You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please help mpp LV2424 not charging

- Thread starter Hunter937

- Start date

MichaelK

Solar Wizard

Did you boot up the unit on battery power only at startup? Most stand-alone charge controllers get confused if you apply the solar voltage before battery voltage. Is this stand-alone unit designed to work without a battery? If you think it is the settings that are problematic, then what are the settings?

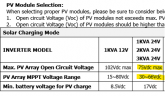

Thanks for your reply, It is powered by 4 100ah 12v lithium ion batteries. I originally booted it off of the batteries. And my settings are as followsDid you boot up the unit on battery power only at startup? Most stand-alone charge controllers get confused if you apply the solar voltage before battery voltage. Is this stand-alone unit designed to work without a battery? If you think it is the settings that are problematic, then what are the settings?

Attachments

NoSmokeYet

New Member

- Joined

- Apr 14, 2020

- Messages

- 49

MisterSandals

Participation Medalist

Can you describe your array setup?

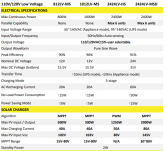

This is my array set upCan you describe your array setup?

Attachments

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

Looks like NoSmokeYet is correct, since 80V exceeds the max 75V shown in data sheet.

Certainly inconvenient that the data sheet shows 12V system allows 102Voc but the 24V system only allows 75Voc. And 30V minimum for MPPT operation. That isn't as wide a window.

Please post all specs for your PV panels. There should be one for volts per degree too, giving how output varies with temperature.

If you presently have 4 panels in series, change that to three. So long as these are 12V nominal panels, based on data for some I have, three in series should stay in the right voltage range.

If you presently have 2, 24V panels in series you can try just one panel. It may drop below 30V MPPT on a hot day so won't deliver maximum power.

Certainly inconvenient that the data sheet shows 12V system allows 102Voc but the 24V system only allows 75Voc. And 30V minimum for MPPT operation. That isn't as wide a window.

Please post all specs for your PV panels. There should be one for volts per degree too, giving how output varies with temperature.

If you presently have 4 panels in series, change that to three. So long as these are 12V nominal panels, based on data for some I have, three in series should stay in the right voltage range.

If you presently have 2, 24V panels in series you can try just one panel. It may drop below 30V MPPT on a hot day so won't deliver maximum power.

MichaelK

Solar Wizard

To me, this really looks like a lemon of a product. 75Voc seems absurd to me. Even lower budget controllers are at least 100V, and the better ones are 150V. Assuming those are 12V panels, with a Voc around 21, and a Vmp around 18, you might try either a 2S4P or a 3S2P configuration. The problem with going 2S4P is that the Vmp is going to be barely 36V, and that might not be high enough for the MPPT controller to work properly. The problem with 3S2P is you only get to use 6 of your panels instead of 8. What might work for you is to find one more panel of the same specs and wire them into a 3S3P configuration. Before going out and buying anything though what I would first suggest is to just try wiring two panels in series and give it a test, then add a third panel in series, and see what happens?

Newbie question... If the Max PV Input Voc is 145V, while the other chart says 75Vdc... what exactly is the difference between Voc and Vdc ? I thought series connecting 3 24v panels was ok with this 24v All-in-One unit? Could parallel connect... has anyone asked the sellers on this?

MisterSandals

Participation Medalist

Voc is the open circuit voltage (the no load max voltage a panel will produce under standardized conditions 25 deg c being one of the conditions).If the Max PV Input Voc is 145V, while the other chart says 75Vdc... what exactly is the difference between Voc and Vdc

I think "75Vdc" is just implying "75 volts direct current", more of a general specification.

This is a wildly vague specification. Some "24v panels" have a Voc over 45v.connecting 3 24v panels

If you want to have a meaningful panel voltage limits discussion, Voc has to be the number used.

Well, the ones I'm currently looking at are Voc = 40V to 40.9V... so if that is a normal range for mono 24v panels, would 3 of them in series work with this 24v All-in-One? It seems that the original post on this thread has had a problem, no?

