Bowlegs868

New Member

Guys, have a listen and tell me if this is normal...

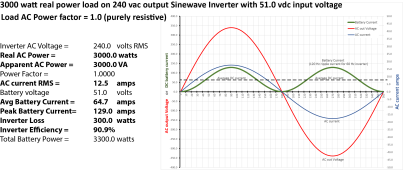

very informative... will have to re-read some time but my takeaway is that I need to look into quality DC breaker... any suggestions?Sinewave inverters or inverter/chargers DC current has 2x the sinewave frequency in ripple current. For 60 Hz AC the peak to peak 120 Hz ripple current is about twice the average DC current.

At moderate battery current this 120 Hz ripple current creates strong 120 Hz magnetic fields around battery lines, including any DC breakers.

A good quality breaker should not buzz but a good breaker mounted in a metal enclosure with a loose cover lid may buzz the loose metal lid due to the 120 Hz pulsing magnetic fields.

If you bring the positive and negative cables close together, they will cancel out most of the magnetic field.

The pulsing on and off of the buzz in your recording is likely the float charging cycle coming on and off to maintain the float voltage on battery.

I would not worry about it unless the sound bothers you. If it is the breaker, it is likely the arc suppressor fins are made of some magnetic material that is vibrating in the plastic breaker housing.very informative... will have to re-read some time but my takeaway is that I need to look into quality DC breaker... any suggestions?

Just out of curiosity, what breaker do you have and how much current was going thru it?that I need to look into quality DC breaker.

I have four 350W (40.15V, 8.72A) panels...Just out of curiosity, what breaker do you have and how much current was going thru it?

I see there's a lot of mentions about inverter stuff so I have to add that the DC breakers are connected to the solar panelsI would not worry about it unless the sound bothers you. If it is the breaker, it is likely the arc suppressor fins are made of some magnetic material that is vibrating in the plastic breaker housing.

On the graph, the green curve is what the inverter battery line current actually looks like.

Battery monitors and BMS's have an averaging low pass filter to remove the 120 Hz to get just the average DC current value.

View attachment 89678

Those DC breakers look top notch, i was kind of expecting something cheap or improper.DC breakers are connected to the solar panels

four 350W (40.15V, 8.72A)Those DC breakers look top notch, i was kind of expecting something cheap or improper.

I wonder if there would be something interesting to be learned testing without the surge protectors?

Lets work onward. What does your array look like feeding these breakers?

PV panels should not be subjected to any ripple current or you will be losing available PV power. Sun illumination creates a DC current source. To extract the most power from the panels it is important that the load is smooth and constant at the illumination based appropriate maximum power point loading with no ripple induced loading variance due to inverter/charger.

It is rare to rely on capacitors on PV panel output for single phase AC load ripple elimination. Enphase did this on their original micro-inverters and quickly changed their approach on their next model.I would expect PV panels to feed capacitor on input of SCC, fairly steady voltage (and therefore panel current) with slight triangle waveform. Buck converter switches so battery is charged through inductor from capacitor, then coasts through inductor and diode to negative. AC component of current in inductor (and through breakers) can be larger than AC component in PV, with capacitor filter making the difference.