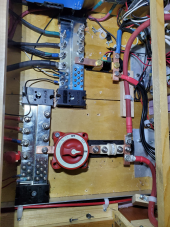

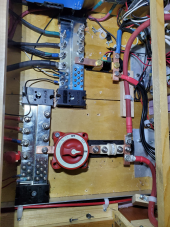

I dont really consider it a problem  I just used calipers to measure the height differences and at some point, I will take the router and machine a pocket in the 3/4" plywood for the battery protects, the fuses will sit on the board and will just cut some blocks on the table saw to insert under the shunt. The top switch will just sit suspended and a block under one end of other switch. Its super simple, just may need a little trial and error to get it perfect.

I just used calipers to measure the height differences and at some point, I will take the router and machine a pocket in the 3/4" plywood for the battery protects, the fuses will sit on the board and will just cut some blocks on the table saw to insert under the shunt. The top switch will just sit suspended and a block under one end of other switch. Its super simple, just may need a little trial and error to get it perfect.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Bus Bars From Copper Flat Bar

- Thread starter HRTKD

- Start date

Paul_R

Solar Enthusiast

BEP solved that problem with their Pro Electrical Installer System.@noenegdod, it looks like you ran into the same problem I have. The mounting surface heights are frequently different. I like the bus bars as shims under the shunt.

I like how closely the copper bus bars allow the devices to be located, but height differences require a bit more effort and materials. I'm going to start with 1/4" plywood. I think I have some 1/8" plywood around here somewhere, but that stuff is kind of worthless.

I was thinking about how to put together strain relief for the cables. I might raid my kids old Lego sets. It doesn't get much more modular than Legos.

Pro Electrical Installer System

That's slick.

The three devices on the positive leg are all Blue Sea Systems. I don't think any of them have the same surface mounting height. At least, not in the order I need them to.

Thank you for posting that! Several months too late for me but it will help someone out for sure!

Which components are you installing?The three devices on the positive leg are all Blue Sea Systems. I don't think any of them have the same surface mounting height. At least, not in the order I need them to.

I thought they were Canadian only but it looks like they are down in the States also:

www.metalsupermarkets.com

www.metalsupermarkets.com

I have no idea if they ship

Store Locator | Find A Store Near You | Metal Supermarkets

Find a Metal Supermarkets store near you with access to over 8,000 metal types, no order minimums, and value-added services.

I have no idea if they ship

Use split point drill bits , they don't walk around and drill easier and less heat . Heat will cause a lot of burrs .

www.mcmaster.com

I have used these for years and they are cheaper than the rest , and drill faster. When Burton Snow Boards first came out in the early 90's , I machined the aluminum angle plate , all of them. I drilled over 54K worth of holes with 1 cobalt screw machine drill bit (@ $1.75 at that time ).

www.mcmaster.com

I have used these for years and they are cheaper than the rest , and drill faster. When Burton Snow Boards first came out in the early 90's , I machined the aluminum angle plate , all of them. I drilled over 54K worth of holes with 1 cobalt screw machine drill bit (@ $1.75 at that time ).

I recommend using a c clamp or vise to hold down the part , because when you break thru, it usually will grab . Using a sacrificial piece of metal (not the drill table) underneath will eliminate the grabbing and less burrs. Use a fresh spot for each hole . I have been at this since 1977.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

I recommend using a c clamp or vise to hold down the part , because when you break thru, it usually will grab . Using a sacrificial piece of metal (not the drill table) underneath will eliminate the grabbing and less burrs. Use a fresh spot for each hole . I have been at this since 1977.

Paul_R

Solar Enthusiast

Any drill bit will wander, some more than others, especially in something as ductile as copper. Center cut end mills, as previously mentioned, are the perfect solution. Failing that, start the hole with a center drill or spot drill. Their whole point is no wandering. Then drill thru with any kind of standard bit.

Added "very sharp"Any drill bit will wander, some more than others, especially in something as ductile as copper. Center cut end mills, as previously mentioned, are the perfect solution. Failing that, start the hole with a center drill or spot drill. Their whole point is no wandering. Then drill thru with any kind of very sharp standard bit.

Most of the people out there do not have a Bridgeport mill to use a 1/4 end mill to drill holes . Drill presses wobble a lot and need a vise. And apparently you haven't used a split point drill bit. I can drill 1/4 holes, 1.5" deep in aluminum at 4000rpm at 100." per min an be within .0005" on size and location with a split point drill and get 50k holes life and still be sharp when i am done with the job at less at a couple for the drill bit.Any drill bit will wander, some more than others, especially in something as ductile as copper. Center cut end mills, as previously mentioned, are the perfect solution. Failing that, start the hole with a center drill or spot drill. Their whole point is no wandering. Then drill thru with any kind of standard bit.

I have been drilling holes in a machine shop for all most half a century.

