@MisterSandals Thanks for taking the time to educate me in the kiddie pool. Lets see how I did on the final exam!!!

The inverter and Cerbo pictured above will also be mounted on the forward wall. I don't have pro 3d software just basic paint. It is likely all components will end up mounted in the upper area if battery weight does not present an issue. If not It will likely become a flat wall with storage behind it.

all above image rights properties of respective owners. Used for educational purposes to help display plans for build.

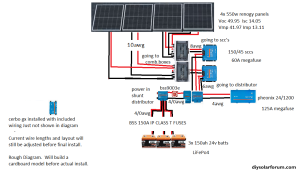

Power Assessment: 5kWh per day use. 7A (160w) constant draw with up to 30A (700W) spikes and maximum single circuit draws up to 70A (1700W).

Battery Requirement 24V 300-400Ah (7680-10240)Wh (2 days panel production storage and potential for 300 amp overall max draw usage)

Victron Gear:

$436364 (O.B.$338) 2x SCC115045212 SmartSolar MPPT 150/45 controller accepts AWG2 at both PV input and battery output (The MPPT 150/45 requires minimum of 50A fuse and max 63A)(16mm²/AWG6)

(substitute model on open box SCC115045210 (tr model) (5.1"x 2.7"x 7.3") (2.75 lbs))

$169222 (O.B.$197) LYN060102000 Lynx Distributor (M8 Posts/Hole, 14Nm busbar terminals/interconnections, middle fused terminal bottom nut is 10Nm) (11.4"x 6.7"x 3.1") (4.85lbs)

$156 (O.B.$138) LYN020102000 Lynx Power In (M8 Posts/Hole, 14Nm busbar terminals/interconnections)

$400 PIN242120510 Victron Phoenix Inverter 24/1200 120V VE.Direct NEMA GFCI

*(O.B.$346 substitute model is PIN242122500 Victron Phoenix Inverter 24/1200 (14.3"x9.1"x4.6"),(16.3lbs), (max 4awg / 25mm2) (screw terminals))

$311374 (O.B.$330) LYN040102100 Lynx Shunt (7.5"x 3.1"x 6.4"), (33mA @ 24V consumption),(M8 Posts/Hole 14nm)

$79340 (O.B.$301) BPP900450100 Cerbo GX

Total $2220 (O.B. $1988)

Batteries:

$850 (x3) Cloudenergy 24V 150Ah (m8 screw terminal 16mm/5/16")

Total $2550

Wiring:

Wire Run total (-black & red+):

PV panels to combiner box awg10 (8)x 10'

Combiner Box to Controllers awg8 (4)x 5'

Controllers to Distributor awg6 (4)x 4'

Battery Bank to Power In awg4/0 (6)x 3'

Power In to Killswitch/shunt awg4/0 (2)x 6" (1)x15"

$96x(2) Amazon DIHOOL Combiner Box 2 in 1 out 25 Amp Fuse, 20-40kA 2P DC500V SPD, 50A DC 500V Breaker (3.0 N.m)

$60 Blue Sea Systems 9003E e-Series Battery Switch, 350A On/Off, Red (m10 3/8"), (3"x3"x1.5")

$25 BEP Marinco 770 battery switch 400A 48v (located on + busbar between lynx shunt and lynx Distributor) (There is an error in above diagram)

$25x(4) ???windyNation??? 10 awg USE-2 or RHH/RHW-2 PV wire MC4 connection (4)x sets (10')

($1.08/ft) batterycablesusa awg8 Marine Grade Tinned Copper Battery Cable UL 1426 (80A),(168 Stranding),(O.D. 0.27"),(0.08 lbs/ft)

$32

- 5'- no ends $8x(2) Red (combiner to scc)

- 5'- no ends $8x(2) Black (combiner to scc)

($1.42/ft) batterycablesusa awg6 Marine Grade Tinned Copper Battery Cable UL 1426 (120A),(266 Stranding),(O.D. 0.340"),(0.123 lbs/ft)

$32

-4'-5/16" lug one end $8 x(2) Red (SCC to Distributor)

-4'-5/16" lug one end $8 x(2) Black (SCC to Distributor)

