Greetings,

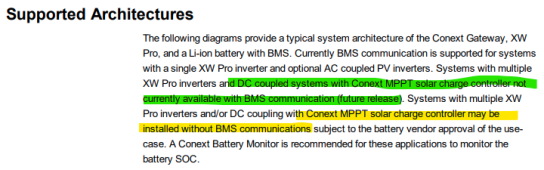

I have an AC coupled XW Pro 6848 integrated with a BMS (Pylontech emulation – recognized by Insight Home). The integration is not perfect. When charging from the grid, and the BMS instructs the inverter to reduce the amps (from 140 to 15 {charging allowed but at reduced amps}), the inverter just stops charging for a while (until the BMS restore the amps to the previous value) and then resume. It’s not ideal, but works. During grid outages the inverter noise (during the day, just when ac coupled) drives me crazy. Because of that I’m going to add a couple of panels what were purchased previously. I bought a Conext MPPT 60 150. But I’m not sure if that was the right decision. Does the Conext MPPT 60 ‘talks’ with the BMS like the inverter does? If the BMS is recognized by Insight Home and the Conext MPPT 60 is connected to the Xanbus. Will the Conext stop charging when the BMS send the stop charging command? I just want to prevent a ‘hard’ shutdown (BMS turn off the contactor). Do not care if the Conext MPPT ignores the charge amps like the inverter does. Thank you very much.

I have an AC coupled XW Pro 6848 integrated with a BMS (Pylontech emulation – recognized by Insight Home). The integration is not perfect. When charging from the grid, and the BMS instructs the inverter to reduce the amps (from 140 to 15 {charging allowed but at reduced amps}), the inverter just stops charging for a while (until the BMS restore the amps to the previous value) and then resume. It’s not ideal, but works. During grid outages the inverter noise (during the day, just when ac coupled) drives me crazy. Because of that I’m going to add a couple of panels what were purchased previously. I bought a Conext MPPT 60 150. But I’m not sure if that was the right decision. Does the Conext MPPT 60 ‘talks’ with the BMS like the inverter does? If the BMS is recognized by Insight Home and the Conext MPPT 60 is connected to the Xanbus. Will the Conext stop charging when the BMS send the stop charging command? I just want to prevent a ‘hard’ shutdown (BMS turn off the contactor). Do not care if the Conext MPPT ignores the charge amps like the inverter does. Thank you very much.