MisterSandals

Participation Medalist

There is no normal for “24v panels” which is why we ask - to get the math right.Voc = 40V

MisterSandals

Participation Medalist

3 in series is 120v which exceeds the critical(?) 75v limit in one of your spec pics.would 3 of them in series work with this 24v All-in-One? It seems that the original post on this thread has had a problem, no?

Even 2 in series exceeds that limit.

The SCC appears to be an unfortunately poor match for those panels.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

We need exact model numbers of both panel and charge controller, and links to data sheets, to do a good job analyzing it.

There is a temperature coefficient which could push the 3 series panels above even the 145V spec of one inverter shown above. Two in series may work for some of the inverters and one inverter looks like even a single "24V" panel could charge a 24V battery.

There is a temperature coefficient which could push the 3 series panels above even the 145V spec of one inverter shown above. Two in series may work for some of the inverters and one inverter looks like even a single "24V" panel could charge a 24V battery.

This isn't my thread/spec pics... so I don't want to intrude on "Hunter 937"s question about his unit. I'm ordering the 3KVA unit and it's PV array MPPT Voltage Range is 30~115 Vdc... so it seems 3 in series at Voc 40V and VMP 32.6V would be ok for me... no? It does seem Hunter's problem is the MPPT Voltage Range limitation on his unit... if I understand it correctly, no?

MisterSandals

Participation Medalist

You need to use max input voltage not the mppt range.PV array MPPT Voltage Range is 30~115 Vdc

But 3x 40 is not good for anything over 110v max input volts considering temp increase as temp drops below 25 deg C., by the panels’ temp coefficient.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

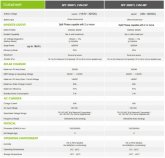

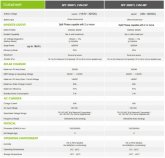

Is your "3KVA" unit one of these?

I see 2.4kW, 24V battery, 145V max, 30 to 115V mpp, or 3.2 kW, 48V battery, 145V max, 60 to 115V mpp.

I would worry about three of your 40Voc panels in series going well over 120V, approaching 145V on a cold bright day. It might never happen, but you should design the system so it can never get damaged by those conditions. (I don't know how much safety margin it really has over that. The brand I have logs highest voltage ever experienced for purposes of voiding the warranty.)

If yours is the 30 to 115V mpp model, two panels in series should be fine. If 60 to 115V mpp, on a hot day it may clip at 60V and deliver a bit less power due to not reaching mpp of the panels.

Exact model numbers and data sheets for your inverter and panels, and historical high/low temperatures for your location, and we can do better.

I see 2.4kW, 24V battery, 145V max, 30 to 115V mpp, or 3.2 kW, 48V battery, 145V max, 60 to 115V mpp.

I would worry about three of your 40Voc panels in series going well over 120V, approaching 145V on a cold bright day. It might never happen, but you should design the system so it can never get damaged by those conditions. (I don't know how much safety margin it really has over that. The brand I have logs highest voltage ever experienced for purposes of voiding the warranty.)

If yours is the 30 to 115V mpp model, two panels in series should be fine. If 60 to 115V mpp, on a hot day it may clip at 60V and deliver a bit less power due to not reaching mpp of the panels.

Exact model numbers and data sheets for your inverter and panels, and historical high/low temperatures for your location, and we can do better.

Not sure about Hunter above, but for me, my location will soon change from Midwest to moderate temps anywhere.. chasing fair weather.. and the unit I am getting is the Growatt 24v :

Ships Mid June 24V 3kW Growatt SPF LVM 120V/240V solar Inverter Split Phase optn | eBay

I was going to get some used 24v panels from Santan if they have any that fit the 60 cell pattern for the roof of the van... 3 would fit otherwise new ones like the one below. Most of these seem to share similar Voc etc. I was thinking I could series connect them, but are you thinking that isn't possible? Would I have the same problem Hunter might be having above with panels exceeding the MPPT range? even if only a little and in ideal conditions, right?