Paul_R

Solar Enthusiast

It sounds like you're a machinist, I was too in another life long ago ?Most of the people out there do not have a Bridgeport mill to use a 1/4 end mill to drill holes . Drill presses wobble a lot and need a vise. And apparently you haven't used a split point drill bit. I can drill 1/4 holes, 1.5" deep in aluminum at 4000rpm at 100." per min an be within .0005" on size and location with a split point drill and get 50k holes life and still be sharp when i am done with the job at less at a couple for the drill bit.

I have been drilling holes in a machine shop for all most half a century.

For the purpose of this discussion, a center cut end mill will work just fine in a decent drill press and vise. I don't think anybody's after .0005" accuracy. For me it's all about not having to deal with big honking burrs. I may have to go out and buy some split point drills now though...dammit!

Most dont have a bridgeport mill, a continuous supply of coolant or the skills to resharpen split pont drill bits either.Most of the people out there do not have a Bridgeport mill to use a 1/4 end mill to drill holes . Drill presses wobble a lot and need a vise. And apparently you haven't used a split point drill bit. I can drill 1/4 holes, 1.5" deep in aluminum at 4000rpm at 100." per min an be within .0005" on size and location with a split point drill and get 50k holes life and still be sharp when i am done with the job at less at a couple for the drill bit.

I have been drilling holes in a machine shop for all most half a century.

I put masking tape on my 3/16" copper bar stock ---a lot easier to mark my holes for layout -- dimpled with a center punch -- then I made a better center point with an 1/8" bit (not making a hole) -- went directly to 11/32" for my holes --- this particular time I used a Ryobi 12v drill with the bar clamped down on a wood bench --drilled like butter ---- For my first battery I used some 1/4" brass stock I had --Drilled the holes in the same method < but with my drill press ---- the 12v hand drill was much easier -- I'm told brass is harder to drill though

I spent the day at the storage lot yesterday and made good progress. The new step drill bits did a nice job. A quick swipe with sandpaper cleaned up the contact area nicely.

I hauled my drill press and chop saw to the storage lot and that worked out really well, but that drill press is really heavy even though it's a benchtop model.

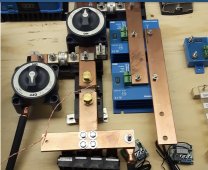

In the picture below, anything that is bright copper is new, the common bus bars (big shiny things) are also new. None of the devices are secured down, covers aren't on and the cable strain relief isn't in place yet either. All this in in preparation of wiring up my new inverter which calls for two cables on each DC leg (pos/neg), four total. I think this new setup is going to be more efficient. I have been stacking cable lugs on posts and I have to wonder if my batteries weren't as well balanced as they could be for charge and discharge. I'm referring mainly to the lugs on the shunt and the Class T fuse.

Some adjustments still need to be made. It's a little rough. I was out of time. It was dark, my flashlight batteries needed a charge and it was 35° F.

I am not impressed with the dinky little M6 studs on the Victron Battery Protect 65.

@noenegdod, the lowest speed on my drill press is 850 rpm. That's higher than I thought.

I hauled my drill press and chop saw to the storage lot and that worked out really well, but that drill press is really heavy even though it's a benchtop model.

In the picture below, anything that is bright copper is new, the common bus bars (big shiny things) are also new. None of the devices are secured down, covers aren't on and the cable strain relief isn't in place yet either. All this in in preparation of wiring up my new inverter which calls for two cables on each DC leg (pos/neg), four total. I think this new setup is going to be more efficient. I have been stacking cable lugs on posts and I have to wonder if my batteries weren't as well balanced as they could be for charge and discharge. I'm referring mainly to the lugs on the shunt and the Class T fuse.

Some adjustments still need to be made. It's a little rough. I was out of time. It was dark, my flashlight batteries needed a charge and it was 35° F.

I am not impressed with the dinky little M6 studs on the Victron Battery Protect 65.

@noenegdod, the lowest speed on my drill press is 850 rpm. That's higher than I thought.

Bluedog225

Solar Wizard

Wow. That’s nice. (Last pic)I drill copper by hand with an electric drill starting with a mechanical center punch.

View attachment 79307

Next is a 5/32"drill bit for pilot holes. All my drill bits are good quality 118° split point. I'll use any cutting oil that's around.

Step drilling 1/6" at a time keeps bits from getting plugged and breaking.

If the bar has hard wood/plastic (ViseGrip) clamped to it I'll drill thorough if not I stop 1/2 way and come in from the other side but that doesn't work as wall as the backing.

A counter sink removes the burr and make the bars look pro.

Most important is keeping the drill perpendicular to the surface.

That Diablo blade looks like it has a positive (a line along the face of the tooth crosses in front of the center hole) rake. A true non ferrous blade has a zero or a negative rake like this one has. Also note the backing for the teeth is shorter and much stronger.

