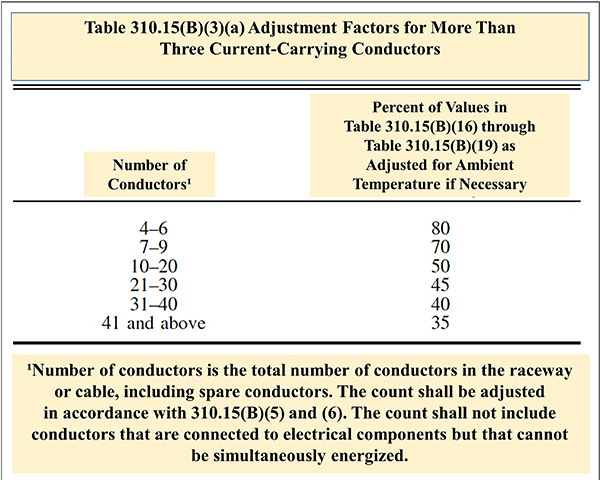

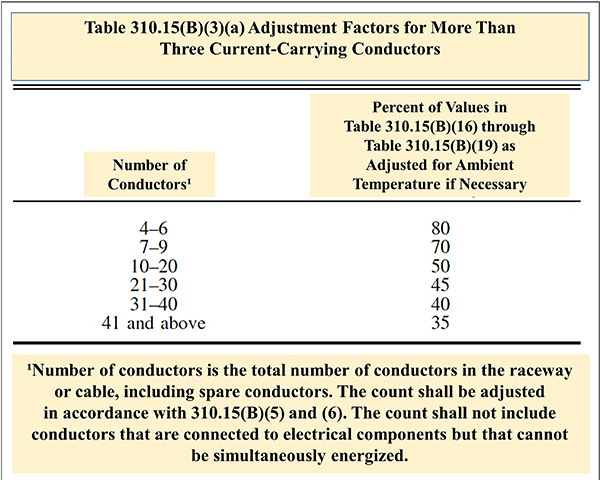

310.15(B)(3)(a) Adjustment Factors for More Than Three Current-Carrying Conductors.

Click to Enlarge

Use the image to help answer the question.

Table 310.15(B)(3)(a) provides adjustment factors when installing more than three

current-carrying conductors (CCC). Years ago, the table only applied when there were more than three CCC “in a raceway or cable”. The adjustment factors in the table are required for more than just raceway or cable installations containing more than three CCC.

A good example of this is when separate cables are installed without maintaining spacing. For these installations, if cables are bundled for a continuous length longer than 24 in., the allowable ampacity of each conductor must be reduced as shown in Table 310.15(B)(3)(a).

The table also applies to spare conductors. Often, spare conductors that have been installed for future use will eventually become current carrying conductors.

The table does not apply when conductors cannot be energized simultaneously. For example; There is no need to consider two travelers to a 3-way switch as two current carrying conductors since only one of the two can be energized at any given time.

It is important to remember that temperature correction and adjustment factors are permitted to be applied to the ampacity column in Table 310.15(B)(16) for the specific temperature rating of the conductor, as long as the corrected and adjusted ampacity does not exceed the ampacity for the temperature rating of the conductor terminal in accordance with 110.14(C).

For example, an 8 AWG, THHN copper conductor has an ampacity of 55 amps in the 90°C column of Table 310.15(B)(16) and 50 amps in the 75°C column.

If the 90°C wire is connected to a circuit breaker marked with 75°C terminals, and installed in a raceway with a total of 4 CCC (which requires an 80% adjustment factor), then the math can begin at the maximum rating of the wire which is 55 amps as long as the final adjusted value does not exceed 50 amps in the 75°C column since the lower temperature rated terminals are the weakest link in the circuit:

55 X 80% = 44 amps.