If you plan to cast aluminum, it is pretty simple, but you can get old castings for free. Don't use structural pieces for casting. Old boat engine parts, transmission housings, etc. work great. Just make sure they aren't magnesium before you throw them in the pot.

You can separate the men from the boys somewhere around bronze casting. You can do it with more heat than aluminum, but you'll want to be much more careful.

Casting iron takes even more heat, and gets fairly pesky also. It is easy to burn off additives that can help give you better quality.

Casting steel is pretty much for superman. Lots of heat and tedious balancing of additives to get steel at all. I suspect you meant you want to cast iron, not steel.

Start with aluminum from old castings. Make your own furnace with fire brick and mortar. Use a decent blower to get the heat up. My friend made his crucible from steel pipe with a welded bottom. It would last about maybe five pours before the molten aluminum ate through it.

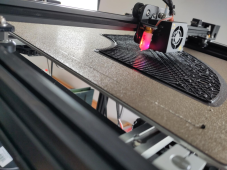

View attachment 133747