View attachment 79309

***Be very very very careful cutting copper with a saw blade. I've seen people screw up and rip 10-15 teeth off a blade along with the backing for the teeth. I've also seen the motor come off the rails on compound saws. Cut through the smallest dimension. Make sure it is double/tripple clamped.

I like to used the lesser of 2 evils which is a Walter 1/16" zip cut wheel on a grinder but the copper gets scorching hot. I've seen people that don't know how to use a zip wheel destroy it by side loading or twisting it and have piecs of the disc embed in a wall 20' away.

This is the proper position to for a grinder when zip cutting. Most important is to always have it pulling away from you an

View attachment 79299

Last edited:

That looks good!I spent the day at the storage lot yesterday and made good progress. The new step drill bits did a nice job. A quick swipe with sandpaper cleaned up the contact area nicely.

I hauled my drill press and chop saw to the storage lot and that worked out really well, but that drill press is really heavy even though it's a benchtop model.

In the picture below, anything that is bright copper is new, the common bus bars (big shiny things) are also new. None of the devices are secured down, covers aren't on and the cable strain relief isn't in place yet either. All this in in preparation of wiring up my new inverter which calls for two cables on each DC leg (pos/neg), four total. I think this new setup is going to be more efficient. I have been stacking cable lugs on posts and I have to wonder if my batteries weren't as well balanced as they could be for charge and discharge. I'm referring mainly to the lugs on the shunt and the Class T fuse.

Some adjustments still need to be made. It's a little rough. I was out of time. It was dark, my flashlight batteries needed a charge and it was 35° F.

I am not impressed with the dinky little M6 studs on the Victron Battery Protect 65.

@noenegdod, the lowest speed on my drill press is 850 rpm. That's higher than I thought.

View attachment 81069

I found that the step drills seem to do a good job of cleaning up burs like a counter sink does.

850 RPM is still a pretty good clip. Im impressed you are able to do such a good job. Slowest speed on mine is 280 (max 3000) and I drill everything copper at that speed now. Just have to be super careful with small dia bits as they tend to grab and break.

Does your drill press have an idler pulley or just a primary and secondary? Mine has an idler and 2 belts which might be why it is so much slower.

That looks good!

I found that the step drills seem to do a good job of cleaning up burs like a counter sink does.

850 RPM is still a pretty good clip. Im impressed you are able to do such a good job. Slowest speed on mine is 280 (max 3000) and I drill everything copper at that speed now. Just have to be super careful with small dia bits as they tend to grab and break.

Does your drill press have an idler pulley or just a primary and secondary? Mine has an idler and 2 belts which might be why it is so much slower.

It was dark and perhaps I didn't have the right reading/safety glasses on. 820 turned out to be 620 once I got a look at it in daylight.

No idler pully. Just the primary pulley on the motor and the secondary on the spindle. It's a 25 year old Delta benchtop model that I've had since it was new. I checked to make sure the table was square to the bit in two directions and it was right on the money.

The Dish Doc

Photon Pharmer

Sanding around each of your bolt holes is probably a good idea for connectivity. I don't know about that flat bar but I know copper pipe has a "clear coat" on it to prevent it from turning green. I built a copper fountain for my KOI pond thinking it would turn a nice green patina but the coating stopped that until sanded off. One of my only youtube videos LOL.

Sanding around each of your bolt holes is probably a good idea for connectivity. I don't know about that flat bar but I know copper pipe has a "clear coat" on it to prevent it from turning green. I built a copper fountain for my KOI pond thinking it would turn a nice green patina but the coating stopped that until sanded off. One of my only youtube videos LOL.

If there is a clear coat on the flat bar, it's certainly gone after I dress the contact surface with sandpaper. I had considered treating the bus bars once there were in place with a quick spray of polyurethane to deter oxidation. But I'm going to let it go for now and see how it ages.

Bluedog225

Solar Wizard

My understanding of that picture is that every bus bar you see there is the same polarity, it's all positive.

I’m curious about the arc interruption capacity of the air gap between bus bars. Some of those look pretty close.

If/when a moth lands and bridges the gap, I wonder if there could be a problem? That is, how much space between bus bars would be needed at a given voltage?View attachment 82327

I had the same concern and asked that question here: https://diysolarforum.com/threads/how-close-can-bare-copper-bus-bars-be-12v.30555/

Not so much about a moth but if the battery protects were to open while the winches that are down stream from the battery protects were operating, would 12v jump that gap. Just to be clear, the two bars that are really close are both positive. That thread exposed a few other issues I had and was able to work out a solution that should address all the issues.

I am also thinking about greasing up the bars and the battery protect and extruding some silicone between them to absolutely prevent any chance of any kind of unwanted current between the two bars.

Similar threads

- Replies

- 14

- Views

- 362

- Replies

- 5

- Views

- 507

- Replies

- 7

- Views

- 192