chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,192

Move to 24 volts for half the amps….What are all you class T absolutists doing about fusing for over 500a?

Move to 24 volts for half the amps….What are all you class T absolutists doing about fusing for over 500a?

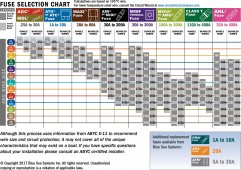

I got the (I guess wrong) impression that 400a was max from reading the Blue Sea fuse selection chart and seeing that the maximum class T size was 400 amp. Also, The marine stores I frequent seem to only carry up to 400 amp. Here is a link to the chart:

Unless there's something I'm missing?

System is still being assembled. 16x 280 EVE LiFePo4 cells, 4P4S.I have one battery feeding four inverters. I have two class T fuses, one for each two inverters.

How are your batteries wired? Are they lithium or lead-acid?

Maybe 6, 2V 1120 Ah cells in series? What is your peak continuous current draw, 400A? In that case you do want 500A fuse.

If you have two strings of cells in parallel, each can have one smaller fuse.

Would have suggested higher voltage, lower current.

I wish. This is retrofitting a boat, which already has two electric 12v winches, and electric 12v windless, and a couple of other high amperage 12v loads that would be cost prohibitive to replace.Move to 24 volts for half the amps….

All my loads are individually fused. From the factory, my boat's AGM battery bank has no battery bank fuse. There are short 150mm2 (aprox 300MCM) wires leading from the battery bank to a distribution panel. Here individual loads are fused. For example, 200a fuses to each winch, 160a for windlass, 250a for main service panel, and many more. I'm adding a battery bank fuse out of an abundance of caution. It has been a bit of a puzzle figuring out sizing. If I add up all possible loads (winches, windlass, inverter, etc) it would add up to over 600a. However, it would be nearly impossible to do (electric winches would never be used at same time as electric windlass, and so on). Also, winches tend to be used for a few seconds at a time, not continuous duty. So my idea for the battery fuse would be to size it to protect the wiring going from the battery bank to the distribution panel. Best as I can tell (300MCM is off the charts of most marine ampacity charts I've found) those wires should carry over 500 amps. So I chose a 500a fuse. Maybe a 400a fuse would be a better choice and allow better margin, but I do worry about popping that fuse when my new (yet to be installed) victron Multiplus 12/3000 briefly pulls surge current, and I have other loads going. The Multiplus manual recommends a 400a fuse, and 2/0 wires (which according to my ampacity chart can only carry 330 amps?!). Anyway, I'm still a bit adrift about best choice for a main battery bank fuse (class T? 400a?).For 250A continuous, 1.25x would suggest > 312A fuse rating.

From the following chart, a 200A fuse carrying 400A is expected to blow in just about 20 seconds. That would vary with ambient temperature.

400A fuse is showing carrying 400A way beyond 300 seconds.

350A isn't shown on this chart, but you should be able to find elsewhere.

Whatever fuse you use, wires and everything else in the path should have ampacity at least as great as fuse rating. Easier to do with 350A than 500A fuse.

You could instead have a couple fused loads, if no single load is going to draw that much current.

Thinking about time to blow is really useful, thanks for pointing that out. Also, I think mystery solved as far as the 400amp "limit". 400amp is simply the max amperage for the size that fits marine Blue Sea fuse blocks. There are larger fuses and fuse blocks available, but expensive.For 250A continuous, 1.25x would suggest > 312A fuse rating.

From the following chart, a 200A fuse carrying 400A is expected to blow in just about 20 seconds. That would vary with ambient temperature.

400A fuse is showing carrying 400A way beyond 300 seconds.

350A isn't shown on this chart, but you should be able to find elsewhere.

Whatever fuse you use, wires and everything else in the path should have ampacity at least as great as fuse rating. Easier to do with 350A than 500A fuse.

You could instead have a couple fused loads, if no single load is going to draw that much current.

If you can make a 400 amp work, BH has ACK forklift battery fuses for $10 each. You can't beat the price, and they interrupt 10ka. It's not a class T, but it would work. They also let much more than 400 amps through for short periods, as long as your continuous draw is under 400a, than it could easily take surges of 6-700a for a few seconds.The highest rated class T fuse I’ve been able to find is 400 amp. I’ve decided that my 1120ah 12v system should have a 500a fuse. The only one I’ve found at that rating is ANL. What are all you class T absolutists doing about fusing for over 500a?

batteryhookup.com

batteryhookup.com

Interesting, thanks. I wonder if fuse blocks are available for this thing. I’m probably going to stick with class T, because they are available everywhere, and I’ve never seen nor heard of this ACK fuse.If you can make a 400 amp work, BH has ACK forklift battery fuses for $10 each. You can't beat the price, and they interrupt 10ka. It's not a class T, but it would work. They also let much more than 400 amps through for short periods, as long as your continuous draw is under 400a, than it could easily take surges of 6-700a for a few seconds.

Ferraz Shawmut ACK 400 0-125VDC 400a Fuse

Here are Ferraz Shawmut 400a bolt on fuses. These are the best fuses for high current applications. These are the best DC fuses for batteries and are also approved for forklift applications. They will work with any voltage from 0-125v. Salvaged from forklift battery packs and fully tested...batteryhookup.com

I changed mine to 5 seconds and I believe it is at 130 amps. Any fuse should be fine at 200 amps.The specs on my Overkill BMS says it takes 10 seconds for this over current protection to kick in. For a 100 amp system at operating at 120 amps, that's quicker than my fuse is likely to blow, but with 200 amps being pulled from the batteries, the fuse would blow near instantly.

Class T fuses increase in size (in groups) with increasing current rating. The Blue Sea class T fuse holders (two sizes) only accommodate 110-400A fuses. Below and beyond that (and the fuses go much higher in capacity), you need to provide your own mounting system.I got the (I guess wrong) impression that 400a was max from reading the Blue Sea fuse selection chart and seeing that the maximum class T size was 400 amp. Also, The marine stores I frequent seem to only carry up to 400 amp. Here is a link to the chart:

http://assets.bluesea.com/files/resources/newsletter/images/Choose_the_Fuse_Amperage.jpgView attachment 61620

Which manufacturer?I still can't get over a major manufacturer employing Mega fuses in this situation, when they are only rated by the inventor/manufacturer (Littlefuse) to interrupt 2000A at 32VDC!