SenileOldGit

Solar Enthusiast

- Joined

- Oct 15, 2022

- Messages

- 320

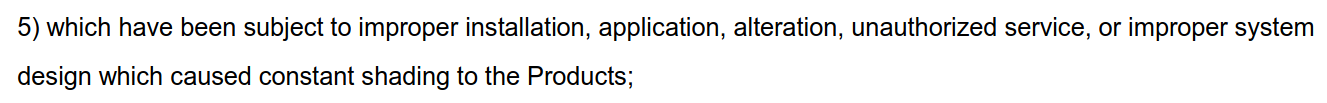

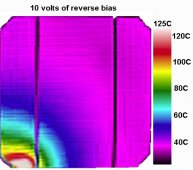

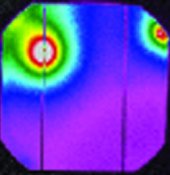

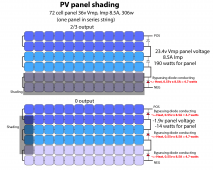

I have been reading up about bypass diodes, and I noticed that the guarantee for my Canadian Solar panels states that they mustn't be in shade for more than 100 hours, or something like that, and I have a large tree that is currently shading my panels for several hours of the day, which I am going to have severely cut back - but has anybody here ever had a panel fail because of shading? I presume that first the bypass diode(s) have to fail, which would then force the electricity from the unshaded panels to go through the solar cells in the shaded panel itself, thus causing excess heat in the solar cells?

I presume that as soon as a bypass diode fails, you would see a marked drop in the output of your string, because that panel really will 'bring the other panels down' to its level - I wonder how long a panel can last when a bypass diode (or all three bypass diodes) have failed, and it's in shade? Have any tests been done of this? It should be pretty easy, buy a £200 panel, or a secondhand one that isn't too old, and remove the bypass diodes, put it into a string, and see what happens to it.

I presume that as soon as a bypass diode fails, you would see a marked drop in the output of your string, because that panel really will 'bring the other panels down' to its level - I wonder how long a panel can last when a bypass diode (or all three bypass diodes) have failed, and it's in shade? Have any tests been done of this? It should be pretty easy, buy a £200 panel, or a secondhand one that isn't too old, and remove the bypass diodes, put it into a string, and see what happens to it.

Last edited: