Aridom82

Learning addict

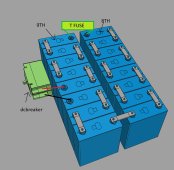

While i am learning more and more i come up with new questions. In a 16 cell 48v lifepo4 battery build, what hardware would you think is best for protection?

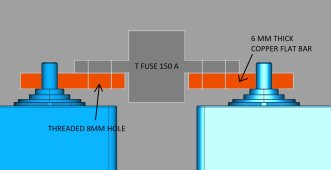

Right now i am putting just a 160 amp dc breaker. Could a class T fuse in combination with a simple battery disconnect switch be better?

Right now i am putting just a 160 amp dc breaker. Could a class T fuse in combination with a simple battery disconnect switch be better?