($2.18/ft) batterycablesusa awg4 Marine Grade Tinned Copper Battery Cable UL 1426 (160A),(420 Stranding),(O.D. 0.405"),(0.185 lbs/ft)

$22

-4' 5/16"(m8) to No Lug $11x(1) Red (Distributor to Pheonix)

-4' 5/16"(m8) to No Lug $11x(1) Black (Distributor to Pheonix)

($10.66/ft) batterycablesusa awg4/0 Marine Grade Tinned Copper Battery Cable UL 1426 (445A),(2109 Stranding),(O.D. 0.735")(0.826 lbs/ft)

$360

- 6" 5/16"(m8) to 1/4"(m6) $13x (3) Red (Positive Battery Terminal to T fuse Block)

- 3' 5/16"(m8) to 1/4"(m6) $40x (3) Red (T fuse block to Power In)

-3' 5/16"(m8) to 5/16"(m8) $40x (3) Black (Negative Battery Terminal to Power In)

-6" 5/16"(m8) to 3/8"(m10) $13x (2) Red (Positive Power In to shutoff) (Shutoff to Lynx Shunt Postive)

-15" 5/16"(m8) to 5/16"(m8) $21x (1) Black (Negative Power In to Lynx Shunt Negative)

Total $738

Ferrules

(8)x 10awg pv inputs to combinerbox

(12)x 6awg (8)x combiner to SCCs,(4)x SCCs to Distributer)

(2)x 4awg Pheonix to Distributer

(suggestions here please)

>>> Ferrule supplier brand __________?

$__

>>> Klien crimper tool model #__________ ?

$__

Ring Lug Terminals

(specified and added when ordering wire)

Fuses

$57x(3) Blue Sea Systems Fuse Block 5007100 Class T Ignition Protected 160-200A, Maximum Torque (21.47 Nm), 72 in-lb (8.13 Nm) Mounting Fastner Size 1/4" (M6) Terminal Stud Size 1/4" (M6), (Battery Terminal Side of Bank Cable)

$43x(3) Blue Sea Systems 5114 Fuse A3T/Class T 150A Boating Fuse A3T/Class T 150A

$15 signaturesolar Victron MEGA-fuse 125A/32V (5-Pack) ((1)x Distributer Pheonix 24/1200)

$17 signaturesolar Victron Energy | MEGA-fuse 60A/32V (package of 5 pcs) ((2)xSCC to distributor)

$13 amazon 2x Littelfuse 60a 32v mega 0298060

$55 signaturesolar Victron Fuse CNN 325A/80V for Victron Lynx Shunt (1 pc) (lynx shunt)

$24 amazon Buss/Ferraz CNN 400A 48v

Total $447 (+ferrules/crimper)

Accessories:

$25 Ve.direct Bluetooth Dongle

$70 Victron Pheonix 12/375 (allows an earlier use of system in a 12v stage)

System Total $5955

The inverter and Cerbo pictured above will also be mounted on the forward wall. I don't have pro 3d software just basic paint. It is likely all components will end up mounted in the upper area if battery weight does not present an issue. If not It will likely become a flat wall with storage behind it.

all above image rights properties of respective owners. Used for educational purposes to help display plans for build.

Power Assessment: 5kWh per day use. 7A (160w) constant draw with up to 30A (700W) spikes and maximum single circuit draws up to 70A (1700W).

Battery Requirement 24V 300-400Ah (7680-10240)Wh (2 days panel production storage and potential for 300 amp overall max draw usage)

Victron Gear:

$436

(substitute model on open box SCC115045210 (tr model) (5.1"x 2.7"x 7.3") (2.75 lbs))

$169

$156 (O.B.$138) LYN020102000 Lynx Power In (M8 Posts/Hole, 14Nm busbar terminals/interconnections)

$400 PIN242120510 Victron Phoenix Inverter 24/1200 120V VE.Direct NEMA GFCI

*(O.B.$346 substitute model is PIN242122500 Victron Phoenix Inverter 24/1200 (14.3"x9.1"x4.6"),(16.3lbs), (max 4awg / 25mm2) (screw terminals))

$311

$79

Total $2220 (O.B. $1988)

Batteries:

$850 (x3) Cloudenergy 24V 150Ah (m8 screw terminal 16mm/5/16")