Ships Mid June 24V 3kW Growatt SPF LVM 120V/240V solar Inverter Split Phase optn | eBay

I was going to get some used 24v panels from Santan if they have any that fit the 60 cell pattern for the roof of the van... 3 would fit otherwise new ones like the one below. Most of these seem to share similar Voc etc. I was thinking I could series connect them, but are you thinking that isn't possible? Would I have the same problem Hunter might be having above with panels exceeding the MPPT range? even if only a little and in ideal conditions, right?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

"Good temperature coefficient ..." it says, but this page doesn't tell us what it is.

Let's assume -0.4% per degree C. Consider -15 C vs. 25 C ambient, 40% colder. Voc would be 16% higher, 40 Voc @ ambient --> 46.4 Voc @ -15C.

3 series panels x 46.4 = 139.2 Voc, probably safe with 145V max Voc for inverter.

3 x 40 = 120 Voc at ambient, above the 30 - 115V mpp, might not start at least until they get hot. Cold day, the MPPT may never start.

2 series panels x 40 = 80 Voc, no problem starting

2 x 32.6 = 65.2 Vmpp, middle of the MPPT range. Any plausible temperature will be fine, hot or cold.

You can realistically get about 70% to 80% of the 310W STC rating of the panel, so 8 panels 2s4p all oriented one direction would max out at about 2000W. You could parallel more strings with some oriented differently to flatten production over the day and the seasons. On a van so limited area. You could hinge or slide some out as an awning to fit more, secure against the wind. Make a tilt mount for what's on the roof unless you plan to be near the equator.

Let's assume -0.4% per degree C. Consider -15 C vs. 25 C ambient, 40% colder. Voc would be 16% higher, 40 Voc @ ambient --> 46.4 Voc @ -15C.

3 series panels x 46.4 = 139.2 Voc, probably safe with 145V max Voc for inverter.

3 x 40 = 120 Voc at ambient, above the 30 - 115V mpp, might not start at least until they get hot. Cold day, the MPPT may never start.

2 series panels x 40 = 80 Voc, no problem starting

2 x 32.6 = 65.2 Vmpp, middle of the MPPT range. Any plausible temperature will be fine, hot or cold.

You can realistically get about 70% to 80% of the 310W STC rating of the panel, so 8 panels 2s4p all oriented one direction would max out at about 2000W. You could parallel more strings with some oriented differently to flatten production over the day and the seasons. On a van so limited area. You could hinge or slide some out as an awning to fit more, secure against the wind. Make a tilt mount for what's on the roof unless you plan to be near the equator.

I was planning to put a tilt ability for the panels on the van's roof. What is the difference between the Voc and the Vmp? As for the max Voc potential, you're saying I shouldn't put all 3 in series, but only 2, leaving one in parallel to avoid any potential overage on the MPPT which is limited to 115v... correct?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

I was planning to put a tilt ability for the panels on the van's roof. What is the difference between the Voc and the Vmp? As for the max Voc potential, you're saying I shouldn't put all 3 in series, but only 2, leaving one in parallel to avoid any potential overage on the MPPT which is limited to 115v... correct?

Correct regarding only 2 in series. Avoid having Voc exceed top end of charge controller's MPPT range or it may not start operating. Definitely avoid exceeding maximum voltage spec to prevent damage.

But, don't do 2 in series, paralleled with 1. That'll pull down the 2 series string to about Voc of the 1, and force excessive current into the 1. You should use 4 panels in 2s2p configuration. Or 3 panels 1s3p if voltage would still be high enough. Or use a different charge controller with high enough voltage ratings for 3s1p.

I have suggested an MC-4 "Y" cable with fuses as an alternative to combiner box, but two many strings could exceed current capability of the wire. I've seen 4 or 5 input "Y" cables. Some panels are 4 amp and others are 7 amp. 7 x 4 = 28A is a bit too much for either a 10 AWG wire unfused or for a 30A fuse suitable for that wire. Fuses should be at least 25% higher than the peak PV Isc under all temperature and illumination conditions. I forget just how much oversize a wire should be to use unfused, probably at least 50%.

Voc, shown on the label and data sheet, is the voltage you would see with a volt meter on the wires, with open circuit (no current being drawn), panel at 25 degrees C, illumination of one standard sun (1000 W/m^2 and the spectrum we get from sun directly overhead.)

Your actual Volts Open Circuit could be higher on a cold day, or with direct sun on the panel plus light bouncing off nearby clouds.

Isc is the short circuit current you get with an ammeter across the leads (voltage pulled to zero by the meter) and same temperature and illumination conditions.

Your actual current short circuit could be higher, so don't want to use too small a fuse, and if no fuse the wires need to be suitably oversized.

Vmp and Imp are the particular voltage and current with a load ideally sized such that power = Vmp x Imp are maximum. Again under standard temperature and illumination.

Your actual power will typically be lower because panels get warmed in the sun. Sometimes higher on a cold day. The label specs are "STC" for standard test conditions. You may also see specs for "PTC", which are realistic performance test conditions of elevated temperature and a slight breeze that carries heat away.

This link suggests PTC could be 10% to 15% less than STC:

Solar Panel Efficiency — Understanding STC and PTC Ratings | IWS

Are you comparing solar panel options? Efficiency — the panels’ ability to convert sunlight into energy — is a feature you should consider.

You also have losses due to wiring IR drop and inverter efficiency. I had a system with Sharp polycrystaline panels that appear to have delivered AC power 84% of PTC ratings, and that with an inverter in the 92% to 95% range. Another with Astropower monocrystaline only performed that well initially, then dropped to about 70% of PTC.

So, 3 in parallel, making one series = 1s3p, correct? Otherwise, get a different solar charge controller than the one that comes with the All-in-One, a unit with a higher top end range like 150Vdc? But to utilize the 3K 24v All-in-One, I should just parallel the 3 panels? Is the problem you mention about voltage being high enough a reference to the low end of the MPPT voltage range of 30Vdc? Wouldn't that mean less potential in low light conditions etc? Tilt would help, but only to a degree of local sunlight conditions, right? So, like Hunter 937's original question for this thread, it's a question of working with the limitations of these All-in-Ones, if you choose to use them?

I was questioning the issue of wiring the panels parallel vs in series... as I might be seeing a lot of shading in the areas I'm in... not sure how much time will be spent in shaded vs full sunlight exposed areas. But to play it safe with this All-on-One, parallel connection is the answer?

I was questioning the issue of wiring the panels parallel vs in series... as I might be seeing a lot of shading in the areas I'm in... not sure how much time will be spent in shaded vs full sunlight exposed areas. But to play it safe with this All-on-One, parallel connection is the answer?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,788

Yes, all 3 in parallel would be 1s3p. But with full sun, those 24V panels would be at he low end of 30 to 115V MPPT range, and hot day or shading or sun at an angle would reduce output, maybe stop producing.

I think 2sNp is best, where "N" = 1,2,3

If you can really only fit 3 panels, not 4, you might get away with using a switch to choose 2 or 3 in series. Rather than interrupting the path to insert the 3rd one, you could string all three in series and use a "Y" connector on both sides of one panel and use a suitable switch to short out one if the 115V upper end is exceeded. On a hot day that won't happen, and even on a cold day as soon as the charge controller starts drawing current you could switch the third back in and it'll stay below 115V until current tapers to zero.

I think 2sNp is best, where "N" = 1,2,3

If you can really only fit 3 panels, not 4, you might get away with using a switch to choose 2 or 3 in series. Rather than interrupting the path to insert the 3rd one, you could string all three in series and use a "Y" connector on both sides of one panel and use a suitable switch to short out one if the 115V upper end is exceeded. On a hot day that won't happen, and even on a cold day as soon as the charge controller starts drawing current you could switch the third back in and it'll stay below 115V until current tapers to zero.

Similar threads

- Replies

- 19

- Views

- 732

- Replies

- 1

- Views

- 100

- Replies

- 6

- Views

- 687

- Replies

- 38

- Views

- 2K

- Replies

- 7

- Views

- 390