You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

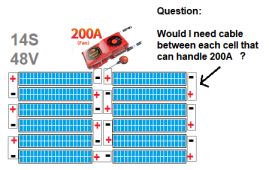

Cable size between cells in 46v 14S 200A configuration?

- Thread starter Modular Hippo

- Start date

BentleyJ

Solar Wizard

Yes, because when in series, its a single circuit that all current passes through, there are no alternate paths.

I personally like welding cable because its so flexible and easy to work with.

I personally like welding cable because its so flexible and easy to work with.

Modular Hippo

New Member

Hi BentleyJ - Big thank you for confirming - I do not think that I will ever draw more than 100A continuous BUT like to stay above that threshold to give me some headroomYes, because when in series, its a single circuit that all current passes through, there are no alternate paths.

I personally like welding cable because its so flexible and easy to work with.

Trying to work out cable size needed between cell 40p cell packs (18650) if I am building a system that needs to be able to support 200A. Am I right in thinking that between each cell pack I would also need to have a cable that supports 200A?

Grateful if someone can confirmThanks // MH

View attachment 161560

This posting worries me.

Sorry if I sound like a damp squib but I have serious safety concerns about the wisdom of embarking on a project to drive a 20kW boat motor with 540 18650 cells if you are asking such as basic question as the above.

I am all for doing as much DIY as we can. But from this thread and others you have posted on here I'd strongly recommend that you have your design/implementation thoroughly checked over from someone with enough knowledge and experience, before you set sail. For the safety of you and all aboard.

The last thing you want is a fire on a boat - been there done that

Modular Hippo

New Member

Hi SeaGal - Thank you for your feedback and I appreciate your concerns. The 18650 is not the final solution for the boat (boat still under production and will not touch water for another 2 years at least). The 540 18650 project is more for me to be able to get my hands dirty, learn about the components and the related risks as I am moving forward. As apparent in my posts I am a beginner with very little experience but picking new things up daily as I move forwardThis posting worries me.

Sorry if I sound like a damp squib but I have serious safety concerns about the wisdom of embarking on a project to drive a 20kW boat motor with 540 18650 cells if you are asking such as basic question as the above.

I am all for doing as much DIY as we can. But from this thread and others you have posted on here I'd strongly recommend that you have your design/implementation thoroughly checked over from someone with enough knowledge and experience, before you set sail. For the safety of you and all aboard.

The last thing you want is a fire on a boat - been there done that???

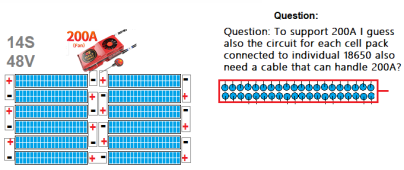

With confirmation that the cells need 200A cable between them my next question is to figure out if each individual cable that is directly connected to the individual 18650's need to be 200A as well? I guess so as explained to me it is linked to the continues loop so potentially 200A in theory could pass through?

@BentleyJ - Something you can confirm?

Super grateful for you sharing your knowledge!!

Thanks // Modular Hippo

LOL.. The fire I had on a 9m yacht was about 25 years ago (yes, I'm old) when I dropped a cloth napkin on the gas stove! The only battery on the boat was a 12V lead-acid one to start the Yanmar.

We put it out quickly with the extinguisher, but was just so scary seeing such big flames close to seating and the wooden lined interior of our Beneteau, when a good half mile offshore. Wasn't a relaxing cuppa tea that day!

The answer to your next question - if I understand the question correctly - is no.

Any cable / connection to each individual cell will need to safely handle the maximum current through that cell + best to allow a 30% safety margin.

So in your example, if you are drawing 200A with 40 cells in parallel to each other, each cell would (assuming they have the same resistance as each other) pass through 5A each (5 x 40 being 200). Add some margin in though in case some cells are duff and have a high resistance. In that case the remaining cells will take the bulk of the current.

The basics are covered here (though ignore the sections on capacitors and inductors)...

en.wikipedia.org

en.wikipedia.org

Also, this pdf makes good reading if you can't get to sleep one night...

HTH.

We put it out quickly with the extinguisher, but was just so scary seeing such big flames close to seating and the wooden lined interior of our Beneteau, when a good half mile offshore. Wasn't a relaxing cuppa tea that day!

The answer to your next question - if I understand the question correctly - is no.

Any cable / connection to each individual cell will need to safely handle the maximum current through that cell + best to allow a 30% safety margin.

So in your example, if you are drawing 200A with 40 cells in parallel to each other, each cell would (assuming they have the same resistance as each other) pass through 5A each (5 x 40 being 200). Add some margin in though in case some cells are duff and have a high resistance. In that case the remaining cells will take the bulk of the current.

The basics are covered here (though ignore the sections on capacitors and inductors)...

Series and parallel circuits - Wikipedia

Also, this pdf makes good reading if you can't get to sleep one night...

HTH.

Modular Hippo

New Member

Happy you made it back to the docks in one piece after your fire adventureLOL.. The fire I had on a 9m yacht was about 25 years ago (yes, I'm old) when I dropped a cloth napkin on the gas stove! The only battery on the boat was a 12V lead-acid one to start the Yanmar.

We put it out quickly with the extinguisher, but was just so scary seeing such big flames close to seating and the wooden lined interior of our Beneteau, when a good half mile offshore. Wasn't a relaxing cuppa tea that day!

The answer to your next question - if I understand the question correctly - is no.

Any cable / connection to each individual cell will need to safely handle the maximum current through that cell + best to allow a 30% safety margin.

So in your example, if you are drawing 200A with 40 cells in parallel to each other, each cell would (assuming they have the same resistance as each other) pass through 5A each (5 x 40 being 200). Add some margin in though in case some cells are duff and have a high resistance. In that case the remaining cells will take the bulk of the current.

The basics are covered here (though ignore the sections on capacitors and inductors)...

Series and parallel circuits - Wikipedia

en.wikipedia.org

Also, this pdf makes good reading if you can't get to sleep one night...

HTH.

Are these new cells or harvested cells?

I recommend getting fused sheets to parallel the cels with, ESPECIALLY if harvested cells.

If any fail, the fuse pops, shifting the load around the bad cell.

I recommend getting fused sheets to parallel the cels with, ESPECIALLY if harvested cells.

If any fail, the fuse pops, shifting the load around the bad cell.

BentleyJ

Solar Wizard

14S implies the 18650 cells are 3.7V type? Curious, isn't relevant to your question.With confirmation that the cells need 200A cable between them my next question is to figure out if each individual cable that is directly connected to the individual 18650's need to be 200A as well? I guess so as explained to me it is linked to the continues loop so potentially 200A in theory could pass through?

View attachment 161796

Something you can confirm?

Based on the drawing its a 40 cell parallel pack so each cell, at maximum load, would contribute 200A/40 = 5A. That seems like a very high discharge C rate!! Maybe need to lower your expectations of this battery pack to 100A.

The answer to your question is: It depends on how each cell is connected to the main + & - terminal of the cell pack.

Scenario 1) Each of the 40 cells has an individual + & - wire that connects to the main terminals. So each wire must carry 5A with minimal voltage drop. Wow, that would be a mess.

Scenaro 2) Cells are connected together in groups of 5 parallel with the typical spot welded flat metal strap. Then 8 wires are used to connect the 8 groups of 5 cells to the main terminals. The flat metal strap as well as each wire must support 25A.

Similar threads

- Replies

- 4

- Views

- 259

- Replies

- 3

- Views

- 234

- Replies

- 28

- Views

- 1K

- Replies

- 84

- Views

- 4K