I currently have three US5000 pylontech batteries working great with a Solis Hybrid inverter.

They are not quite big enough for daily use, particularly in winter when I charge them overnight to run the home during the day.

So thinking about upgrading by putting together a 15S pack of LF280K with a JK-BMS as I'll get an extra ~13kWh for the cost of one additional 4.8kWh US50000.

15S to match the 15S configuration of the pylontech packs so they will charge and discharge in balance.

But the question comes down to if the system will get confused if I leave the CAN bus interface connected between the inverter and pylontech batteries ? The idea being that I attach the DIY pack in parallel with the pylontech batteries under private supervision from the JK-BMS, and leave the pylontech pack to do any necessary communications with the inverter through CAN. The inverter nor pylontech pack will not know that the DIY pack exists. If the DIY pack gets in trouble it will disconnect through the JK-BMS.

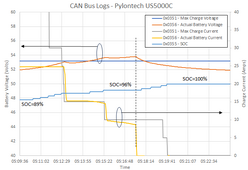

I've spent the last few days eavesdropping on the CAN bus between inverter and pylontech to test the idea, but can't quite work out who is the master. Inverter or battery.

The pylontech protocol doesn't appear to be clear on this point.

For example :

I set my inverter to charge the pylontech at 11:30pm every night.

I see the pylontech report to the inverter a change in the expected charge current when charging commences actioned from the inverter.

However, at 5am when the pylontech is fully charged, I see the pylontech report a gradual reduction in charge current as it nears 100%. But is this commanded by the battery or actioned by the inverter when it sees the battery nearing 100% SOC ?

Running the DIY pack in parallel with the pylontech will cause ~50% of charge current to be shared between pylontech and DIY pack.

So am I at risk here of the Solis inverter detecting a charge current that does not then tally with that reported from the pylontech CAN bus and the system throwing an error ?

Has anyone got any detailed experience of the pylon CAN bus to know whether this idea of adding a dumb pack in parallel is a non starter. Or will I need a babel fish to fuse the current data between pylontech and JK-BMS into a single coherent CAN bus stream to get this to work ?

They are not quite big enough for daily use, particularly in winter when I charge them overnight to run the home during the day.

So thinking about upgrading by putting together a 15S pack of LF280K with a JK-BMS as I'll get an extra ~13kWh for the cost of one additional 4.8kWh US50000.

15S to match the 15S configuration of the pylontech packs so they will charge and discharge in balance.

But the question comes down to if the system will get confused if I leave the CAN bus interface connected between the inverter and pylontech batteries ? The idea being that I attach the DIY pack in parallel with the pylontech batteries under private supervision from the JK-BMS, and leave the pylontech pack to do any necessary communications with the inverter through CAN. The inverter nor pylontech pack will not know that the DIY pack exists. If the DIY pack gets in trouble it will disconnect through the JK-BMS.

I've spent the last few days eavesdropping on the CAN bus between inverter and pylontech to test the idea, but can't quite work out who is the master. Inverter or battery.

The pylontech protocol doesn't appear to be clear on this point.

For example :

I set my inverter to charge the pylontech at 11:30pm every night.

I see the pylontech report to the inverter a change in the expected charge current when charging commences actioned from the inverter.

However, at 5am when the pylontech is fully charged, I see the pylontech report a gradual reduction in charge current as it nears 100%. But is this commanded by the battery or actioned by the inverter when it sees the battery nearing 100% SOC ?

Running the DIY pack in parallel with the pylontech will cause ~50% of charge current to be shared between pylontech and DIY pack.

So am I at risk here of the Solis inverter detecting a charge current that does not then tally with that reported from the pylontech CAN bus and the system throwing an error ?

Has anyone got any detailed experience of the pylon CAN bus to know whether this idea of adding a dumb pack in parallel is a non starter. Or will I need a babel fish to fuse the current data between pylontech and JK-BMS into a single coherent CAN bus stream to get this to work ?