I am planning to put up 6 panels in my backyard. Was thinking of making some type of metal frame to support the panels. I am wondering are there already made kits? If not, where do people typically buy such material. Homedepot and lowes have some channels and brackets, but I am not sure if that is the easiest or best way to go about it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ground Array. Where to buy material

- Thread starter chumanji9

- Start date

Bluedog225

Texas

Kits are pretty expensive.

Diy wood is cheapest and can last a long time if pressure treated for ground contact and hot-dipped galvanized fasteners used.

Unistrut aka superstrut is a good option but requires some study to do it correctly. And somewhat expensive.

Lots of sample arrays on youtube etc.

and welcome!

Diy wood is cheapest and can last a long time if pressure treated for ground contact and hot-dipped galvanized fasteners used.

Unistrut aka superstrut is a good option but requires some study to do it correctly. And somewhat expensive.

Lots of sample arrays on youtube etc.

and welcome!

wiseacre

Solar Addict

Adjustable DIY wood mount

panels are set in pairs with the frame pivoting on a bolt through the 4x4 uprights

Eco Worthy mount kit (you'll need two or more)

https://www.eco-worthy.com/collecti...nting-brackets-for-1-4-pieces-of-solar-panels

panels are set in pairs with the frame pivoting on a bolt through the 4x4 uprights

Eco Worthy mount kit (you'll need two or more)

https://www.eco-worthy.com/collecti...nting-brackets-for-1-4-pieces-of-solar-panels

Bluedog225

Texas

Wood is high right now. Way high.

Strut can often be found on craigslist for half the price of home depot. Wood as well.

Bed frames (the metal base part) can be used to build a cheap metal frame if you are handy.

Strut can often be found on craigslist for half the price of home depot. Wood as well.

Bed frames (the metal base part) can be used to build a cheap metal frame if you are handy.

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

I have 20,640 watts at 45 degree angle on a 30 degree slope, 48 ea 4 x 4 pt post, 34 ea uni-struts. A lot of 2x4 bracing. Treated botom 24" of each post with termite poison, dried, then painted with black synthetic rubber, dried, set post in two to three 80 lb bags of quikcrete. It works fine. Cost around $4K. 2 months hard labor after work and on weekends. Manual post hole diggers. Stainless Steel 3/8"x 2.5" bolts/large belleville washers.

Last edited:

Any name you wish

New Member

I have 6 panels also. The previous post is likely what I'll build too. Right now I'm just propping them up at an angle on the lawn to measure effective combinations because I have a mixed setup.

Here's my advice. Search craigslist or facebook marketplace for people giving away old metal bed frames. Even if not free, they're typically under 20 bucks a set. It's some strong solid hard steel angle pieces that are about 5-6' long. Since I taught myself welding for 2020, I've been using that as a base material for many projects. You could drill and bolt as an alternative.

Here's my advice. Search craigslist or facebook marketplace for people giving away old metal bed frames. Even if not free, they're typically under 20 bucks a set. It's some strong solid hard steel angle pieces that are about 5-6' long. Since I taught myself welding for 2020, I've been using that as a base material for many projects. You could drill and bolt as an alternative.

Bluedog225

Texas

Sounds good. Pics would be great.I have 20,640 watts on 48 ea 4 x 4 pt post, 34 ea uni-struts. Treated botom 24" of each post with termite poison, dried, then painted with black synthetic rubber, dried, set post in two to three bags of quikcrete. It works fine.

MichaelK

Solar Wizard

I went with schedule-40 pipe and standard unistruts. I got the pipe at a local fencing company. Specified the lengths of the 3.5" and 4.0" pipes, and they cut it for me on the spot.

The unistruts were a combination of HomeDepot superstruts, and random sellers on Craigslist. Craigslist was far more economical then HD.

The unistruts were a combination of HomeDepot superstruts, and random sellers on Craigslist. Craigslist was far more economical then HD.

StuartV

New Member

Bluedog225

Texas

I was seriously thinking about something along these lines. I’d want something to tie the panel to the post. Maybe heavy wire.

Super ghetto, cheap, and simple.

Any name you wish

New Member

So here is how they are mounted:I was seriously thinking about something along these lines. I’d want something to tie the panel to the post. Maybe heavy wire.

Super ghetto, cheap, and simple.

