Monument Mountain Man

New Member

- Joined

- Mar 30, 2022

- Messages

- 12

Greetings,

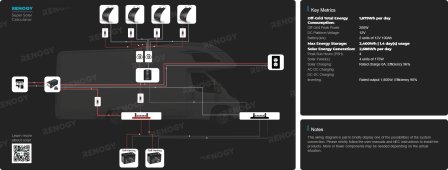

I am new to this, but think I have a good design. I am curious if I missed something or over/under designed something.

I have a Thor Vegas that came “Solar ready”, which gave me a Go Power 10 amp Charge Controller (this one will be removed), with 10 gauge wiring to the rooftop connection ports. Note the 10 gauge wire… I know there are several options for panels, charge controllers… but I thought for my first design I would stick with a single vendor for most items. Hoping that means easy integrations and installation, then trouble shooting…

I am going to use (4) Renogy 175 watt flexible panels. Each panel’s positive connection will have an inline 15 amp fuse at the panel. The cables will then go into the Renogy 4 to 1 Solar Branch Connectors that will connect to the existing roof top connection port with the 10 gauge wire. No issues with this panel design going into 10 gauge wire on the way down to the charge controller, right??

In the rig, the wires will come into the new Renogy’s Rover 60 Amp MPPT Solar Charge Controller, with bluetooth option. The positive outbound side to the battery bank will have a fuse on it, but not sure what size to use. Renogy suggested 75 Amp, which from other posts and my searching, I understand is not a common size. I have found a 70 and 80 on Amazon. Should I just use a 70 here?

The battery bank is (2) Renogy LiFePO4 12-volt 100Ah lithium batteries with self healing functions, with the monitor that connects to the batteries. No shunt required to monitor them.

I am using the Renogy 2000W 12V Pure Sine Wave Inverter. I am using 4AWG cable with a fuse on the positive line. Renogy support suggested a 230 Amp fuse here. I am still looking, but I found 200 and 250. Any suggestions here??

I will do a DC to DC connection in the future, nice review by Will Prowse.

Thanks for any comments on this design.

I am new to this, but think I have a good design. I am curious if I missed something or over/under designed something.

I have a Thor Vegas that came “Solar ready”, which gave me a Go Power 10 amp Charge Controller (this one will be removed), with 10 gauge wiring to the rooftop connection ports. Note the 10 gauge wire… I know there are several options for panels, charge controllers… but I thought for my first design I would stick with a single vendor for most items. Hoping that means easy integrations and installation, then trouble shooting…

I am going to use (4) Renogy 175 watt flexible panels. Each panel’s positive connection will have an inline 15 amp fuse at the panel. The cables will then go into the Renogy 4 to 1 Solar Branch Connectors that will connect to the existing roof top connection port with the 10 gauge wire. No issues with this panel design going into 10 gauge wire on the way down to the charge controller, right??

In the rig, the wires will come into the new Renogy’s Rover 60 Amp MPPT Solar Charge Controller, with bluetooth option. The positive outbound side to the battery bank will have a fuse on it, but not sure what size to use. Renogy suggested 75 Amp, which from other posts and my searching, I understand is not a common size. I have found a 70 and 80 on Amazon. Should I just use a 70 here?

The battery bank is (2) Renogy LiFePO4 12-volt 100Ah lithium batteries with self healing functions, with the monitor that connects to the batteries. No shunt required to monitor them.

I am using the Renogy 2000W 12V Pure Sine Wave Inverter. I am using 4AWG cable with a fuse on the positive line. Renogy support suggested a 230 Amp fuse here. I am still looking, but I found 200 and 250. Any suggestions here??

I will do a DC to DC connection in the future, nice review by Will Prowse.

Thanks for any comments on this design.