Bluedog225

Texas

- Joined

- Nov 18, 2019

- Messages

- 2,917

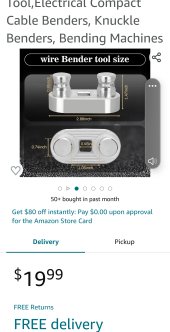

I’ve heard there is a tool for bending thick wire to facilitate installation in tight spaces. Would someone post an example?

And in practice, I guess you would put the bend in, then cut the cable, then crimp the lug on. Correct?

Is this not needed with the fine strand stuff like welding wire? Only for the thicker stranded material?

Also, I’ve never had a good wire stripper. I’ve always been fine just using a carpet knife. Are those things super handy? Or just nice to have.

Thanks

And in practice, I guess you would put the bend in, then cut the cable, then crimp the lug on. Correct?

Is this not needed with the fine strand stuff like welding wire? Only for the thicker stranded material?

Also, I’ve never had a good wire stripper. I’ve always been fine just using a carpet knife. Are those things super handy? Or just nice to have.

Thanks