Nylock nuts. The metal at the top is the clips that you use for mirrors so I can adjust the height up or down as needed. The poles come with little clips for fencing so I bent it out a little more and they fit nice in some of the holes on these panels for rain. All panel poles have metal hose clamps holding them to the pole next to them. Light duty posts. two 4 ft. ones and two 6 ft. ones. Everything drove at least 1 ft. into the ground. Posts for reference: https://www.acehardware.com/departments/building-supplies/gates-and-fences/fence-posts/72509

Side view:

There are already holes in each post so no drilling required.

Bluedog225

Texas

Thanks for the pics. That has a lot of appeal. Maybe the best, cheapest, long-life, mounts I’ve seen.

I was getting hung up on wanting to find a way for the post not to poke out past the panel. Maybe some shadow but I don’t know how much shadow is significant.

I was getting hung up on wanting to find a way for the post not to poke out past the panel. Maybe some shadow but I don’t know how much shadow is significant.

Any name you wish

New Member

Use shorter bolts than I did. That was me not doing a great measurement. I did show it to a couple buddies of mine and shook the entire array. Barely moved and everything was solid. I have one panel in that set that is not the same size so I had to adjust post position. Otherwise everything is staying put. Once I get the storage in a better place, I can double production pretty easy.Thanks for the pics. That has a lot of appeal. Maybe the best, cheapest, long-life, mounts I’ve seen.

I was getting hung up on wanting to find a way for the post not to poke out past the panel. Maybe some shadow but I don’t know how much shadow is significant.

OffGridInTheCity

Solar Wizard

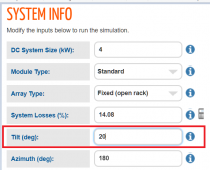

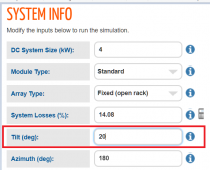

Another issue is angle. I worried about this - probably too much - as I didn't really understand the impact of the choices.

Suggest using PVWatts - https://pvwatts.nrel.gov/pvwatts.php - for your location with the defaults and just play with Tilt (deg) to see the different kwh estimates based on the different angles.

You may want to optimize for winter or summer or in-between or make it changeable. The angle may worry you more or less - but at least you can put some actual numbers to the design choice you settle on

Suggest using PVWatts - https://pvwatts.nrel.gov/pvwatts.php - for your location with the defaults and just play with Tilt (deg) to see the different kwh estimates based on the different angles.

You may want to optimize for winter or summer or in-between or make it changeable. The angle may worry you more or less - but at least you can put some actual numbers to the design choice you settle on

peakbagger

Solar Enthusiast

- Joined

- Oct 26, 2021

- Messages

- 323

ncsolarelectric

Engineering Support CEO

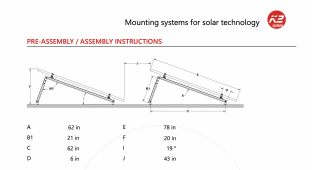

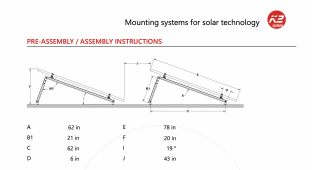

Tamarack Solar has several inexpensive ground mount component kits. They give you all the fittings and clamps, but you need to source the Schedule 40 galvanized pipe. Unirac, IronRidge, and K2, all have pre-engineered ground mounts with plans you can download for permits.

Honestly, they are practically the same price as wood and a lot less labor, IMO. Either way, if you are buying lumber capable of withstanding 110 mph winds, as I have in my backyard, I estimated the cost of using wood for 10 panels to be between $100 - $150 per solar panel. I used the big 400W, 72/144 Cell panels. I haven't found a way to do it cheaper, except ballasted flat-roof/ground mount with a 5 to 10 deg tilt. It's a cheap and easy DIY project. I did this one myself. I just needed help moving the panels in place because they're longer than I am tall. Just remember to put down the weed barrier "first".

You can also build a floating deck and use an attached tilt-up system by K2. You can hide the ballast blocks under the deck and it doesn't even require footings. In NC, if it's less than 30" tall, and not attached to the house the deck doesn't require a building permit.

One more idea I had. Use metal roofing panels and build a galvanized, or aluminum metal roof on the ground. Attach a tilt-up system like K2 using S-5! Clamps to clamp onto the standing seam, or just bolt the L-foot to the metal roofing. Then stack ballast blocks and gravel to cover up the metal. It'll look good!

