AgroVenturesPeru

New Member

- Joined

- Sep 19, 2020

- Messages

- 411

I currently have a victron 250/100 on my system. The unit needs replacement.

Was thinking about downsizing until I can get a replacement 250/100.

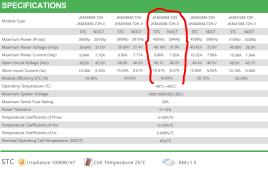

PV array is 4s4p. Highest PV voltage I've ever seen is 190V.

Unfortunately, I think the PV array is the limiting factor here. Since each string is four 400w panels in series I will always need a charge controller with at least 200V capacity. Even if I were to disconnect 3 out of the 4 strings from the MC4 connectors.

Would be nice to get a cheap charge controller such as a 100/85, while the current one is in for service. But is that even feasible?

Here's my stringbox:

And the inside (I hadn't installed the cable gland or the output PV wires yet when this photo was taken:

Also, I have three of these batteries FWIW for the amperage calculations for the charge controller's output:

Was thinking about downsizing until I can get a replacement 250/100.

PV array is 4s4p. Highest PV voltage I've ever seen is 190V.

Unfortunately, I think the PV array is the limiting factor here. Since each string is four 400w panels in series I will always need a charge controller with at least 200V capacity. Even if I were to disconnect 3 out of the 4 strings from the MC4 connectors.

Would be nice to get a cheap charge controller such as a 100/85, while the current one is in for service. But is that even feasible?

Here's my stringbox:

And the inside (I hadn't installed the cable gland or the output PV wires yet when this photo was taken:

Also, I have three of these batteries FWIW for the amperage calculations for the charge controller's output: