xml

New Member

- Joined

- Nov 19, 2022

- Messages

- 4

Hi!

Im a bit of an amateur so maybe the reply will be "if you dont know what you are doing, dont do it" ?

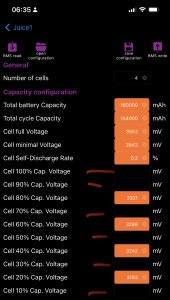

Anyway I got instructions from my supplier that are using an older version of xiaoxiang app which only has 80% 60% 40% 20% settings for cap voltage, the latest version wants for 100, 90, 80, 70, 60, 50, 40, 30, 20, 10

I tried to reverse the calculations but couldnt get any formula that makes sense.

Based on the values you see in the screenshot, what would you fill in the blanks? I guess 3552 for 100%

Im a bit of an amateur so maybe the reply will be "if you dont know what you are doing, dont do it" ?

Anyway I got instructions from my supplier that are using an older version of xiaoxiang app which only has 80% 60% 40% 20% settings for cap voltage, the latest version wants for 100, 90, 80, 70, 60, 50, 40, 30, 20, 10

I tried to reverse the calculations but couldnt get any formula that makes sense.

Based on the values you see in the screenshot, what would you fill in the blanks? I guess 3552 for 100%