Total $2550

Wiring:

Wire Run total (-black & red+):

PV panels to combiner box awg10 (8)x 10'

Combiner Box to Controllers awg8 (4)x 5'

Controllers to Distributor awg6 (4)x 4'

Battery Bank to Power In awg4/0 (6)x 3'

Power In to Killswitch/shunt awg4/0 (2)x 6" (1)x15"

$60 Blue Sea Systems 9003E e-Series Battery Switch, 350A On/Off, Red (m10 3/8"), (3"x3"x1.5")

$25 BEP Marinco 770 battery switch 400A 48v (located on + busbar between lynx shunt and lynx Distributor) (There is an error in above diagram)

$25x(4) ???windyNation??? 10 awg USE-2 or RHH/RHW-2 PV wire MC4 connection (4)x sets (10')

($1.08/ft) batterycablesusa awg8 Marine Grade Tinned Copper Battery Cable UL 1426 (80A),(168 Stranding),(O.D. 0.27"),(0.08 lbs/ft)

$32

- 5'- no ends $8x(2) Red (combiner to scc)

- 5'- no ends $8x(2) Black (combiner to scc)

($1.42/ft) batterycablesusa awg6 Marine Grade Tinned Copper Battery Cable UL 1426 (120A),(266 Stranding),(O.D. 0.340"),(0.123 lbs/ft)

$32

-4'-5/16" lug one end $8 x(2) Red (SCC to Distributor)

-4'-5/16" lug one end $8 x(2) Black (SCC to Distributor)

($2.18/ft) batterycablesusa awg4 Marine Grade Tinned Copper Battery Cable UL 1426 (160A),(420 Stranding),(O.D. 0.405"),(0.185 lbs/ft)

$22

-4' 5/16"(m8) to No Lug $11x(1) Red (Distributor to Pheonix)

-4' 5/16"(m8) to No Lug $11x(1) Black (Distributor to Pheonix)

($10.66/ft) batterycablesusa awg4/0 Marine Grade Tinned Copper Battery Cable UL 1426 (445A),(2109 Stranding),(O.D. 0.735")(0.826 lbs/ft)

$360

- 6" 5/16"(m8) to 1/4"(m6) $13x (3) Red (Positive Battery Terminal to T fuse Block)

- 3' 5/16"(m8) to 1/4"(m6) $40x (3) Red (T fuse block to Power In)

-3' 5/16"(m8) to 5/16"(m8) $40x (3) Black (Negative Battery Terminal to Power In)

-6" 5/16"(m8) to 3/8"(m10) $13x (2) Red (Positive Power In to shutoff) (Shutoff to Lynx Shunt Postive)

-15" 5/16"(m8) to 5/16"(m8) $21x (1) Black (Negative Power In to Lynx Shunt Negative)

Total $738

Ferrules

(8)x 10awg pv inputs to combinerbox

(12)x 6awg (8)x combiner to SCCs,(4)x SCCs to Distributer)

(2)x 4awg Pheonix to Distributer

(suggestions here please)

>>> Ferrule supplier brand __________?

$__

>>> Klien crimper tool model #__________ ?

$__

Ring Lug Terminals

(specified and added when ordering wire)

Fuses

$57x(3) Blue Sea Systems Fuse Block 5007100 Class T Ignition Protected 160-200A, Maximum Torque (21.47 Nm), 72 in-lb (8.13 Nm) Mounting Fastner Size 1/4" (M6) Terminal Stud Size 1/4" (M6), (Battery Terminal Side of Bank Cable)

$43x(3) Blue Sea Systems 5114 Fuse A3T/Class T 150A Boating Fuse A3T/Class T 150A

$15 signaturesolar Victron MEGA-fuse 125A/32V (5-Pack) ((1)x Distributer Pheonix 24/1200)

$13 amazon 2x Littelfuse 60a 32v mega 0298060

$24 amazon Buss/Ferraz CNN 400A 48v

Total $447 (+ferrules/crimper)

Accessories:

$25 Ve.direct Bluetooth Dongle

$70 Victron Pheonix 12/375 (allows an earlier use of system in a 12v stage)

System Total $5955

Last edited: