MattMan119

Solar Geek

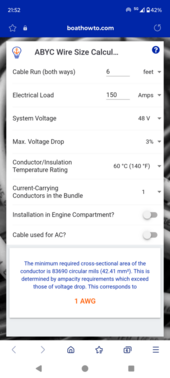

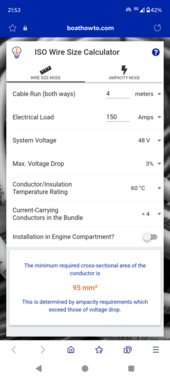

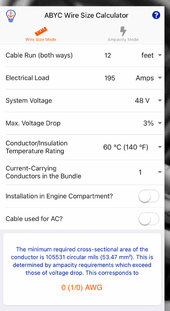

I upgraded my main cable to 1/0 from the 600a bus to the inverter .. I had extra so I updated all the cables from batteries to bus to the 1/0 also.. but wanted to make sure 1/0 should be enough to support 3x48v batteries running to bus then to 6000xp inverter without worries?

Oh you can see my security frame that I built to hold them in the RV bay.

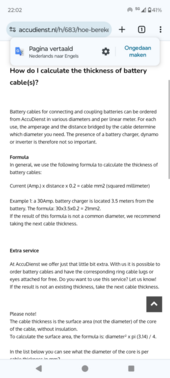

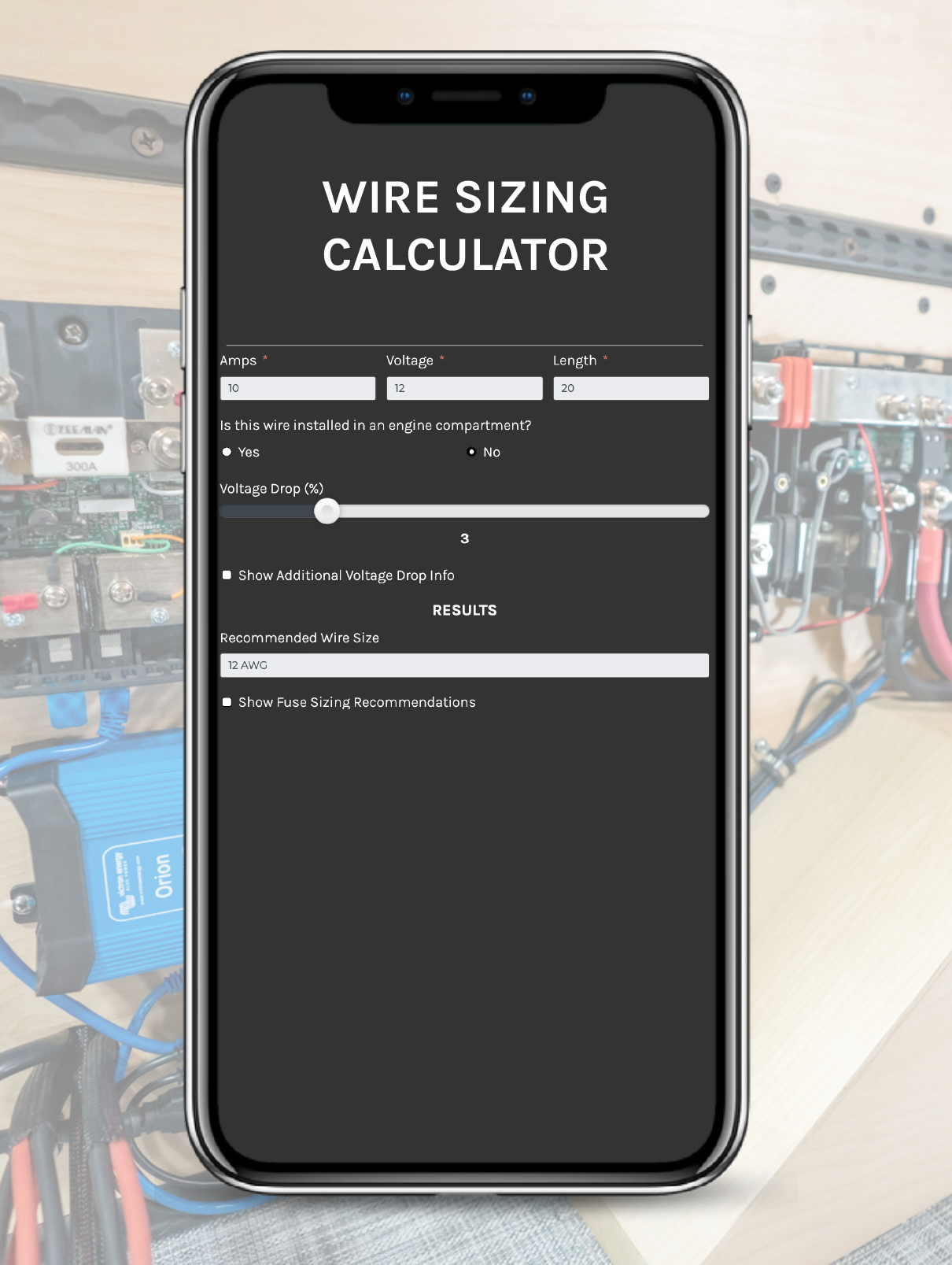

Just want some reassurance that 1/0 can handle max load and charge .. there seems to be a lots of conflicting details on DC amp wire max compacity.

Thanks,

MattMan

Oh you can see my security frame that I built to hold them in the RV bay.

Just want some reassurance that 1/0 can handle max load and charge .. there seems to be a lots of conflicting details on DC amp wire max compacity.

Thanks,

MattMan