Good evening everyone! I’m back with a new project lol. So in my never ending quest to be as self sufficient as possible I am working towards building a wood shop to process wood from my little sawmill.

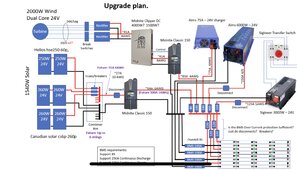

Here’s where my problem lies. This shop isn’t going to be an everyday use shop, at least not the large power draw tools anyway. I have a solar system that one of the wonderful members here helped me get designed properly (thank you FilterGuy !) and with the addition of some used solar panels we have been cruising along in the house perfectly with 0 generator usage.

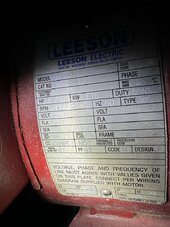

Okay. So my dilemma, one of the first tools I have purchased for this shop is a woodmaster 718 helical planer, it’s a beast of a machine, with an equally beastly electric requirement. In operation it uses up to 5 electric motors. The main planer drive is a farm duty 5hp motor, then a 5hp dust collector, 2-3.5hp routers and a 1/8hp feed motor. My aimes 6000 watt 18,000 surge inverter definitely was not a fan of the 5hp motor (be nice I know I’m a dummy for even trying, I didn’t realize motors can draw up to 5x rated amps on startup) and now I’m at a dilemma. I think my only option is a pto powered generator for my tractor (38.3 hp at the pto) to run something like this at home. I do have the option of a shop in town with grid power but then I have to transport all my wood there and back. Are there any other options in missing here? Thanks!

Here’s where my problem lies. This shop isn’t going to be an everyday use shop, at least not the large power draw tools anyway. I have a solar system that one of the wonderful members here helped me get designed properly (thank you FilterGuy !) and with the addition of some used solar panels we have been cruising along in the house perfectly with 0 generator usage.

Okay. So my dilemma, one of the first tools I have purchased for this shop is a woodmaster 718 helical planer, it’s a beast of a machine, with an equally beastly electric requirement. In operation it uses up to 5 electric motors. The main planer drive is a farm duty 5hp motor, then a 5hp dust collector, 2-3.5hp routers and a 1/8hp feed motor. My aimes 6000 watt 18,000 surge inverter definitely was not a fan of the 5hp motor (be nice I know I’m a dummy for even trying, I didn’t realize motors can draw up to 5x rated amps on startup) and now I’m at a dilemma. I think my only option is a pto powered generator for my tractor (38.3 hp at the pto) to run something like this at home. I do have the option of a shop in town with grid power but then I have to transport all my wood there and back. Are there any other options in missing here? Thanks!