Topics covered or touched upon for those that have better things to do than read long posts:

Extensive testing with the following hardware and configurations:

Conext SW 4048 and XW Pro running older and the most recent firmware.

XW Pro AC coupling via Enphase Microinverters (well not real extensive in this area)

Using 10 and up to 18 - 400w panels in both AC with Enphase IQ7+ micoinverters and DC string modes

AC and DC coupling at the same time with the Pro. (awesome)

Two types of battery packs - 48vdc battery pack composed of 4 generic FLA deep cycle, and another 280ah cells, 16s, Eve LFP (LifePO4)

Conext Battery Monitor (why it's needed for LFP or in a complex Hybrid system)

How to burn up the above battery monitor like I did

Both Export and zero export in all testing

Using the Gateway rather than the Combox with Insight local (you better have three or four display monitors)

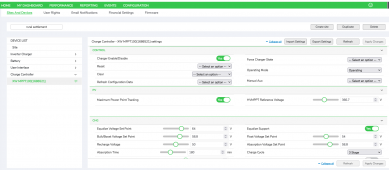

Note: I'm no expert. I have a lot of solar equipment with many different types of batteries, inverters, and things to run tests with. I have more hours to work on this than most and I'm going to figure out the details so I can sell LifePO4 based solar storage batteries. I use the Configuration Tool but in most cases it's really not needed. Nice for backing up each devices configuration though and restoring or copying it to another device.

I have been testing the SW 4048 and the XW Pro in a split phase 120/240 scenario. Both were tested with AC coupling with 10 to 15 400w panels running Enphase IQ 7+ microinverters. I initially started using a Combox and a SCP. Later I added the battery monitor and in the beginning I was using 4 generic FLA 12v deep cycle 80ah batteries. Initially I was not impressed with the battery monitor for the price. The main unit weighs about 2 or three ounces when the cables are not hooked to it. Around that same time I added a Conext MPPT 60 150 into the AC coupled system.

Understanding the real relationship the battery monitor has with the batteries, the inverter, and the charge controller was a little of a challenge (actually huge one). I also tested this in a full AC coupling whereas I connected the incoming microinverters to my critical loads panel. This is where Schneider really shines. I will clarify this a little more.

One test I ran was with all of the following:

a. Conext Mppt 60 150 connected to 4 - 400w panels 2 groups of 2 in is series and then I paralleled them together. (2P - 2S) Tied to my batteries.

b. 10 - 400 watt panels using Enphase IQ7+ microinverters programmed to export to the grid.

c. 4 - 12vdc generic deep cycle batteries tied to the XW Pro

d. The interesting twist - AC coupling of 4 - 400w panels running Enphase IQ7+ microinverters in which I had the XW Pro set not to export.

e.

The results from my perspective were spectacular but I only ran the system for a few days while I sat right next to it monitoring it the whole time. The battery monitor in a system like that is almost a critical component. Why? Because it's voltage reading directly from the batteries is deadly accurate and it sends the info to both the charge controller and to the inverter. I have found so far with all three Conext inverters I have used that they do not read VDC accurately. They can easily be so much as .6v off at any moment and that is not acceptable in a hybrid system.

With external meters I monitored every voltage point for variations. Yes, cables, connectors, shunts, circuit breakers, especially current, and everything else in a system like this causes deviations in voltage. Without a Battery Monitor you can almost pull your hair out trying to get your inverter and MPPT charge controller to sync correctly. Using the Battery monitor for SOC can be very helpful but I have found it can be dangerous with LFP batteries in some conditions. If everything is perfect, it works great but you better have countless hours to make everything work and make sure that BMS never loses power because it will default to 75% SOC on a dead or fully charged battery and it will report that to all of your other hardware.

Currently I'm doing extensive testing on the XP Pro with 16 - 280ah Eve cells and I just burned up my Conext Battery Monitor after connecting it just beyond my Daly 250a BMS. BTW, impressive BMS with UART for BT and USB to serial adapter. That has been a lifesaver when LFP cells start to run. But the Conext battery monitor got turned off and back on multiple times by the Daly BMS because I did not have the Conext battery monitor directly on the battery. I had connected it a little farther down the line. Don't do that.

The XW Pro I have is always .4 to .6vdc off compared to actual readings at the battery and at the terminals of the inverter itself. Considering you have less than three volts to work with on a 16s LFP pack set for 80% DOD that inaccuracy is not acceptable. The Battery manager will fix that and I have not found anything else that will other than working countless hours programming your charge cycles until you find a happy medium.

XP Pro has the ability with the most recent firmware to disable SOC while using the Battery Monitor. In the past I was never able to do that. This allows you to setup the charging parameters by voltage rather than SOC. It is said that the XW will always refer to voltage over SOC but my testing has not shown that to be true. I could be wrong but I have seen the XW over charge batteries based upon SOC and not voltage.

Cons of the Conext Battery Manager:

Difficult to press the buttons sometimes

Small display

Setting the function areas that have to be configured through it's control panel (very antiquated)

No external power input for backup. Will run off Xanbus and will run off the battery it's connected to (or so I remember)

Disconnect the battery and power for more than a couple minutes and it will dump all SOC current conditions and then reset to 75%

Very little of it's configuration can be done through the Gateway.

Battery mid point testing is not applicable in many cases.

It has no per cell monitoring as such for any battery chemistry or configuration (yes there are some exceptions)

The way it needs to be mounted does not fit into any normal design. It's interface box is 3" or more deep requiring cutting a hole if you want some form of surface mount.

It's very expensive

Learning curve can be range from minutes to months.

Pro:

It's what you need for complex designs if you want full integration between most Schneider solar based systems. Having a battery reference voltage that is shared throughout your Xanbus network allows for extreme programming configuration in charge and discharge cycles for both AC and DC based coupling and more so with Hybrid configurations.

Very accurate battery voltage and current readings.

Current readings from the shunt can be matched and or reset so that you don't have devices showing random small amounts of current that don't exist.

Warning

For those of you like me that started working with this stuff from scratch you can possibly cook your Combox, Gateway, and especially your Battery Monitor and even your SCP if you make this almost fatal (to the equipment) mistake. I have not figured out all the details yet, and you will get away with this mistake for a few times but it will catch up with you if you are using a Conext Battery Manager and are not aware of it.

All of the devices above use Xanbus among other protocols as well but Xanbus has 12vdc power. So in the process of connecting and disconnecting those devices it is possible you may power up your inverter or your charge controller from one of them. We all know what happens with powering up an inverter or charge controller without using a resistor, or a combination of resistors, diodes, and/or caps, or at least something that reduces that momentary arc while connecting.

The Conext battery monitor when first connected to your batteries will arc severely if your inverter is not on. Why, it will power up your inverter through what I feel is the Xanbus connection meaning very fragile parts are exposed to very high amperage surge. Multiple times I have had this happen and then I added in circuit breakers and didn't see the flash any longer which I feel caused the early EOL for the battery manager.

Looking forward to learning more on this incredible forum. Thanks Will for inspiring the world to acknowledge LifePO4's answer to solar storage for the average DIY guy and providing us this forum to share our experiences.

I would really appreciate some input on how not to cook a Battery Monitor. I have used resistors and that does stop the arcing when connecting the positive or negative power wires to the battery terminals.