Modular Hippo

New Member

Hi Forum

I am currently building a boat and instead of installing a diesel engine I am planning to use an electric motor, battery bank and wind/solar/Hydro generator as rechargeable source. Before I can start looking at the actual rechargeable source I am focusing on the actual battery bank. The idea is to have a dedicated 'Lithium iron phosphate' bank for the motor, and a secondary '18650 3.6V, Lithium-Ion' bank for the boat itself. I would like to build the secondary bank to a spec where it also can be used as an emergency/backup energy source for the motor in case of ever needed. The battery choice for the secondary bank may not be the most suitable but as I have access to 18650's and enjoy the challenge/tinkering that is what I am set on doing. I have started with my secondary source (3.6V, Lithium-Ion - 18650's) and trying to work out what size BMS/s I would need, as well as how many 1865's per battery I would need.

This is what I know:

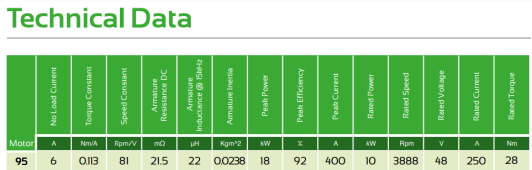

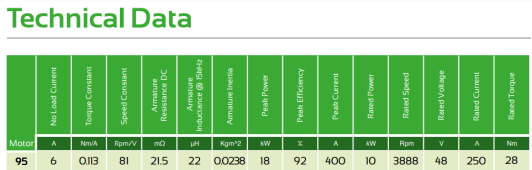

1. The motor will be something like this one or similar:

Rated Votage: 48V

Rated Power 10kW

RPP: 3888

Torque:28Nm

Rated Current: 250 Amp

Peak Current 400 Amp

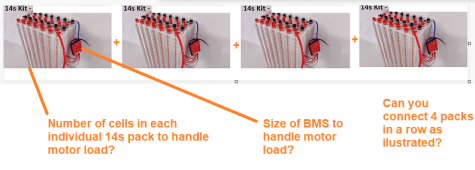

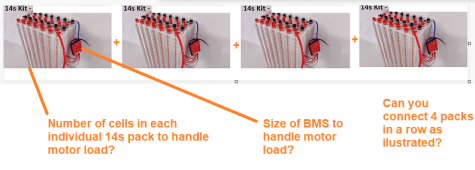

2. I am thinking a 14S system (48V) where I potentially can connect multiple battery banks together to increase the Amperage.

Image for illustration purpouses only:

Questions:

- Is it the BMS that determine the load & charge max currents, in other word if I the motor has a peak current current of 400 Amp then I would also need a BMS that can handle 400 Amp (or do I maybe need an even larger BMS)?

- How would I calculate how many 18650 batteries I would need in each of the 14s packs to be able to handle the load?

- Can you have multiple individual batteries, each with their own BMS and connect them together?

Any thoughts, ideas or pointers of where I can start when calculating this highly appreciated

Thanks

Henrik

I am currently building a boat and instead of installing a diesel engine I am planning to use an electric motor, battery bank and wind/solar/Hydro generator as rechargeable source. Before I can start looking at the actual rechargeable source I am focusing on the actual battery bank. The idea is to have a dedicated 'Lithium iron phosphate' bank for the motor, and a secondary '18650 3.6V, Lithium-Ion' bank for the boat itself. I would like to build the secondary bank to a spec where it also can be used as an emergency/backup energy source for the motor in case of ever needed. The battery choice for the secondary bank may not be the most suitable but as I have access to 18650's and enjoy the challenge/tinkering that is what I am set on doing. I have started with my secondary source (3.6V, Lithium-Ion - 18650's) and trying to work out what size BMS/s I would need, as well as how many 1865's per battery I would need.

This is what I know:

1. The motor will be something like this one or similar:

Rated Votage: 48V

Rated Power 10kW

RPP: 3888

Torque:28Nm

Rated Current: 250 Amp

Peak Current 400 Amp

2. I am thinking a 14S system (48V) where I potentially can connect multiple battery banks together to increase the Amperage.

Image for illustration purpouses only:

Questions:

- Is it the BMS that determine the load & charge max currents, in other word if I the motor has a peak current current of 400 Amp then I would also need a BMS that can handle 400 Amp (or do I maybe need an even larger BMS)?

- How would I calculate how many 18650 batteries I would need in each of the 14s packs to be able to handle the load?

- Can you have multiple individual batteries, each with their own BMS and connect them together?

Any thoughts, ideas or pointers of where I can start when calculating this highly appreciated

Thanks

Henrik