Honestly, they are practically the same price as wood and a lot less labor, IMO. Either way, if you are buying lumber capable of withstanding 110 mph winds, as I have in my backyard, I estimated the cost of using wood for 10 panels to be between $100 - $150 per solar panel. I used the big 400W, 72/144 Cell panels. I haven't found a way to do it cheaper, except ballasted flat-roof/ground mount with a 5 to 10 deg tilt. It's a cheap and easy DIY project. I did this one myself. I just needed help moving the panels in place because they're longer than I am tall. Just remember to put down the weed barrier "first".

You can also build a floating deck and use an attached tilt-up system by K2. You can hide the ballast blocks under the deck and it doesn't even require footings. In NC, if it's less than 30" tall, and not attached to the house the deck doesn't require a building permit.

One more idea I had. Use metal roofing panels and build a galvanized, or aluminum metal roof on the ground. Attach a tilt-up system like K2 using S-5! Clamps to clamp onto the standing seam, or just bolt the L-foot to the metal roofing. Then stack ballast blocks and gravel to cover up the metal. It'll look good!

Last edited:

ghostwriter66

"Here - Hold my Beer"

Put the panels in PORTRAIT and use PVC pipe -- we do that all the time when we are in a hurry ... we prop the bottom of the panel off the ground on top of a cinder block ... and then use PVC pipe to make a triangle frame for the sides to get it to the right angle -- or close enough ... at this time of year hell just laying them out on the ground works great ... ....

peakbagger

Solar Enthusiast

- Joined

- Oct 26, 2021

- Messages

- 323

If you are in high wind area you need to tie them down to keep them from being lifted up and thrown by the wind. My pole mount was designed for a high wind zone. The hihgest wind speed in North America was recorded about five miles south of my place. No guarantees my pole mount would survive 231 MPH but it has been through some high surface winds.

Bluedog225

Texas

Nicely done! I have wondered if strut could take the weight. Looks like it has no issues.Unistrut works well.

BTW, it this is permitted installation the AHJ may require an engineered system.

View attachment 101824

Have you priced steel lately? Went to a local metal supplier to get square tube for a pole mount ... 2"x2"x1/16"thin wall square tubing @20' is $83. Nope, it can wait. Housing is diving and the price of lumber is starting to come down. Doubt it will ever get back to the prices it was a couple years ago. For that matter, doubtful anything will get back to the price it was just over a year ago.Wood is high right now. Way high.

Strut can often be found on craigslist for half the price of home depot. Wood as well.

Bed frames (the metal base part) can be used to build a cheap metal frame if you are handy.

peakbagger

Solar Enthusiast

- Joined

- Oct 26, 2021

- Messages

- 323

Note the doubled and triple depth strut. It will take the weight but it will deflect quite bit unless doubled or tripled up.Nicely done! I have wondered if strut could take the weight. Looks like it has no issues.

MichaelK

Solar Wizard

ncsolarelectric

Engineering Support CEO

This is a nice one! I would do this if I could dig holes and mix concrete. I like this design. Ironridge also has a nice tilt-up system. You just need something to screw it down to. He used 4x4's and it looks great. I bet it could easily handle 120 mph winds.Tamarack Solar has several inexpensive ground mount component kits. They give you all the fittings and clamps, but you need to source the Schedule 40 galvanized pipe. Unirac, IronRidge, and K2, all have pre-engineered ground mounts with plans you can download for permits.

Honestly, they are practically the same price as wood and a lot less labor, IMO. Either way, if you are buying lumber capable of withstanding 110 mph winds, as I have in my backyard, I estimated the cost of using wood for 10 panels to be between $100 - $150 per solar panel. I used the big 400W, 72/144 Cell panels. I haven't found a way to do it cheaper, except ballasted flat-roof/ground mount with a 5 to 10 deg tilt. It's a cheap and easy DIY project. I did this one myself. I just needed help moving the panels in place because they're longer than I am tall. Just remember to put down the weed barrier "first".

You can also build a floating deck and use an attached tilt-up system by K2. You can hide the ballast blocks under the deck and it doesn't even require footings. In NC, if it's less than 30" tall, and not attached to the house the deck doesn't require a building permit.

One more idea I had. Use metal roofing panels and build a galvanized, or aluminum metal roof on the ground. Attach a tilt-up system like K2 using S-5! Clamps to clamp onto the standing seam, or just bolt the L-foot to the metal roofing. Then stack ballast blocks and gravel to cover up the metal. It'll look good!

View attachment 101838

Similar threads

- Replies

- 3

- Views

- 220

- Replies

- 0

- Views

- 95

- Replies

- 2

- Views

- 276

- Replies

- 48

- Views

- 1K