brandnewb

Going for serious. starting as newb

incredible.

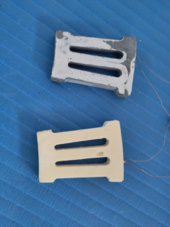

look what just arrived while I was quoting the A-Team

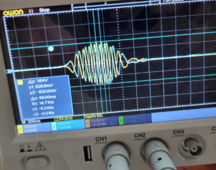

Now please do not expect immediate results as I will need some time to wrap my head around how to wire this machine.

And on a more sad note I am not sure that 3Kw is going to cut it I mean I have 11KW to spend so why not?!! hhaha then the costs would be just no longer justifiable other than showing off. Which I like sure but nah there needs to be a middle ground between showing off and just getting things done in a practical manner!

I mean I have 11KW to spend so why not?!! hhaha then the costs would be just no longer justifiable other than showing off. Which I like sure but nah there needs to be a middle ground between showing off and just getting things done in a practical manner!

{1}it was damned heavy too. What a bad timing for me to have gone through my back yesterday. It is as if there are higher powers trying to tell me something {/1}

{/1}

look what just arrived while I was quoting the A-Team

Now please do not expect immediate results as I will need some time to wrap my head around how to wire this machine.

And on a more sad note I am not sure that 3Kw is going to cut it

{1}it was damned heavy too. What a bad timing for me to have gone through my back yesterday. It is as if there are higher powers trying to tell me something

Last edited: