Genawin

New Member

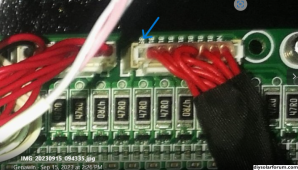

Hello this is my first time posting , I wondered if anyone has experienced similar ? Cell 9 of 16 x 300ah is reading up to 300mv higher on charge at 50a and 200mv lower on similar discharge than all the others which are closely balanced this indicated to me that I had a high resistance cell ,I have now replaced the cell and the problem remains so I investigated further to find that the BMS is falsely reading this cell. I also found that the correct cell voltage is getting back to the pcb so the problem appears to be the BMS itself , I have tried to identify which BMS I have and it appears to be a lot like a JBD or Heltec - the pcb is marked "VKL_01 ? , I'm able to use VKing V2.B to monitor, check history and do certain configurations but there doesn't appear to be any form of calibration to individual cell readings which doesn't surprise me , any help would be much appreciated.