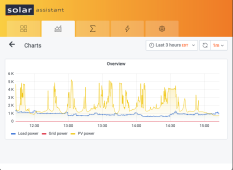

WOW .. You have provided another GREAT Idea.,

@fmeili1 for the win again!

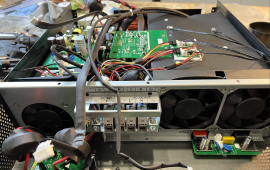

So what I am going to try is to 3d print a 4 inch duct adapter for my intake 120mm Fan(in Air conditioned room), and run duct(s) to the two Intake locations on the EG4.

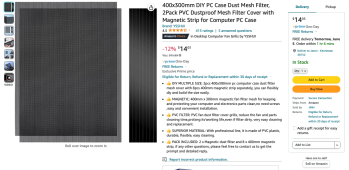

The challenge will be to custom make a Filter Plate/Duct intake coupler . This way the EG4 will bring in Air conditioned air...

I thinik this might just work!

When you say you are 3d printing custom duct adapters, What exactly are you printing ?... are you indeed printing the adapter that attaches to the EG4 intake too ?.... if so , can you share your design / CAR file? Thanks in advance!..... Getting closer and closer..

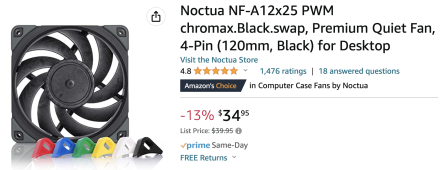

BTW: I bought two Noctua fans(

NF-A12x25 PWM chromax.Black.swap) for the Intake vent to the closet .. These are EXTREMELY Quiet!

~RandomPlanet