You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone ever build a system to run efficiently @ 11,100 ft?

- Thread starter Crafty Sasquatch

- Start date

Conformal coating is a good idea in theory but in practice it'll be very hard to achieve 100 % coverage of the problematic areas for reasons already quoted before. I would add that even if you achieve 100 % coverage the PCB itself can and will absorb humidity so if the inverter is not kept in a very dry environment then conformal coating might not do much.

Not everything needs to be treated, only the high voltage areas, the DC side isn't a concern here (altho at 48 V you can start to have problems, but 12 or 24 is fine).

My approach would be to analyze the boards, see where the clearance and creepage distances are too small, and only correct the problematic areas. With any luck there will be few of them. Here clearance should be fine in most cases but creepage is where you will likely find the most problems. Clearance will be hard to correct and conformal coating or potting of the affected area will likely be the only solution. Creepage is usually easily corrected with a dremel provided there's no trace(s) that would be cut in the path you want to cut... Example of anti-tracking slots: https://i.ytimg.com/vi/BAJZpNDjiIA/maxresdefault.jpg

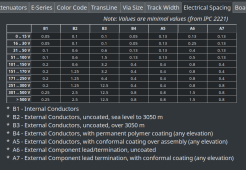

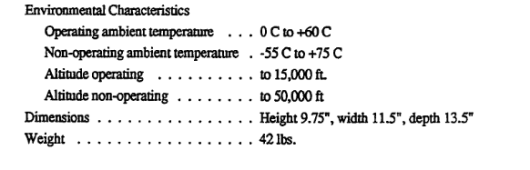

Here's a table provided by Kicad (B3 column is the one you want to use; keep in mind a 240 V inverter will actually have voltages of at least 340 V peak):

Not everything needs to be treated, only the high voltage areas, the DC side isn't a concern here (altho at 48 V you can start to have problems, but 12 or 24 is fine).

My approach would be to analyze the boards, see where the clearance and creepage distances are too small, and only correct the problematic areas. With any luck there will be few of them. Here clearance should be fine in most cases but creepage is where you will likely find the most problems. Clearance will be hard to correct and conformal coating or potting of the affected area will likely be the only solution. Creepage is usually easily corrected with a dremel provided there's no trace(s) that would be cut in the path you want to cut... Example of anti-tracking slots: https://i.ytimg.com/vi/BAJZpNDjiIA/maxresdefault.jpg

Here's a table provided by Kicad (B3 column is the one you want to use; keep in mind a 240 V inverter will actually have voltages of at least 340 V peak):

Crafty Sasquatch

New Member

- Joined

- Nov 18, 2022

- Messages

- 13

Maybe Will can send me all those sea level inverters he has laying around and we can try out some of y'alls crazy ideas. The least crazy being dielectric oil. I used to service EB welders in a previous life and all the high voltage was dunked in an oil filled tank but it had an oil cooler on it to keep the oil cool. So now we are causing a nother issue with a solution. This is not ideal when solving problems.

The military has the right idea when having stuff made for them it's a shame the rest of society aren't as demanding as the military standards.

The military has the right idea when having stuff made for them it's a shame the rest of society aren't as demanding as the military standards.

More insults.... I was going to provide more information that might help you, but that would be crazy.we can try out some of y'alls crazy ideas.

The military specifies the standards they expect their products to meet, then they pay for a product to meet those standards. You don't seem to understand that you are asking why everybody doesn't overpay for something they don't need just because you want something better and you want it now and you want it cheap.The military has the right idea when having stuff made for them it's a shame the rest of society aren't as demanding as the military standards.

He was wrong about that, too. Try pulling your camper up the grade on I-80 through the Eisenhower Tunnel with your half ton pickup. If you don't do your homework and pay for the correct truck and engine, you will end up going 40 MPH with your foot on the floor. By the time you get to the top, the radiator will have spewed its contents, leaving you with an overheated heap on the side of the road.I'm still stuck on the car analogy in a DIY forum. ?

Some truck manufacturers actually use that as an engineering test. Some don't; they leave it as an exercise for the buyer.

[...] and we can try out some of y'alls crazy ideas.

So using proper techniques like conformal coating and anti-tracking slots which are the industry standard is crazy?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,660

The oil fill does seem like an interesting and practical idea. Recommendations on which oil to use?

Oil in transformers degrades due to partial discharge (solid dielectrics can have same problem), but I don't think that will be the case for these relatively low voltages.

The SF6 I suggested should work, but it is getting restricted as a global warming contributor. For 11,000' operation, air pressure is about 65% of sea level, so "clearance" distances would need to increase 50% to maintain same point on the pressure x distance axis of Paschen curve (number of atoms or multiple of mean free path between electrodes.) Easy enough design parameter if considered up front, also some IC packages might be a problem.

