fisherman

New Member

Good Morning,

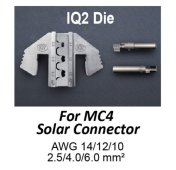

I haven't been able to come to a conclusion on what MC4 crimper to buyand haven't found much using the search function on the forum on this.

Would anyone have recommendations on what is working for them when crimping MC4?

Thank you

I haven't been able to come to a conclusion on what MC4 crimper to buyand haven't found much using the search function on the forum on this.

Would anyone have recommendations on what is working for them when crimping MC4?

Thank you