rebelrider.mike

New Member

I live in a 1941 cinder block house. Its all-electric; no natural gas hookup.

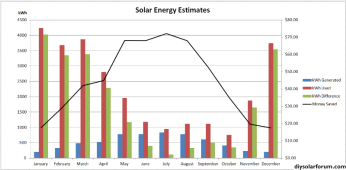

My energy usage varies from 800-5,000kWh per month depending on the time of year.

I've decided to "burn the candle at both ends" and work on increasing my house's efficiency as well as trying to be less dependent on the grid. I've been working on the efficiency side for many years, and have made some progress:

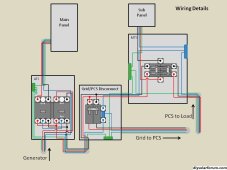

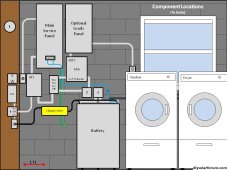

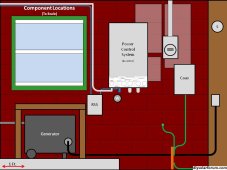

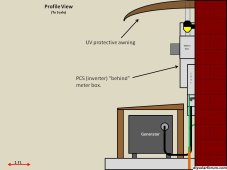

At the same time, I've been researching inverters, PV systems, and batteries for quite a while. One thing I'm realizing is that I really need a sub panel. As I've been upgrading my house electrical, code has required me to add more breakers to my already crowded main panel. Adding a sub panel will allow me to have an "optional loads" panel separate from the main panel, and also make room for future circuits on the main panel. I've been working on clearing a space for my future "power wall".

I also got one of those Vue energy monitors to help me decide which circuits to move to the sub panel. That's what all the white junk hanging out of the panel is.

The first real decision I had to make was whether or not to comply with NEC. My state uses the 2020 cycle. It took a long time, but ultimately I decided to comply and get inspections. This will make things more difficult and expensive in the short term, but I think the long term benefits will be worth it. This means that not only have I needed to dive into how all this solar/battery/inverter stuff works, but I've also had to dive into the NEC, and attempt to decode it. So this thread is going to have a lot of NEC terminology mixed in.

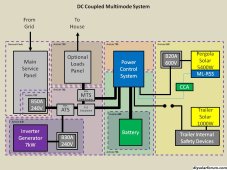

The next decision was what kind of system do I want? I found lots of different ways to do things. Each way is the right way for someone. For me, I chose what the NEC calls a DC coupled multimode system. DC coupled as in a hybrid inverter that can use both solar and battery. Multimode as in the inverter can operate in both grid-interactive mode and island mode. I chose this because it fits with my priorities:

My energy usage varies from 800-5,000kWh per month depending on the time of year.

I've decided to "burn the candle at both ends" and work on increasing my house's efficiency as well as trying to be less dependent on the grid. I've been working on the efficiency side for many years, and have made some progress:

- 19 single pane windows have been replaced with modern double pane windows.

- Kitchen exterior door was made of a single sheet of plywood, and some framing, the window was a single pane sheet of plastic, and water leaked into the basement whenever it rained. Well, that's been replaced with a modern insulated door with a double pane window. Also, the door frame was replaced. No more leaks!

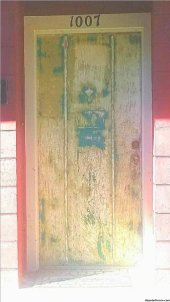

- The front exterior door is very old and was in need of repairs. Rather than replace it, I took it down and refurbished it. Many layers of old paint was removed, and damaged areas were replaced with new wood. The plan is to improve the door frame too, and add a storm door.

At the same time, I've been researching inverters, PV systems, and batteries for quite a while. One thing I'm realizing is that I really need a sub panel. As I've been upgrading my house electrical, code has required me to add more breakers to my already crowded main panel. Adding a sub panel will allow me to have an "optional loads" panel separate from the main panel, and also make room for future circuits on the main panel. I've been working on clearing a space for my future "power wall".

I also got one of those Vue energy monitors to help me decide which circuits to move to the sub panel. That's what all the white junk hanging out of the panel is.

The first real decision I had to make was whether or not to comply with NEC. My state uses the 2020 cycle. It took a long time, but ultimately I decided to comply and get inspections. This will make things more difficult and expensive in the short term, but I think the long term benefits will be worth it. This means that not only have I needed to dive into how all this solar/battery/inverter stuff works, but I've also had to dive into the NEC, and attempt to decode it. So this thread is going to have a lot of NEC terminology mixed in.

The next decision was what kind of system do I want? I found lots of different ways to do things. Each way is the right way for someone. For me, I chose what the NEC calls a DC coupled multimode system. DC coupled as in a hybrid inverter that can use both solar and battery. Multimode as in the inverter can operate in both grid-interactive mode and island mode. I chose this because it fits with my priorities:

- Using less electricity from the grid.

- Having some electricity available when the grid is down.

- Being able to cope with long-term power outages if such a thing happens.

- Having a positive impact on the environment would be great. Not sure I'll actually achieve that though.

- Becoming completely independent from the grid.

- Powering my whole house during a grid outage.

- Trading dependence on the grid for dependence on a generator or natural gas.

- Reluctantly, saving lots of money. (I'll get into this later.)