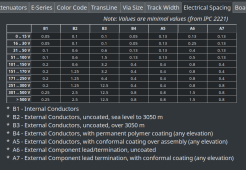

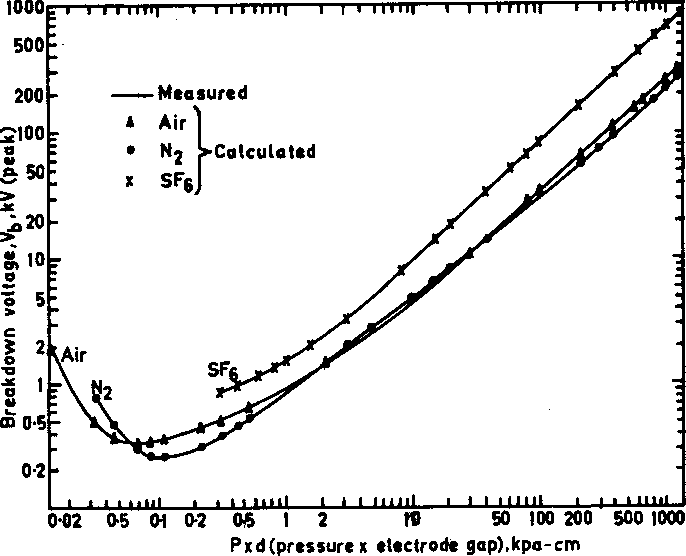

SF6 is used in pretty extreme high voltage situations. Nitrogen and air (of which it makes up 78%) have same Paschen curve. Of several common gasses, N2 has highest withstand voltage for a given pressure x distance product:

en.wikipedia.org

en.wikipedia.org

SF6 is better than air and N2, but not by as much as I expected. 2x the voltage at lower pressures, 3x at right hand side of chart:

www.semanticscholar.org

www.semanticscholar.org

Was thinking some other gas would be suitable, but haven't found one.

Several of the popular refrigerants are mentioned. Need to find Paschen curves for them:

en.wikipedia.org

en.wikipedia.org

R134A has 85% the dielectric strength of SF6:

There, maybe I've found a $20 fix for you.

Crazy enough for you all? ?

Oil in transformers degrades due to partial discharge (solid dielectrics can have same problem), but I don't think that will be the case for these relatively low voltages.

The SF6 I suggested should work, but it is getting restricted as a global warming contributor. For 11,000' operation, air pressure is about 65% of sea level, so "clearance" distances would need to increase 50% to maintain same point on the pressure x distance axis of Paschen curve (number of atoms or multiple of mean free path between electrodes.) Easy enough design parameter if considered up front, also some IC packages might be a problem.

SF6 is used in pretty extreme high voltage situations. Nitrogen and air (of which it makes up 78%) have same Paschen curve. Of several common gasses, N2 has highest withstand voltage for a given pressure x distance product:

Paschen's law - Wikipedia

SF6 is better than air and N2, but not by as much as I expected. 2x the voltage at lower pressures, 3x at right hand side of chart:

Figure 1 from Analysis of Paschen Curves for air, N2 and SF6 Using the Townsend Breakdown Equation | Semantic Scholar

Fig. 1: Measured and calculated Paschen curves for air, N2 and SF6 - "Analysis of Paschen Curves for air, N2 and SF6 Using the Townsend Breakdown Equation"

Was thinking some other gas would be suitable, but haven't found one.

Several of the popular refrigerants are mentioned. Need to find Paschen curves for them:

Dielectric gas - Wikipedia

R134A has 85% the dielectric strength of SF6:

There, maybe I've found a $20 fix for you.

Crazy enough for you all? ?

Recommendations on which oil to use?

Pure mineral oil is usually what's used in the DIY world for high voltage stuff because it's the only one that can be bought easily and for a reasonable cost (usually available as baby oil, be careful about additives like scents, you want pure oil).

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,660

Of course, you might also have a problem with electrical discharges elsewhere in your system, beyond the inverter.

Fortunately, there is a solution:

www.esa.int

www.esa.int

Just fill the entire house (make sure walls can withstand the pressure.)

Fortunately, there is a solution:

Liquid Ventilation and Water Immersion

Is there an example design in nature for the perfect acceleration shield? In effect, there is, and it is the egg. We studied the coupling of water immersion with liquid breathing as a possible approach for the “perfect G suit”.

Just fill the entire house (make sure walls can withstand the pressure.)

He was wrong about that, too. Try pulling your camper up the grade on I-80 through the Eisenhower Tunnel with your half ton pickup. If you don't do your homework and pay for the correct truck and engine, you will end up going 40 MPH with your foot on the floor. By the time you get to the top, the radiator will have spewed its contents, leaving you with an overheated heap on the side of the road.

Some truck manufacturers actually use that as an engineering test. Some don't; they leave it as an exercise for the buyer.

Psst, it's I-70, but I get what you're saying. Lot's of folks end up with too much camper and not enough truck on that pass (11,013' elevation). Heck, even on I-80 you can have that problem with the wind.

Warpspeed

Solar Wizard

SF6 is usually used only at extremely high voltages.

