Jasgeer

New Member

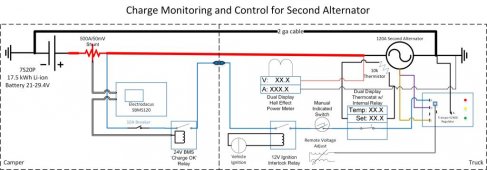

Here is an example of using a separate alternator for charging a Lithium battery (when the voltage needs to be different). I have seen many others. Many diesel trucks come from the factory with dual alternators and it is generally possible to separate them into two charging systems.

workingonexploring.com

workingonexploring.com

Adding a 2nd Alternator for Direct Lithium Battery Charging

Lithium Battery & Solar Setup My camper battery is a 24V nominal system of 35 Nissan leaf battery packs. Each pack contains 4 cells of Lithium Manganese Nickel Oxide (LMO) chemistry. They are a…

workingonexploring.com

workingonexploring.com

Attachments

Last edited: