Have you decided yet how to handle the MC4 connectors?

View attachment 77454

I never did like the way MPP has them coming directly out the bottom like that. I did buy a 6-ft wide trough to put under my LV6548s, and I'm gonna do conduit runs same like you.

However, I don't like the idea of using the MPP's MC4 connectors and having raw cable-runs run right into the bottom of the inverter, it just doesn't look as clean as the Sol-Ark installs for example (where all runs can be inside conduits).

Like I'd rather have all-conduit runs for cleanest, professional look (I'm an old car stereo installer guy from the 90's, I also like to do clean installs and rather go all the way, or none of the way, if I'm going to go through the trouble, it should look clean, and no raw cables hanging out).

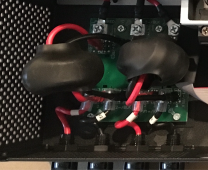

I was thinking of either remounting the MC4s inside the box, having a single smaller diameter conduit going into the case, or removing the MC4 connectors altogether, and installing terminal blocks inside the MPP case.

Or just putting a big fat conduit that is large enough to go around all four of the MC4 connectors (not screwed on, just butted up flush against bottom of case). That would make it a lot more tricky to get the MC4 connectors apart later, working inside of a large conduit coming up from the bottom of the trough/box... Or making the fat conduit, slidable with some set screws, so it is more a cosmetic thing where you can loosen set screws on the bottom and slide it down to get the MC4 connectors apart if needed.

I am leaning towards just removing the MC4 connectors. Other idea is to soldier in longer pigtails inside the MPP case and extend the longer wires down to the trough/box below, and put PV terminal connection blocks down there where there is more room.

What did you have in mind? Or are you not going to worry about that and just connect your raw PV cable runs right to the factory connectors and not have conduit there?