Hi

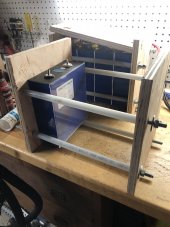

@S Davis. I have a further question: Do you have anything supporting the cells on the bottom of the compression rig? Or are they directly resting on what looks like an aluminum plate in the photo?

I really like your setup, and I'm trying to design something similar in my build. As that's a very heavy load for my camper I was thinking of placing it closer to the cab and having the two water tanks on each side, this way I have the best weight balance. But I want the cells to be suspended a bit from the floor so that in case of any leaks or flooding in the camper they don't short out. Hopefully, it will never happen, but better safe than sorry. You also have the enclosure on the outside that can be sealed, but I feel like that adds unnecessary weight and I'm looking for something alternative.