You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compress or not, flexible busbar or not

- Thread starter Cheap 4-life

- Start date

MrM1

I'm Here, But I'm Not All There

Same.I have watched all Andy's videos, but I wasn't convinced no compression was the correct way to go, so I compressed with foam and used flexible busbars.

I compressed with plastic sheets and made up flexible busbars from lugs and cable.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

Compression will not stop bloating. Only causes bulge on sides and/or increased cell pressure. Popping the vent port is worst result.

Root cause is electrolyte break down. Overvoltage, high cell current, or high temp is most common cause of electrolyte breakdown. Less than 0.1v cell voltage will also cause bloating but that is not so common.

In Andy's case I would suspect high temp or high discharge current. The different age and condition of three banks can result in over current discharge on one of the strings. Needs to pay more attention to total current distribution between the three strings. Getting above 0.5 C(A) on a given string is a red flag.

Root cause is electrolyte break down. Overvoltage, high cell current, or high temp is most common cause of electrolyte breakdown. Less than 0.1v cell voltage will also cause bloating but that is not so common.

In Andy's case I would suspect high temp or high discharge current. The different age and condition of three banks can result in over current discharge on one of the strings. Needs to pay more attention to total current distribution between the three strings. Getting above 0.5 C(A) on a given string is a red flag.

Last edited:

MrM1

I'm Here, But I'm Not All There

Seemed to like the right place / time as it was referenced in this thread.I was wondering when that video would come up.?

MrM1

I'm Here, But I'm Not All There

I hope Andy gets it sorted out for himselfCompression will not stop bloating. Only causes bulge on sides and/or increased cell pressure. Popping the vent port is worst result.

Root cause is electrolyte break down. Overvoltage, high cell current, or high temp is cause of electrolyte breakdown.

MrM1

I'm Here, But I'm Not All There

I'm not saying, compression right or wrong. I don't know anything.Back on page 1 of this thread, Andy from the Off Grid Garage YouTube channel was referenced as saying why he would not compress. I wonder if Andy is having 2nd thoughts?

It was just interesting that a video at the top of this thread was referenced, and the same video creator came back a year + later with findings

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

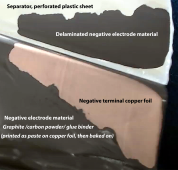

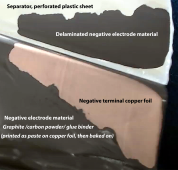

Compression is good if you subject cell to high current. The object of compression is to minimized delamination of electrode material from their graphite negative electrode copper current colllector foil or LFP electrode to aluminum current collector foil.

Below 0.5 C(A) cell current, compression yields little benefit.

When electrolyte decomposes it causes dried out hydrocarbon tar gummy areas that increases stress on separator sticking to electrode causing pulling on electrode causing delamination. In the picture if there is fluid electrolyte permeating porous separator there would be no reason for graphite to stick to separator. This cell has been subjected to overcharging, overcurrent, or over temperature that resulted in electrolyte decomposing to dry, sticky, hydrocarbon tars that stuck graphite electrode to separator.

The electrolyte decompostion gas, mostly CO2 and CO, produces gas that bloat the metal container. It is not the most damaging affect, it is the other hydrocarbon tars created and left behind in the laminate.

Below 0.5 C(A) cell current, compression yields little benefit.

When electrolyte decomposes it causes dried out hydrocarbon tar gummy areas that increases stress on separator sticking to electrode causing pulling on electrode causing delamination. In the picture if there is fluid electrolyte permeating porous separator there would be no reason for graphite to stick to separator. This cell has been subjected to overcharging, overcurrent, or over temperature that resulted in electrolyte decomposing to dry, sticky, hydrocarbon tars that stuck graphite electrode to separator.

The electrolyte decompostion gas, mostly CO2 and CO, produces gas that bloat the metal container. It is not the most damaging affect, it is the other hydrocarbon tars created and left behind in the laminate.

Last edited:

I think Andy’s cells will be fine as long as he gives them space to get the tension off of the terminals like he did on the top shelf. From what I’ve read, compression of swollen cells is a bad idea. His cells are mildly swollen and probably not an issue. I have and still will continue to compress with a centralized spring of a known spring rate. Time will be the true tell.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

I agree, the bloating is not that bad.I think Andy’s cells will be fine as long as he gives them space to get the tension off of the terminals like he did on the top shelf. From what I’ve read, compression of swollen cells is a bad idea. His cells are mildly swollen and probably not an issue. I have and still will continue to compress with a centralized spring of a known spring rate. Time will be the true tell.

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

This.. i compressed because mistakes happen. Bms malfunctions and because manufacturers said the cells will have more cycles so why not, it’s easy to compress them.Compression is good if you subject cell to high current. The object of compression is to minimized delamination of electrode material from their graphite negative electrode copper current colllector foil or LFP electrode to aluminum current collector foil.

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

Compression will not stop bloating. Only causes bulge on sides and/or increased cell pressure

This is kinda conflicting but I get what you mean. However since compression can minimize delamination, doesn’t compression do that by stopping expansion? bloating and expansion being differentCompression is good if you subject cell to high current. The object of compression is to minimized delamination

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

My objection to compression is many DIY'er do a non compliant fixed dimensional compression that results in an exponential increase in pressure at full charge or higher ambient temperatures.

You can crack electrodes or crush separator causing a cell short if too much compression is applied. The spec list 300 kgf across cell surface which is 29 lbs per square inch which is high risk if not carefully controlled. The separator, preventing a cell short, is only a very thin, porous polypropylene plastic sheet.

If you want cell longevity don't run them above 0.5 C(A). Above 0.5 C(A) the cell internal temp cycling increases due to internal cell heating that stresses electrode lamination. At 0.5 C(A) maximum current there is low internal cell heating and cell compression has little benefit.

You have to weigh the risk versus benefit.

You can crack electrodes or crush separator causing a cell short if too much compression is applied. The spec list 300 kgf across cell surface which is 29 lbs per square inch which is high risk if not carefully controlled. The separator, preventing a cell short, is only a very thin, porous polypropylene plastic sheet.

If you want cell longevity don't run them above 0.5 C(A). Above 0.5 C(A) the cell internal temp cycling increases due to internal cell heating that stresses electrode lamination. At 0.5 C(A) maximum current there is low internal cell heating and cell compression has little benefit.

You have to weigh the risk versus benefit.

Last edited:

MrM1

I'm Here, But I'm Not All There

Do you differentiate between true cell compression and what would be more of a fixture frame that presses the cells together for mobile and RV applications. Or would those b essentially 1 in the same from a design, concept and execution point of view.My objection to compression is many DIY'er do a non compliant fixed dimensional compression that results in an exponential increase in pressure at full charge or higher ambient temperatures.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

You need some sponge or spring compliance to keep pressure uniform over some dimensional expansion and contraction.Do you differentiate between true cell compression and what would be more of a fixture frame that presses the cells together for mobile and RV applications. Or would those b essentially 1 in the same from a design, concept and execution point of view.

A few threaded metal rods to end plates is a hard fixed dimensional compression that can exponentially increase compression pressure when cells expand.

The surface of cells is not uniformly flat so a hard flat surface can create high pressure points. A compliant rubber pad between cells helps to even irregularities in cell surface.

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

Exactly why I decided to use springsMy objection to compression is many DIY'er do a non compliant fixed dimensional compression that results in an exponential increase in pressure at full charge or higher ambient temperatures.

Ron-ski

Solar Enthusiast

This was my only concern with they way I did it. I have 2 rows of 8 cells , with 1mm PCB sheets between each cell. At either end of a row is 1/4 Poron foam, which is compressed using 10mm aluminium plates and studs/bolted tubes. I would have preferred foam between each cell but just couldn't buy the correct foam.The surface of cells is not uniformly flat so a hard flat surface can create high pressure points. A compliant rubber pad between cells helps to even irregularities in cell surface

My second battery should be online at the end of the month, even with one battery I don't go near 0.5c even though I could. The most I've seen flowing in is around 100A with 280ah cells. Once the second battery is in, I'll charge at 140A, so 0.25C for each battery, solar charging will be less.

MrM1

I'm Here, But I'm Not All There

What is a good source for the foam? (links ) What is it called?

Ron-ski

Solar Enthusiast

This is the one I used https://www.mcmaster.com/86375K234/What is a good source for the foam? (links ) What is it called?

Read this thread, although there are a lot of posts.

My biggest concern was when one cell was nearly flat and the next had a slight bulge(less than 1/16) and could violate the flat plane of the other. All the batteries I’ve seen have two vertical bulges where the “jelly rolls” reside so there will be two pressure points regardless. I fitted Formica sheets between each cell to help mitigate protrusion from another and provide insulation. I tried to find the fiberglass sheets like you see in the kits and they were too expensive. The ends are doubled up glued 3/4 ply. Even with 500lbs each row of eight have moved the pusher plate 3/16 and move very little through the cycle now. Basically, they have moved what they’re going to after 16 months.

I’d love to see what the close fitting rack cells look like after a year with welded busses and nowhere near an expansion force strength structure. Do really want to even look? It may give you an idea what the cells can actually take as far distortion and stress.

I’d love to see what the close fitting rack cells look like after a year with welded busses and nowhere near an expansion force strength structure. Do really want to even look? It may give you an idea what the cells can actually take as far distortion and stress.

MrM1

I'm Here, But I'm Not All There

I wonder if 3mm EVA foam sheets could be used? Probably not dense enough.This is the one I used https://www.mcmaster.com/86375K234/

Read this thread, although there are a lot of posts.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 20

- Views

- 536

- Replies

- 23

- Views

- 1K