For general purposes electrical equipment, dry nitrogen is usually preferred.

Its cheap readily available, and as Hedges says, the atmosphere already contains 78% nitrogen anyway.

Many newer automatic transmissions in cars now have a microprocessor brain, and all the gear shifting is done by solenoid valves within the transmission. Consequently there is a lot of wiring and electrical stuff immersed in very hot transmission fluid.

Transmission fluid has very good long term thermal and electrical properties. There may be a superior oil available for very high voltages, but its probably going to be more difficult to obtain. Automatic transmission fluid does work very well in electrical equipment, and would be my choice.

For general purposes electrical equipment, dry nitrogen is usually preferred.

Its cheap readily available, and as Hedges says, the atmosphere already contains 78% nitrogen anyway.

Many newer automatic transmissions in cars now have a microprocessor brain, and all the gear shifting is done by solenoid valves within the transmission. Consequently there is a lot of wiring and electrical stuff immersed in very hot transmission fluid.

Transmission fluid has very good long term thermal and electrical properties. There may be a superior oil available for very high voltages, but its probably going to be more difficult to obtain. Automatic transmission fluid does work very well in electrical equipment, and would be my choice.

Oops, I'll call that a typo... Thanks for the correction.Psst, it's I-70

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,660

SF6 is usually used only at extremely high voltages.

For general purposes electrical equipment, dry nitrogen is usually preferred.

Its cheap readily available, and as Hedges says, the atmosphere already contains 78% nitrogen anyway.

Trouble is, unless you pressurize it, dry nitrogen at 11,000 feet won't protect against arcing any more than air at the same pressure.

Maybe R134A would extend operating altitude to there from what data sheet says.

Otherwise, mineral oil or the ATF you suggest might be an option.

Hope there aren't any radio devices inside; dielectric constant shift might de-tune them.

Mike 134

Solar Enthusiast

I have to laugh at you wanting cheap while living at 11,000 feet. Nothing you have at 11,000 feet was cheap to get there, unless your' living in a carboard box. access road, lumber, travel time...... It is cheaper living on an island bringing everything by boat.

Warpspeed

Solar Wizard

That is quite true, but the idea IS to pressurize the nitrogen, to at least sea level pressure.Trouble is, unless you pressurize it, dry nitrogen at 11,000 feet won't protect against arcing any more than air at the same pressure.

Maybe R134A would extend operating altitude to there from what data sheet says.

Otherwise, mineral oil or the ATF you suggest might be an option.

Hope there aren't any radio devices inside; dielectric constant shift might de-tune them.

That brings back the thermal and insulating properties back to sea level performance.

For a back yard effort, I would expect oil to be the most practical solution.

Its already used in many applications, its nothing startlingly new.

OzSolar

Whatever you did, that's what you planned.

The universe has intervened and shown me your inverter. I was asked to help with the settings on an inverter today so I dug out the manual. While flipping though the pages I came upon the specifications page and "ta-da" the perfect inverter has been revealed.

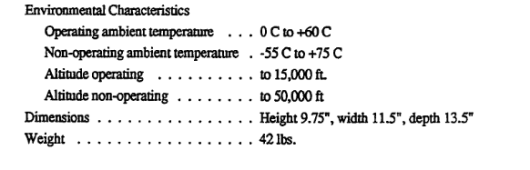

The Trace 2500 series. $1905 for the 48v model, 12v is cheaper and we all know cheap is better, made in the USA, rated to 15,000' operating and 50,000' for storage.

One tiny problem. You just need a time machine. It hasn't been made since ~1995. The good news is there are still some living in the wild and the owners using them every day don't even know they are museum pieces. (Yes, I installed these new... daham... I don't feel that old)

The Trace 2500 series. $1905 for the 48v model, 12v is cheaper and we all know cheap is better, made in the USA, rated to 15,000' operating and 50,000' for storage.

One tiny problem. You just need a time machine. It hasn't been made since ~1995. The good news is there are still some living in the wild and the owners using them every day don't even know they are museum pieces. (Yes, I installed these new... daham... I don't feel that old)

There are dielectric fluids that are used for liquid cooling of computer equipment that would work. 3M has two major lines; I know one is stupidly expensive but I thought the other one was fairly affordable and manageable. They are a lot easier to use with circuits that aren't designed for liquid cooling. We used them for a client that had a long-running application (>5 years); mineral and synthetic oil cause problems with a lot of the connectors over longer durations.

Learned something about the potting compounds here; I thought it was much easier to do aftermarket. I knew someone that did it for marine electronics, and while tedious I didn't think he needed to use a vacuum chamber for it. Guess I didn't fully understand the process.

Learned something about the potting compounds here; I thought it was much easier to do aftermarket. I knew someone that did it for marine electronics, and while tedious I didn't think he needed to use a vacuum chamber for it. Guess I didn't fully understand the process.

Warpspeed

Solar Wizard

Double post.

Last edited: