so here I finally think I can demonstrate the tiny bit of extra voltage producing capabilities of iron filled coil legs.

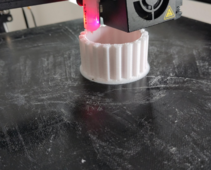

And I need to make a correction as the latest coil was double wired as the one before it. This means 200, 400, 200. not 150, 300, 150.

Both coils were ran in the same conditions as they were ran in parallel.

17mm spacing between the magnets on opposite disks.

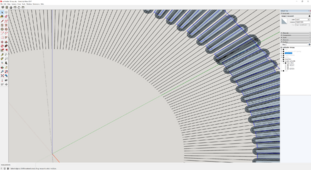

the coils

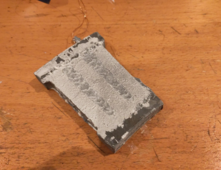

the disks we already know how they are but to make sure things do not get bumping up or down then I used this.

hahah look how almost , almost, perfect the magnets are spaced now. But they really are not

there is one spot in where 2 of them show clear signs of misalignment as that is where the 2 half circles meet.

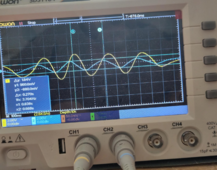

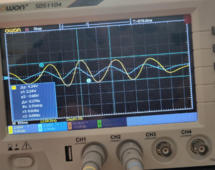

Now let us look at what the previous 100,200,100 coil did without any iron added.

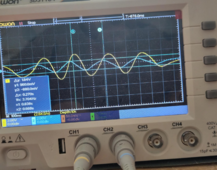

Now let us look at what the 200, 400, 200 did with iron powder added.

Mind you they are both running in the same run.

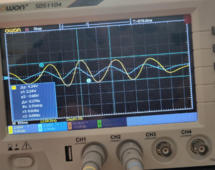

How ever slightly. The voltage generation ability seems in this early stage of testing to be more than doubled. Doubled sure because of the double amount of wires. But more than that might be because of the iron powder added.

Now once again this could have been anything mundane. Like not both coils are equally well positioned. I will admit that.

But that does not mean I should not try and pursue this line of thinking. Only when it is established without a doubt that adding iron powder to the coil legs (never mind the cores of the coils) does more harm than good then it is time to abandon the concept agreed?