AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

It has been years of posting on this forum, realizing I'm an idiot, learning something, then doing something else for a bit and forgetting everything I thought I previously learned, only to be an idiot again and have to re-learn what I thought I knew. Years, and all before we had actually built anything. But that changed today I am thrilled to report. It's just a single ground mount, but it wasn't easy making it happen.

We're in Alaska and completely off grid. We have a helicopter deliver our stuff and we take a mile long ATV trip one thousand feet uphill to get back to our place from the nearest dirt road.

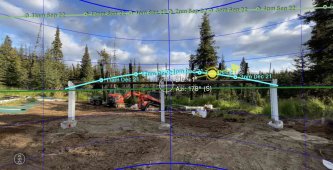

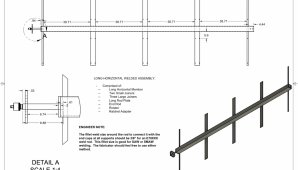

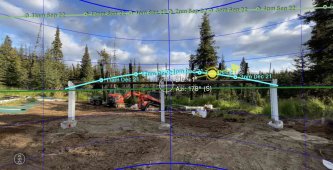

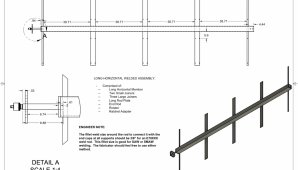

We bought 50 of the LG440N2T-E6 bi-facial panels. They appear to be great panels and the warranty was top notch. Then right after we bought them, LG got out of the solar business. We had two break in shipping. We can't even find replacements anywhere. LG support never answered a single email and we had trouble finding an off the shelf ground mount that would take advantage of their bi-facial capability. So we broke out a CAD program and designed our own mount, made the design drawings with dimensions and such, sent it all to an engineer who said our design would work but told us to make it bigger, heavier, more expensive and bury the beams deeper and encase each in 1800 pounds of concrete. Each of the three I-beams that comprise each solar array are buried 8 foot in the ground and surrounded by 1800 pounds of concrete. That gets us a couple feet of snow clearance, so I will be doing a lot of dirt work to create a downhill in front of these arrays to keep snow from blocking them.

The concrete requirement blew us away. We're off grid. We have to mix our own mud. And we require a helicopter to deliver it all because that many trips in our tracked ATV would destroy it. Needless to say, our quote from a metal fabricator to order 7 of these arrays quickly became ordering only two of these arrays as we factored in all the costs including concrete. We couldn't afford more than two this go. We'll get the five other arrays next summer hopefully.

But today, we got the first mount in the ground. It rotates and locks the panels in 0 degrees straight up and down for our winters where we don't want snow on them, 6 degrees which is our best winter angle, 15, 23, 38, 71 and 90 degrees. We will insert two bolts on either end to secure the panels in a position for the wind.

After all the grinding I had to do, followed by priming and painting, of the i-beams (two coats on the metal that is in the ground) I still have to add another coat of paint to the above ground part of the beams, weld the round "rotators" onto the assembly so that the holes on both sides match up and then grind, and prime and paint all the horizontal components. And then I can add plastic spacers and finally, finally, mount seven panels to this first mount.

Then do the same for the second array.

Then trench to the solar shed that is just about completed. Then install the battery bank, MPPTs, Quattro and bus bar in that shed and trench the 700 feet from the shed to our cabin. Then add the massive triplex aluminum wire into the 9 foot deep trench and hire an electrician to make sure it's all good and to do the grounding which is too cosmic for me especially given we will have two Victron Autotransformers in our mix.

Anyway, it's just a start but it's something tangible so we're pretty excited at the prospect of milking what little sun we get on 21 December (after I cut some trees) in the freezing cold. Many thanks to so many on this forum, and to Will, for getting us this far. Which isn't very far yet. But it's a start. Until I burn this forest down when I combine things that shouldn't touch in the coming weeks. But at least the beams will still be standing even if the trees are not.

We're in Alaska and completely off grid. We have a helicopter deliver our stuff and we take a mile long ATV trip one thousand feet uphill to get back to our place from the nearest dirt road.

We bought 50 of the LG440N2T-E6 bi-facial panels. They appear to be great panels and the warranty was top notch. Then right after we bought them, LG got out of the solar business. We had two break in shipping. We can't even find replacements anywhere. LG support never answered a single email and we had trouble finding an off the shelf ground mount that would take advantage of their bi-facial capability. So we broke out a CAD program and designed our own mount, made the design drawings with dimensions and such, sent it all to an engineer who said our design would work but told us to make it bigger, heavier, more expensive and bury the beams deeper and encase each in 1800 pounds of concrete. Each of the three I-beams that comprise each solar array are buried 8 foot in the ground and surrounded by 1800 pounds of concrete. That gets us a couple feet of snow clearance, so I will be doing a lot of dirt work to create a downhill in front of these arrays to keep snow from blocking them.

The concrete requirement blew us away. We're off grid. We have to mix our own mud. And we require a helicopter to deliver it all because that many trips in our tracked ATV would destroy it. Needless to say, our quote from a metal fabricator to order 7 of these arrays quickly became ordering only two of these arrays as we factored in all the costs including concrete. We couldn't afford more than two this go. We'll get the five other arrays next summer hopefully.

But today, we got the first mount in the ground. It rotates and locks the panels in 0 degrees straight up and down for our winters where we don't want snow on them, 6 degrees which is our best winter angle, 15, 23, 38, 71 and 90 degrees. We will insert two bolts on either end to secure the panels in a position for the wind.

After all the grinding I had to do, followed by priming and painting, of the i-beams (two coats on the metal that is in the ground) I still have to add another coat of paint to the above ground part of the beams, weld the round "rotators" onto the assembly so that the holes on both sides match up and then grind, and prime and paint all the horizontal components. And then I can add plastic spacers and finally, finally, mount seven panels to this first mount.

Then do the same for the second array.

Then trench to the solar shed that is just about completed. Then install the battery bank, MPPTs, Quattro and bus bar in that shed and trench the 700 feet from the shed to our cabin. Then add the massive triplex aluminum wire into the 9 foot deep trench and hire an electrician to make sure it's all good and to do the grounding which is too cosmic for me especially given we will have two Victron Autotransformers in our mix.

Anyway, it's just a start but it's something tangible so we're pretty excited at the prospect of milking what little sun we get on 21 December (after I cut some trees) in the freezing cold. Many thanks to so many on this forum, and to Will, for getting us this far. Which isn't very far yet. But it's a start. Until I burn this forest down when I combine things that shouldn't touch in the coming weeks. But at least the beams will still be standing even if the trees are not.