sunrise

New Member

- Joined

- Jul 16, 2020

- Messages

- 206

Hi all,

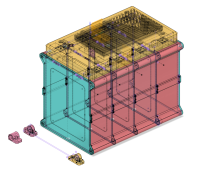

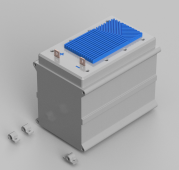

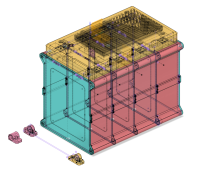

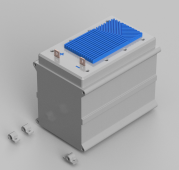

A few months ago I made a post about my 3D printed battery design based on EVE 304ah cells. The project was completed a month ago but I have been very busy with work since then.

I just managed to find some time to push the design to Github

https://github.com/xiaotian/300

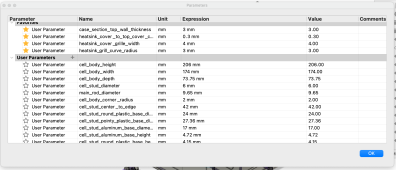

The Fusion models are fully parametric, so you can tweak dimensions of cells, clearance, etc, to fit your needs.

For beginners, some instructions, BOM would be great, I will find time to add these later.

For folks that didn't see my original post, it's a very compact battery (304ah) with 200A JBD BMS. The size is about the same as a Battleborn 100ah unit. It's been installed in my 16 Airstream. I started the project because there is no commercially available product (>= 300ah) that fits in the space in my Airstream. It's been powering the 2000w inverter and even a 13500BTU A/C. I am super happy with it.

Thank you for being patient and happy building!

A few months ago I made a post about my 3D printed battery design based on EVE 304ah cells. The project was completed a month ago but I have been very busy with work since then.

I just managed to find some time to push the design to Github

https://github.com/xiaotian/300

The Fusion models are fully parametric, so you can tweak dimensions of cells, clearance, etc, to fit your needs.

For beginners, some instructions, BOM would be great, I will find time to add these later.

For folks that didn't see my original post, it's a very compact battery (304ah) with 200A JBD BMS. The size is about the same as a Battleborn 100ah unit. It's been installed in my 16 Airstream. I started the project because there is no commercially available product (>= 300ah) that fits in the space in my Airstream. It's been powering the 2000w inverter and even a 13500BTU A/C. I am super happy with it.

Thank you for being patient and happy building!