continue to be appreciated!