I’m connecting a 12/1200 Phoenix inverter and after much research I’m still unsure of what fuse/wire size to use with this. The terminals only allow for a max of 25mm size cable which translates to 4awg. This seems to small of a gauge for a 1200 watt inverter that could pull 100amps. 4awg handles a max of 85amps or so depending on insulation rating. Using to general 1.25 multiplier I should be using a 150amp fuse. So 4awg doesn’t come close to 100amp let alone 150amp capacity. The inverter only has a 125amp internal fuse. So what am I missing here? Seems the inverter undersized the input terminals substantially. So based on the 85amp rating of 4awg I should be using around a 110amp fuse or so and hope I don’t draw to much???

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

12/1200 Phoenix Inverter Confusion

- Thread starter WyoSoular

- Start date

mikefitz

Solar Wizard

- Joined

- May 28, 2020

- Messages

- 3,015

Automotive 25mm2 cable available in the UK is rated up to 170 amps. 4 AWG is csa 21mm2.

It's possible to use pin type compression terminals is overcome this type of limitation you are experiencing, metric example.

atpconsumables.co.uk

atpconsumables.co.uk

It's possible to use pin type compression terminals is overcome this type of limitation you are experiencing, metric example.

Heavy Duty Copper Tube Pins

Competitive Pricing Free Delivery On Orders Over £50 UK Certified Products Next Day Delivery On Selected Products Bulk Pricing/Delivery Options If you can't find what your looking for on our website, or would prefer to speak to a member of our team regarding an order, we are more than happy...

atpconsumables.co.uk

atpconsumables.co.uk

Strange that ampacity rating are widely different for the same wire size. So yes 4awg is 21mm but 3awg is 26mm so 4awg is max if using the wire only. Those connectors you show theoretically could carry more current at the tip since they’re solid. But why would Victron undersized the terminals? Seems we’re missing something here.

Bluedog225

Texas

- Joined

- Nov 18, 2019

- Messages

- 3,029

Following. And I recall victron wants you to use bare wire, not ferrules.

Q-Dog

¯\_(ツ)_/¯

According to the manual, the 12 volt version should be able to fit 35mm2 / 2 AWG. The 24 and 48 volt version have the 25mm2 / 4 AWG connections.

OzSolar

Whatever you did, that's what you planned.

Ironically just yesterday afternoon I was running 4 AWG at 100 amps on my new Victron 450/100 charge controller for several hours. Took some scans with my thermal camera and the hottest I saw was 95 degrees f. That was ambient plus 50. I don't have any concerns with my installation.

The Blue Seas calculator returns 6 AWG for the first set of variables I chose. 12v, 3', 5% voltage drop, 5mins

3' 3% and 60 minutes was 4AWG.

The Blue Seas calculator returns 6 AWG for the first set of variables I chose. 12v, 3', 5% voltage drop, 5mins

3' 3% and 60 minutes was 4AWG.

Bluedog225

Texas

- Joined

- Nov 18, 2019

- Messages

- 3,029

Nice wizard. Thanks!

Q-Dog

¯\_(ツ)_/¯

Victron also strongly advises to use fine strand cable for connections. I don't have their manual in front of me now, but I do know from past experience, fine strand cable wire has the most surface contact when compressed into their clamping style terminals.

Please note....VICTRON does not rate their inverter in WATTS......the rating is VA.....Volt Amps. For AC Volt Amps includes reactive amps which is NOT POWER.....THAT IS REFLECTED POWER..A direct result of VOLTS and AMPS NOT IN PHASE

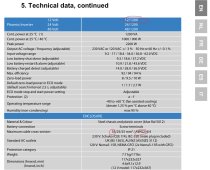

Read the specs....very clearly it is RATED 1000 watts for a short time and 900 watts continuous

Pump up the numbers, sell more on an assumption

No other reputable inverter manufacturer uses Volt-Amps

True watts is the STANDARD OF THE INDUSTRY...

Read the specs....very clearly it is RATED 1000 watts for a short time and 900 watts continuous

Pump up the numbers, sell more on an assumption

No other reputable inverter manufacturer uses Volt-Amps

True watts is the STANDARD OF THE INDUSTRY...

Ahhhhh ok I see now I read the wrong terminal size. So 2 awg has a range of 75-100 depending on insulation rating and heat etc.. so if the actual unit only puts out 900 continuous watts as someone stated above that would be a 100amp fuse needed and using 2awg is marginal at best?

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,311

I have seen Victron recommend finely stranded wire for their bigger SCCs, 100 amps and up, but have not seen a recommendation for strand size or ferrules for their other products.

I have a Phoenix 375 VA which is the same manual as the 1200 VA inverter and there is no recommendation for strand size or whether or not to use ferrules in that.

With lack of manufacturer recommendation, I’d go with an industry standard or best practice. Please keep in mind our best practices are all over the spectrum and an industry standard is a bit more difficult to locate than “how to secure a wire in an inverter,” since strand size, connector type all play into effect.

I have a Phoenix 375 VA which is the same manual as the 1200 VA inverter and there is no recommendation for strand size or whether or not to use ferrules in that.

With lack of manufacturer recommendation, I’d go with an industry standard or best practice. Please keep in mind our best practices are all over the spectrum and an industry standard is a bit more difficult to locate than “how to secure a wire in an inverter,” since strand size, connector type all play into effect.

So essentially Wong it after doing extensive research and viewing conflicting information?I have seen Victron recommend finely stranded wire for their bigger SCCs, 100 amps and up, but have not seen a recommendation for strand size or ferrules for their other products.

I have a Phoenix 375 VA which is the same manual as the 1200 VA inverter and there is no recommendation for strand size or whether or not to use ferrules in that.

With lack of manufacturer recommendation, I’d go with an industry standard or best practice. Please keep in mind our best practices are all over the spectrum and an industry standard is a bit more difficult to locate than “how to secure a wire in an inverter,” since strand size, connector type all play into effect.

Q-Dog

¯\_(ツ)_/¯

Why do you think 2awg is "marginal?" Are you using more than 20 total feet of wire from battery to inverter? Use this chart and good wire.Ahhhhh ok I see now I read the wrong terminal size. So 2 awg has a range of 75-100 depending on insulation rating and heat etc.. so if the actual unit only puts out 900 continuous watts as someone stated above that would be a 100amp fuse needed and using 2awg is marginal at best?

Part 1: Choosing the Correct Wire Size for a DC Circuit - Blue Sea Systems

Engineering high quality marine electrical components for safety, reliability and performance

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,311

You can say wing it if you want.So essentially Wong it after doing extensive research and viewing conflicting information?

You could also say make the best choice after receiving as much data as you could.

I can see advantages to using finely stranded wire and also square ferrules for the Phoenix inverter installation. I also think it you have already installed a 12 strand wire, it will work in most instances and you do not need to do rewiring unless this is an inverter that runs all out all the time.

Seems like if the build is fixed like a house, the smaller wire like 10 AWG tends to be solid core copper, which I believe is the only acceptable code, but mobile installations use stranded wire, perhaps because the wires could vibrate loose.

At some point you need to make a decision.

Similar threads

- Replies

- 0

- Views

- 182

- Replies

- 11

- Views

- 2K

- Replies

- 4

- Views

- 383

- Replies

- 19

- Views

- 1K

- Replies

- 11

- Views

- 612